Half honeycomb steel belt hobbing machine to ensure uniform forced convection flow field

A forced convection, honeycomb technology, applied in the direction of metal rolling, etc., can solve the problem that the semi-honeycomb steel strip cannot have a large arc twist, the semi-honeycomb steel strip has a large arc twist, and does not meet the requirements. Excessive extrusion and stretching of steel strips, solving large arc distortion, and good dimensional consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

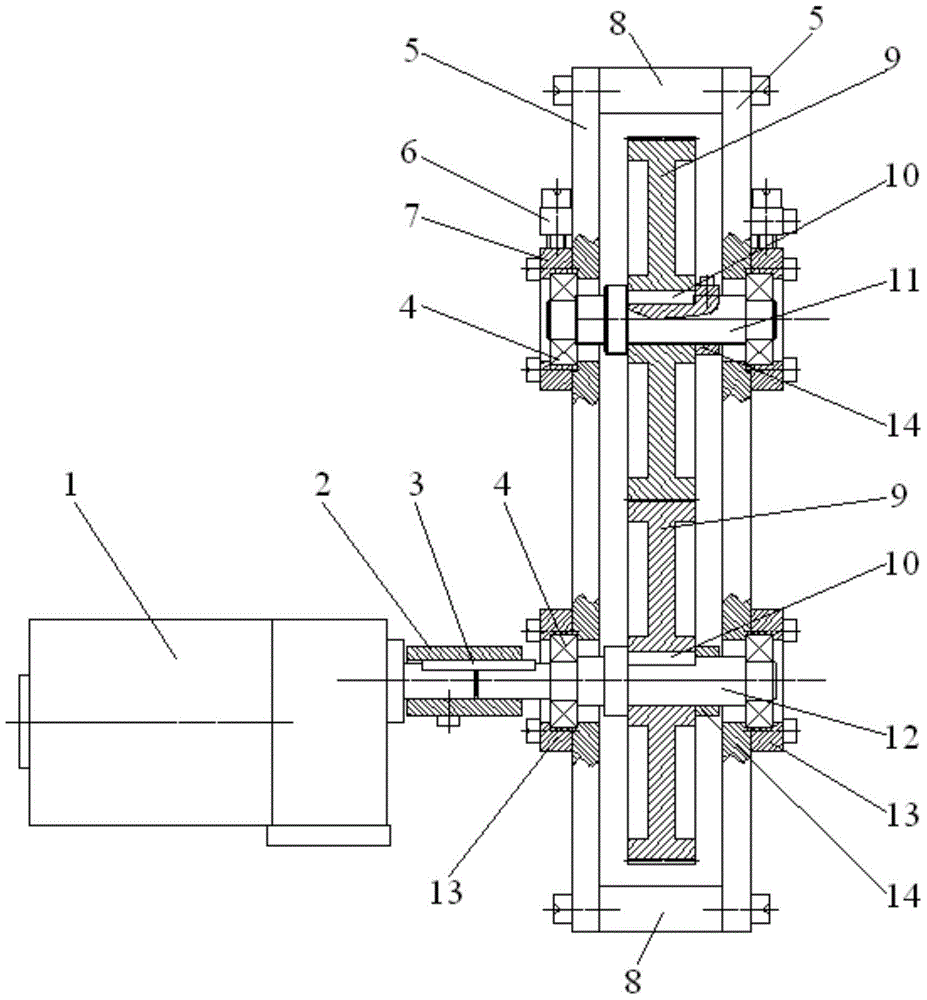

[0040] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0041] By analyzing the prior art, the inventive concept of the present invention is proposed:

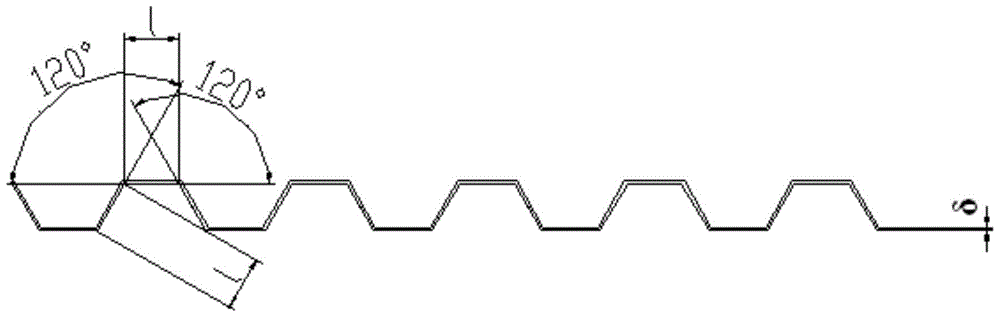

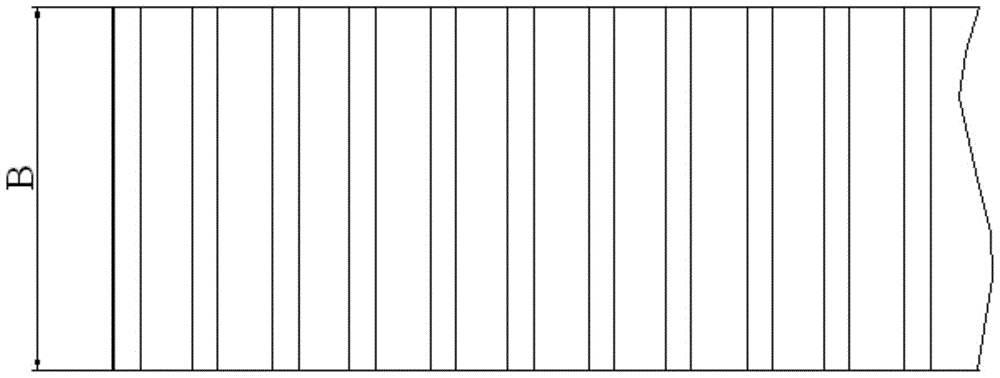

[0042] 1. Design new equipment using the principle of gear hobbing, and improve production efficiency under the premise of ensuring the dimensional accuracy of each side of the semi-hexagon;

[0043] 2. Design the fine-tuning mechanism of the driven gear shaft to solve the problem of slight changes in the thickness of the steel sheet and the large arc distortion of the semi-honeycomb steel belt;

[0044] 3. The slight error in the angle of the half hexagon can be resolved in the subsequent integer equipment.

[0045] Such as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com