Wind power generator uncable system and uncable method thereof

A technology for wind turbines and unwinding, which is applied to wind turbines, wind turbine control, wind power generation, etc., can solve the problems of long rotation time of wind turbines, mechanical friction of parts, affecting the accuracy of unwinding, etc. Excellent line reliability, reliable and accurate acquisition, beneficial to transmission and amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

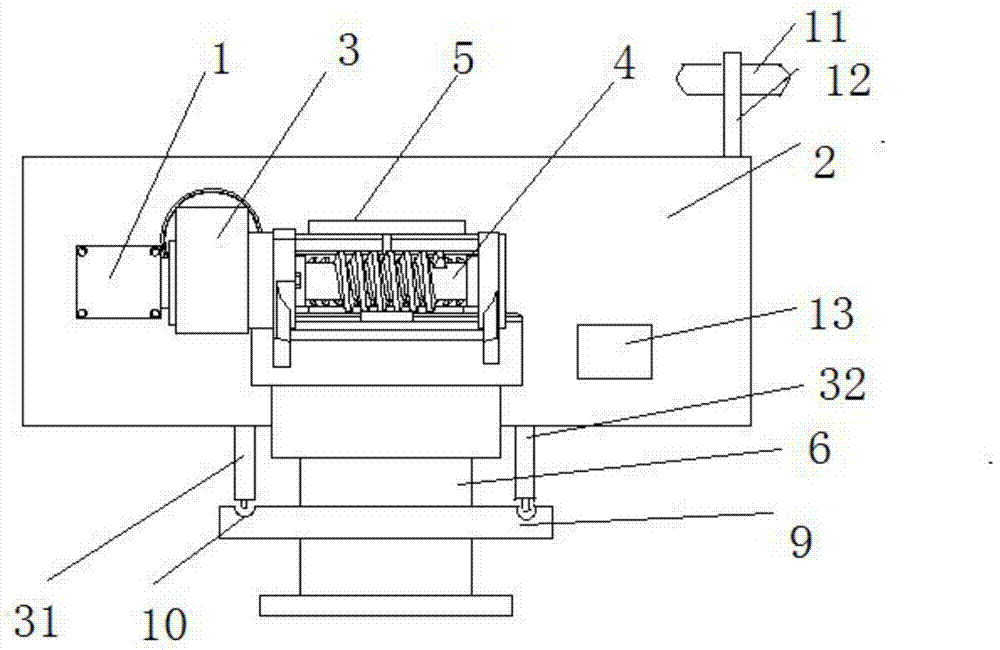

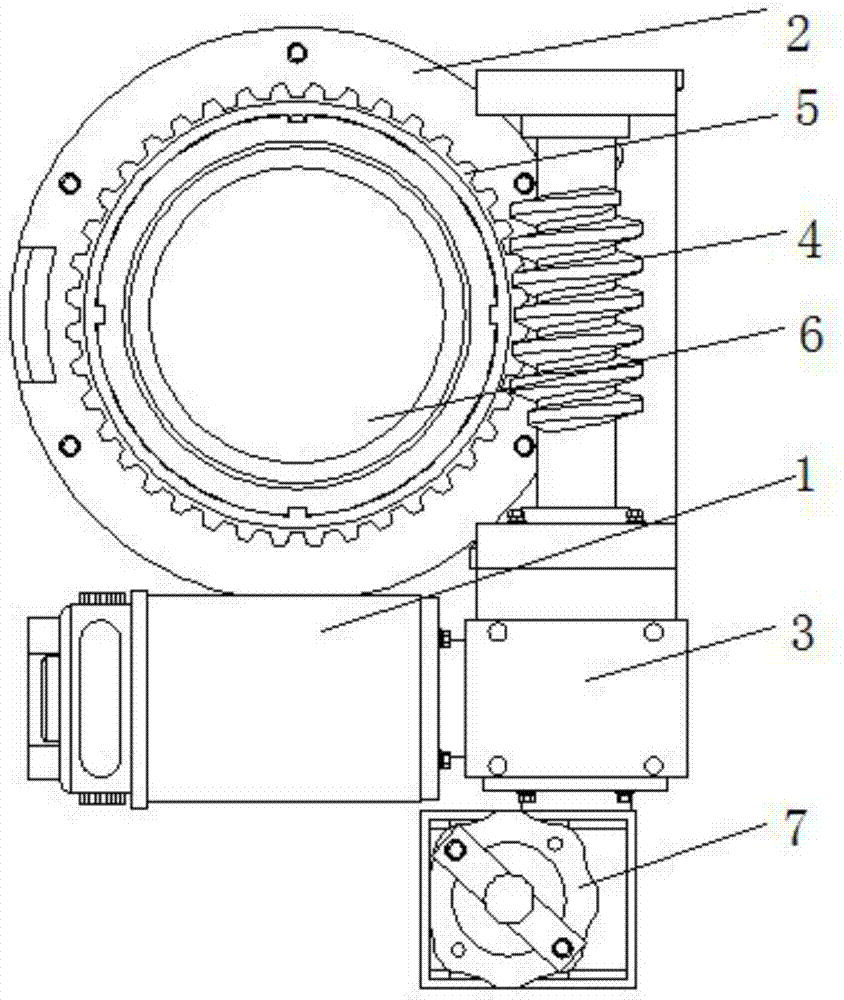

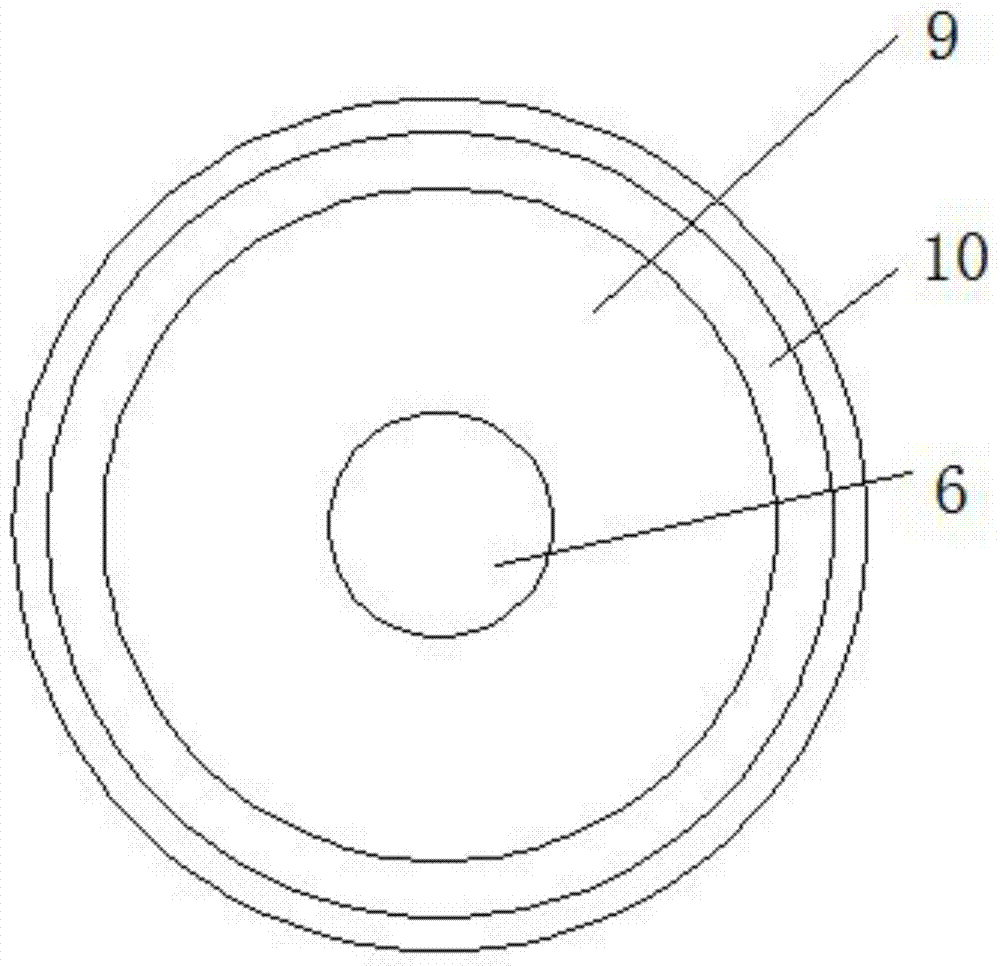

[0030] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, a wind power generator untwisting system includes a controller 13, a yaw motor 1, a wind power generator rotor 2, a worm gear reducer 3, a worm 4, a turbine 5, a wind power generator shaft 6, and an angle sensor 7. The inclination adjustment module 8 and the disk 9 are characterized in that: the controller is connected to the yaw motor 1, one end of the worm gear reducer 3 is connected to the yaw motor 1, and the other end is connected to the yaw motor 1. The worm 4 is connected, the turbine 5 is fixedly connected to the wind generator rotating shaft 6, the worm 4 is fixedly connected to the wind generator rotating body 2, the worm gear reducer 3 includes an angle sensor 7, and the disc 9 surrounds the The rotating shaft 6 of the wind power generator is fixedly connected, the normal direction of the surface where the disk 9 is located is the same as the axial direction of the rotating shaft 6 of the wind p...

Embodiment 2

