Oil pump test system and its test method

A test system and test method technology, applied in the field of injection molding machines, can solve problems such as uneven quality, long test cycle, and inability to guarantee product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

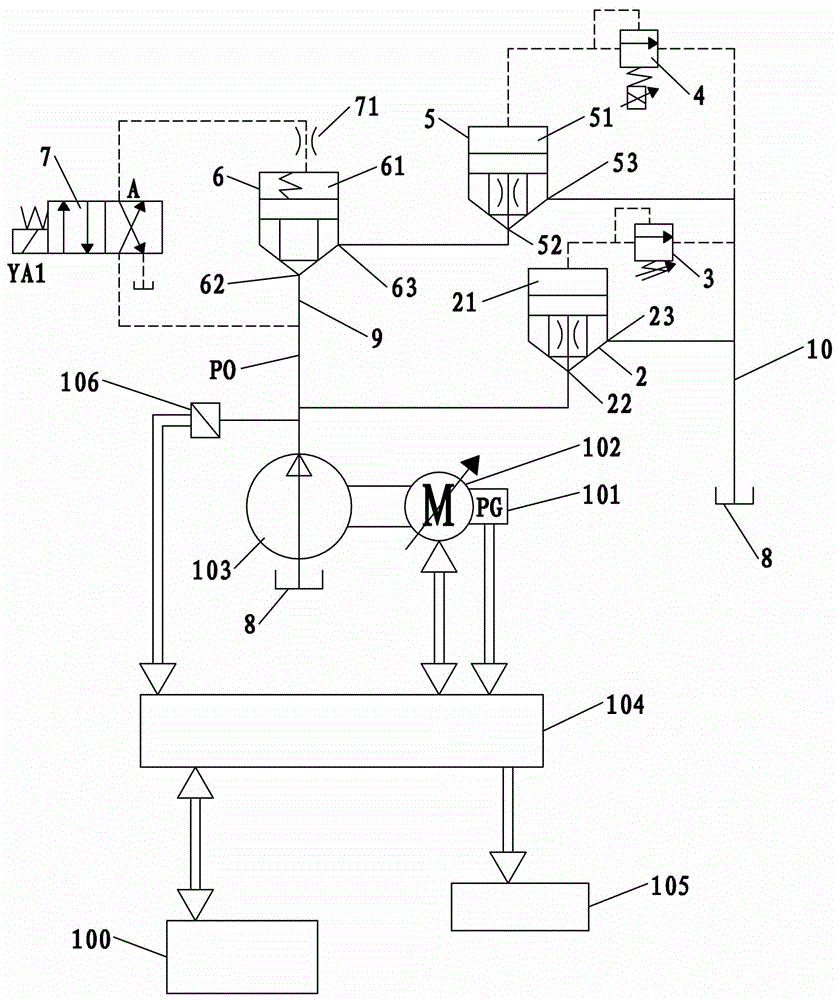

[0023] see figure 1 As shown, an oil pump test system includes a main controller 100, a servo motor 102 for driving the oil pump 103 under test, a servo control assembly for controlling the servo motor 102, a proportional relief valve 4, and a second relief valve 3 And the main oil circuit PO connected to the output port of the tested oil pump 103 is characterized in that it also includes a main test oil circuit for simulating the operation of the oil pump in the injection molding machine. The main test oil route is the cartridge valve A6 and the cartridge valve B5 , cartridge valve C2, directional valve 7, oil inlet pipeline 9 and oil return pipeline 10, cartridge valve A6 and cartridge valve B5 are connected in series between oil inlet pipeline 9 and oil return pipeline 10, and cartridge valve C2 is connected to Between the oil inlet pipeline 9 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com