Nano lotus fiber/alginate porous material and preparation method thereof

A technology of porous material and lotus fiber is applied in the field of nano lotus fiber/alginate porous material and its preparation, which can solve the problems of easily damaging human cells and tissues, and achieve the effects of low cost, convenient use and good water absorption.

Inactive Publication Date: 2015-01-07

QINGDAO UNIV

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Common chemical cross-linking agents in the prior art, such as hexamethylene glycol dihydrazide, polyethylene glycol-diamine and other dihydrazines or diamines, are toxic and difficult to completely remove, and are easy to damage human cells and tissues after use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0041] 0.02% of nanometer lotus fiber, 1.3% of oxidized sodium alginate, 0.6% of carboxymethyl chitosan, and the balance is solvent.

Embodiment 2

[0043] 0.05% of nano lotus fiber, 1% of oxidized sodium alginate, 10% of carboxymethyl chitosan, and the balance is solvent.

Embodiment 3

[0045] 0.08% of nanometer lotus fiber, 1.3% of oxidized sodium alginate, 5% of carboxymethyl chitosan, and the balance is solvent.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Login to View More

Abstract

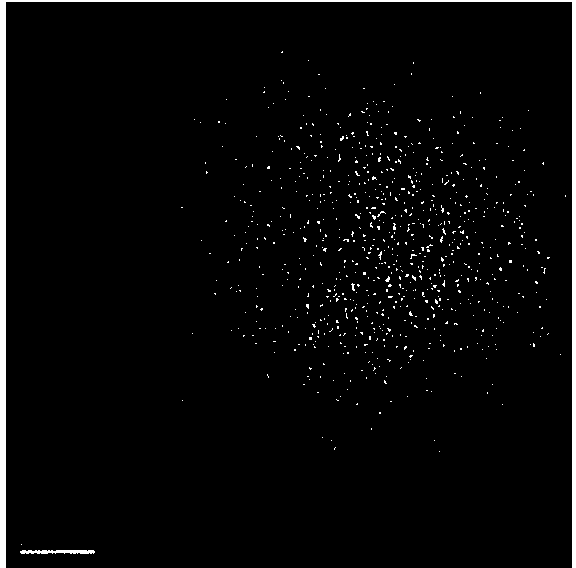

The invention discloses a nano lotus fiber / alginate porous material and a preparation method thereof and belongs to the fields of preparation of the porous materials and processing and utilization of sodium alginate. The porous material is prepared from 0.02wt%-0.08wt% of nano lotus fibers, 1wt%-20wt% of oxidized sodium alginate, 0.6wt%-10wt% of carboxymethyl chitosan and the balance of solvent, wherein the solvent is one selected from deionized water, distilled water, normal saline, water for injection and ringer's solution. The nano lotus fiber / alginate porous material is obtained by crosslinking at a temperature in the range of 20 to 50 DEG C with nano lotus fibers as a reinforcer, the oxidized sodium alginate a base material and the carboxymethyl chitosan as a crosslinking agent. The prepared nano lotus fiber / alginate porous material is capable of degrading a biomaterial in short time, relatively low in cost, convenient to use, and non-toxic and antibacterial to a human body, and has excellent water-absorbing quality, biodegradability and biocompatibility.

Description

technical field [0001] The invention relates to the field of preparation of medical porous materials and the processing and utilization of sodium alginate, in particular to a nanometer lotus fiber / alginate porous material with oxidized sodium alginate as a base material and a preparation method thereof. Background technique [0002] The choice of biomaterial determines the biocompatibility of the constructed porous scaffold material. Sodium alginate is a natural material extracted from seaweed plants, and is one of the natural biomaterials approved by the US Food and Drug Administration (FDA) for use in medical fields such as tissue engineering. Sodium alginate, a polysaccharide, has a similar structure to aminoglycans, a component of the skin dermal matrix, and has good biocompatibility. Skin fibroblasts, liver cells, chondrocytes, and osteoblasts are easily absorbed in alginate porous materials. In addition, sodium alginate also has good film-forming, gelling, hygroscopic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L5/04C08L5/08C08L97/02C08J9/28C08J3/24C08B37/04

Inventor 韩光亭宫英张元明

Owner QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com