[0051] A wind-driven generator uncable system, comprising a controller, a yaw motor, a wind-driven generator rotating body, a worm gear reducer, a worm, a wind-driven generator rotating shaft, an angle sensor, an inclination adjustment module, and a disc, characterized in that: The controller is connected to the yaw motor, one end of the worm gear reducer is connected to the yaw motor, and the other end is connected to the worm, and in Embodiment 1, the turbine is fixed to the rotor of the wind power generator connected, the turbine is located at the upper end of the rotor of the wind power generator, and the part connecting the rotor of the wind generator to the turbine is the outer ring of the rotary support. In this embodiment, there is no turbine, and the outer ring of the rotary support is directly processed into a turbine. shape, the worm is fixedly connected to the wind generator rotor, the worm gear reducer includes an angle sensor, the wind generator rotor is fixedly c...

Embodiment 3

[0061] Such as figure 1 , figure 2 , image 3 As shown, a wind power generator untwisting system includes a controller 13, a yaw motor 1, a wind power generator rotor 2, a worm gear reducer 3, a worm 4, a turbine 5, a wind power generator shaft 6, and an angle sensor 7. The inclination adjustment module 8 and the disk 9 are characterized in that: the controller is connected to the yaw motor 1, one end of the worm gear reducer 3 is connected to the yaw motor 1, and the other end is connected to the yaw motor 1. The worm 4 is connected, the turbine 5 is fixedly connected to the wind generator rotating shaft 6, the worm 4 is fixedly connected to the wind generator rotating body 2, the worm gear reducer 3 includes an angle sensor 7, and the wind generator rotating body 2 The first inclination adjustment module, the second inclination adjustment module and the third inclination adjustment module are fixedly connected, and the disk 9 is fixedly connected around the rotation axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com