Underground mine vehicle spray washing method and system

A mining and vehicle technology, applied in the field of control, can solve the problems of small underground safety clearance and injury accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

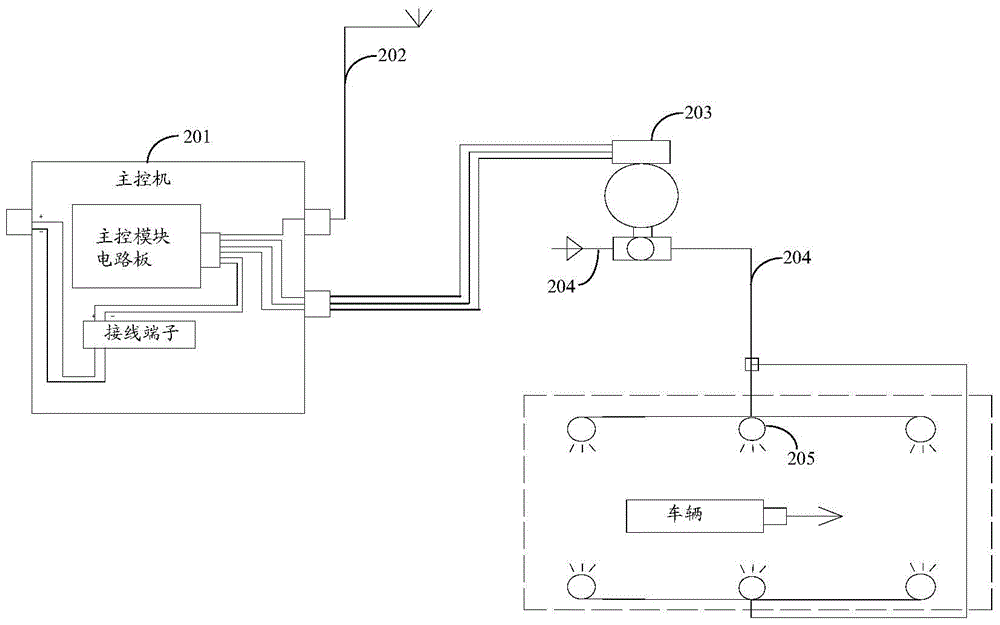

[0031] See figure 1 , figure 1 This is a flow chart of a spray washing method for underground mining vehicles provided by an embodiment of the present invention. The spray washing method for underground mining vehicles provided by the embodiment of the present invention is applied to a spray washing system for underground mining vehicles. The system includes an electric ball valve, a high-pressure water pipe connected to the electric ball valve, and a high-pressure water pipe. Nozzles, such as figure 1 As shown, the method includes:

[0032] Step S101, detecting a start spraying instruction;

[0033] Specifically, when the underground mining vehicle needs to be cleaned, the driver drives the underground mining vehicle into the spray washing area, and then manipulates the start button of the remote control to trigger the remote control to transmit a wireless control signal, that is, the start spray washing instruction is remotely controlled by the driver The device is issued. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com