Manufacturing method of middle sole and middle sole

A production method and technology of glass fiber cloth, which is applied in the field of shoe manufacturing technology, can solve the problems of increasing defective products, easy softening, affecting standardization and standardization, etc., and achieve the effect of improving balance, high strength of finished products, and convenient standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the principle and structure of the present invention, the preferred embodiments of the present invention are now described in detail in conjunction with the accompanying drawings, but the embodiments are only for illustration and explanation, and cannot be used to limit the scope of patent protection of the present invention.

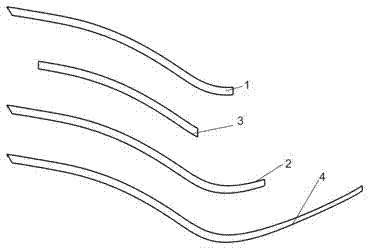

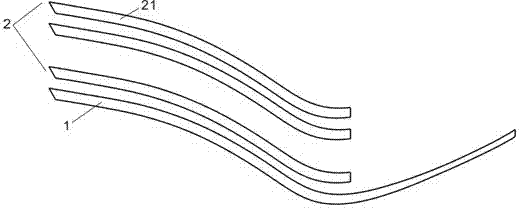

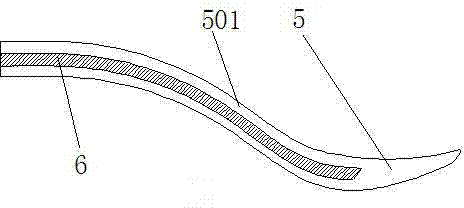

[0027] A method for manufacturing a midsole of a shoe, comprising the following steps: step 1, stirring a resin mixture, mixing the resin with a curing agent in a container; step 2, impregnating glass fiber cloth: The stirred resin mixture in step 1 is impregnated on the glass fiber cloth; step 3, cutting the glass fiber cloth, cutting the glass fiber cloth pre-impregnated in the step 2 according to the preset half-inserted midsole or midsole shape for later use. Step 4, hot press molding, put the glass fiber cloth cut out in the step 3 into the preheated mold, heat press the glass fiber cloth cut out in the step 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com