Novel common rail oil injector

A common rail fuel injector and fuel injector technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve problems such as high temperature, affecting the stability and reliability of fuel injectors, limiting fuel injection pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

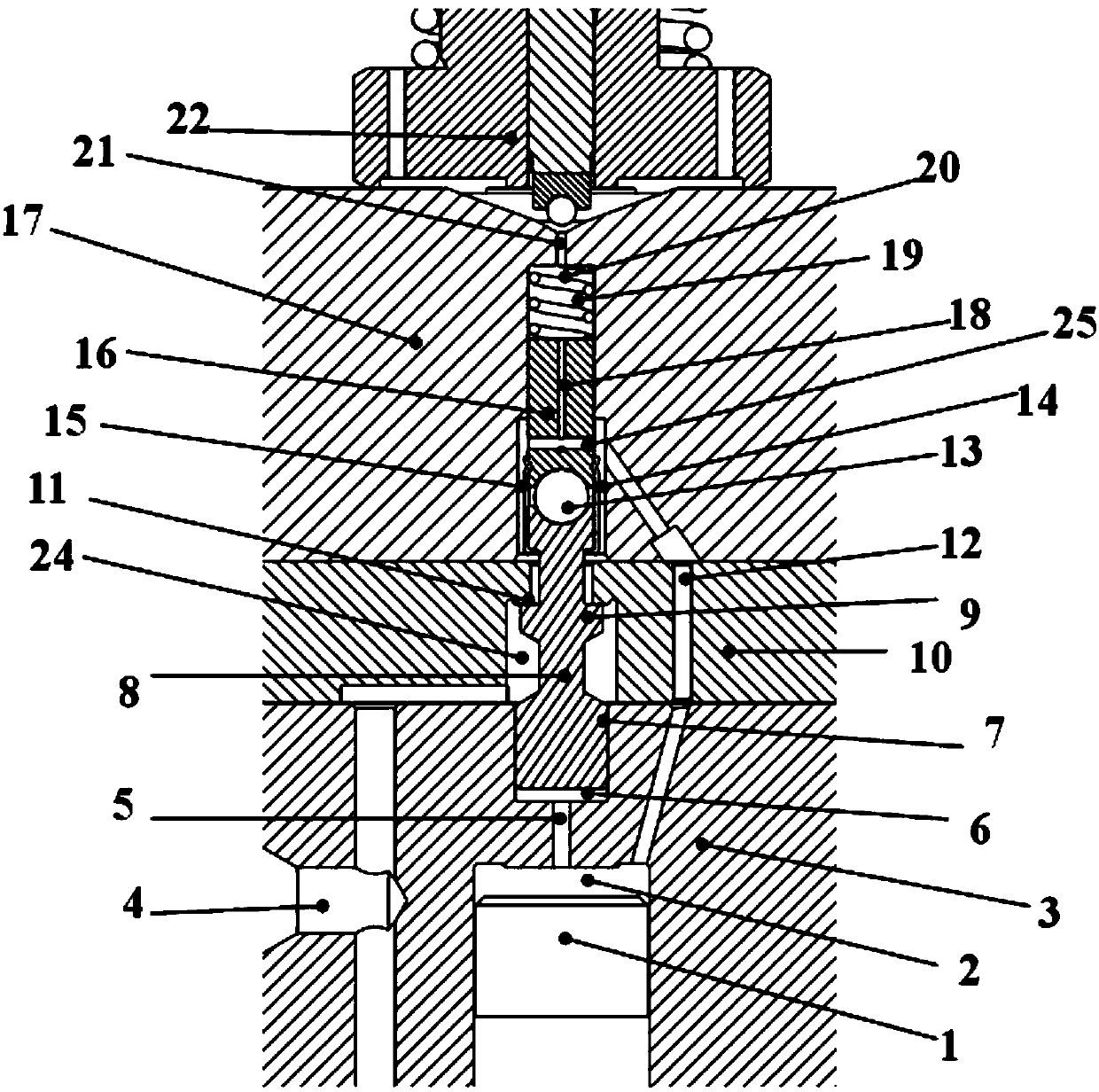

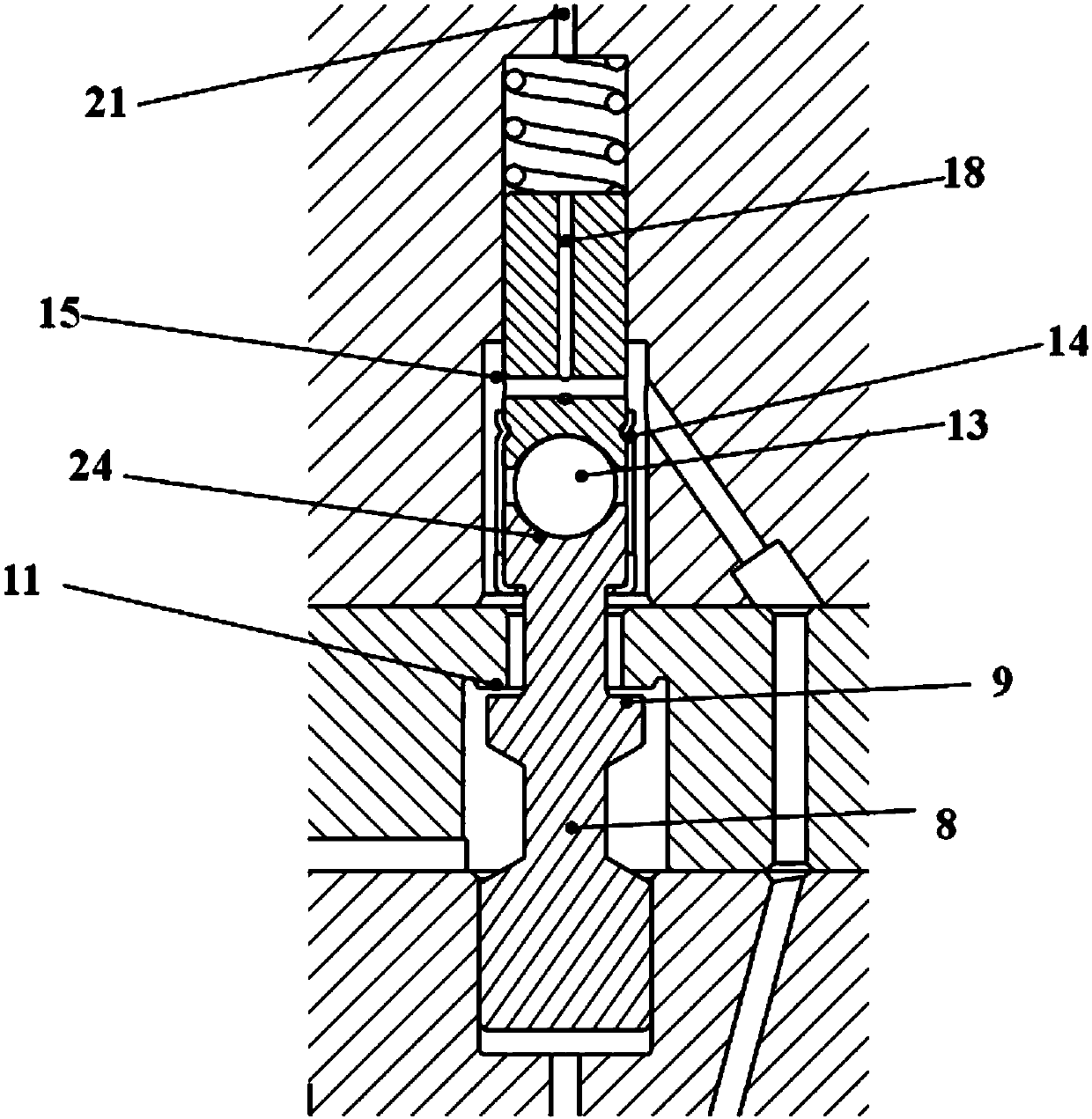

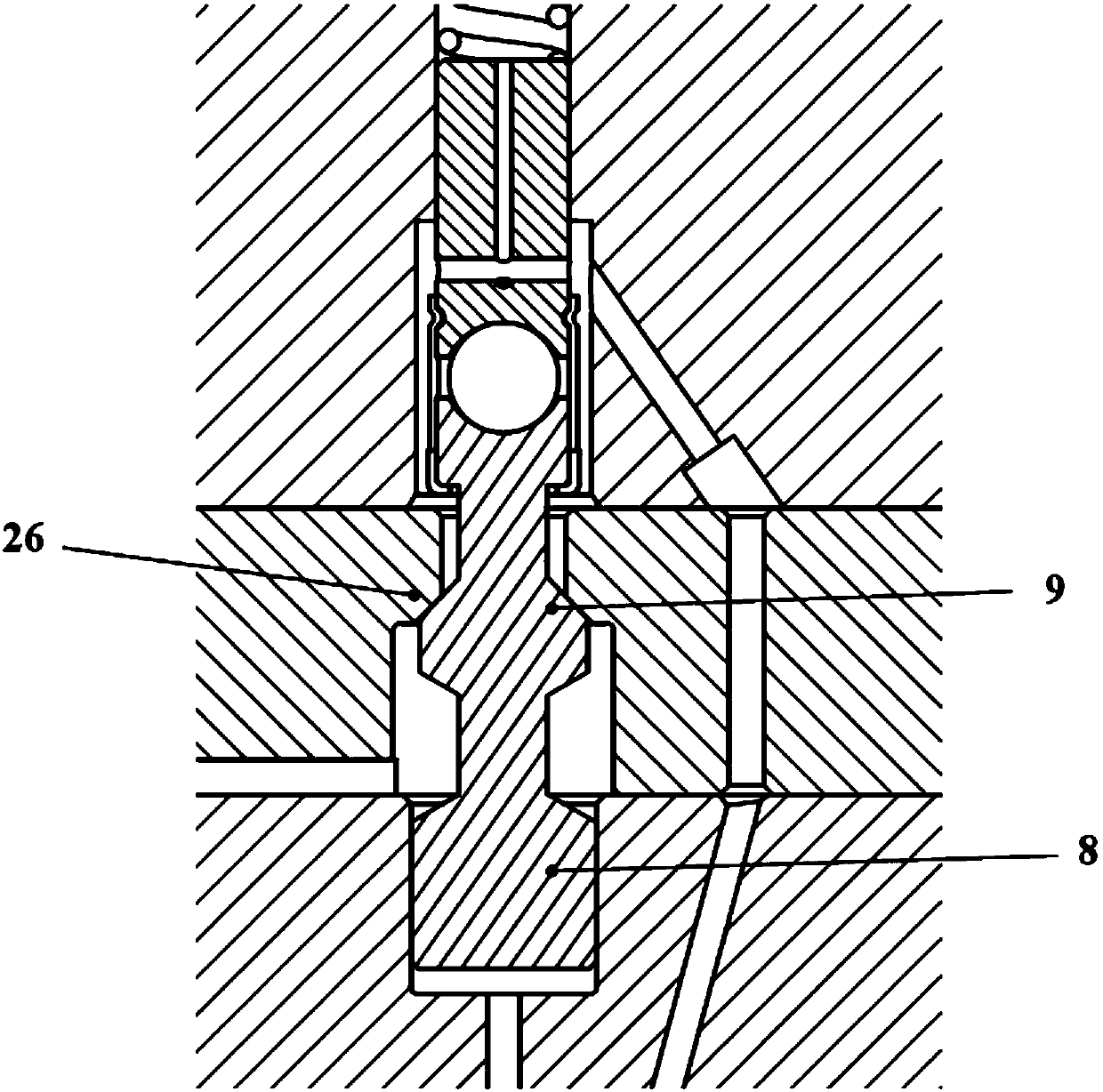

[0030] A new type of common rail injector control cavity in the present invention can refer to the attached figure 1 , 2 description of.

[0031] The sliding spool composed of the control piston 1 of the injector, the injector body 3, the orifice plate A 10, the orifice plate B 17, the spool C 8 and the spool D 16, and the ball valve 22 form the control valve. The control chamber 2 has only one oil passage connected to the high-pressure oil passage and the low-pressure oil passage. This oil passage is both the oil inlet passage and the oil outlet passage of the control chamber 2, and there is no throttle hole. The control chamber 2 on the top of the injector body 3 has two oil passages, one oil passage is connected with the high-pressure oil passage and the low-pressure oil passage, and the other oil passage G5 is connected with the bottom oil chamber 6 of the spool C8 to prevent the spool from Oil resistance occurs during the movement, and the bottom 7 of the spool C is gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com