Intelligent mold

A mold and intelligent technology, applied in the field of extrusion molds, can solve the problems of wasting raw materials and spending a lot of debugging time, and achieve the effect of saving time, avoiding deviation and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

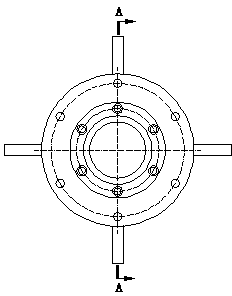

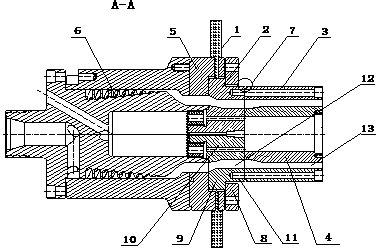

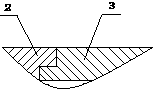

[0028] Such as figure 1 As shown, a kind of intelligent mould, comprises the die head 5 that coaxial center is arranged, mouth die 3 and first mold core 4, and described first mold core 4 and mouth die 3 form first runner 13, and described die head 5 There are four canbus bus magnetic displacement sensors 1 installed on it, and an eccentric adjustment mechanism 2 for adjusting the eccentricity of the die 3 and connected to the die 3 is installed in the die head 5. The eccentric adjustment mechanism 2 is connected to the bus magnetic displacement The sensor 1 is connected, and the eccentric adjustment mechanism 2 also forms a second flow channel 12 with the second mold core 10 arranged in the mould.

[0029] The eccentric adjustment mechanism 2 fixes the axial position of its detection part 9 and the die head 5 through the screw connection of the locking block 8, the eccentric adjustment mechanism 2 is connected with the canbus bus magnetic sensor 1 through its detection part 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com