A four-roll cross-rolling piercing machine

A cross-rolling piercing and piercing machine technology, which is applied in the direction of metal rolling, can solve the problems of slipping between the rolled piece and the roll, poor biting conditions, and difficult biting, and achieves good vibration damping performance, light weight, and convenient arrangement. The effect of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiment given below intends to further illustrate the present invention, but can not be interpreted as the restriction to protection scope of the present invention, those skilled in the art still belongs to the protection of the present invention to some non-essential improvements and adjustments of the present invention according to the content of the present invention scope.

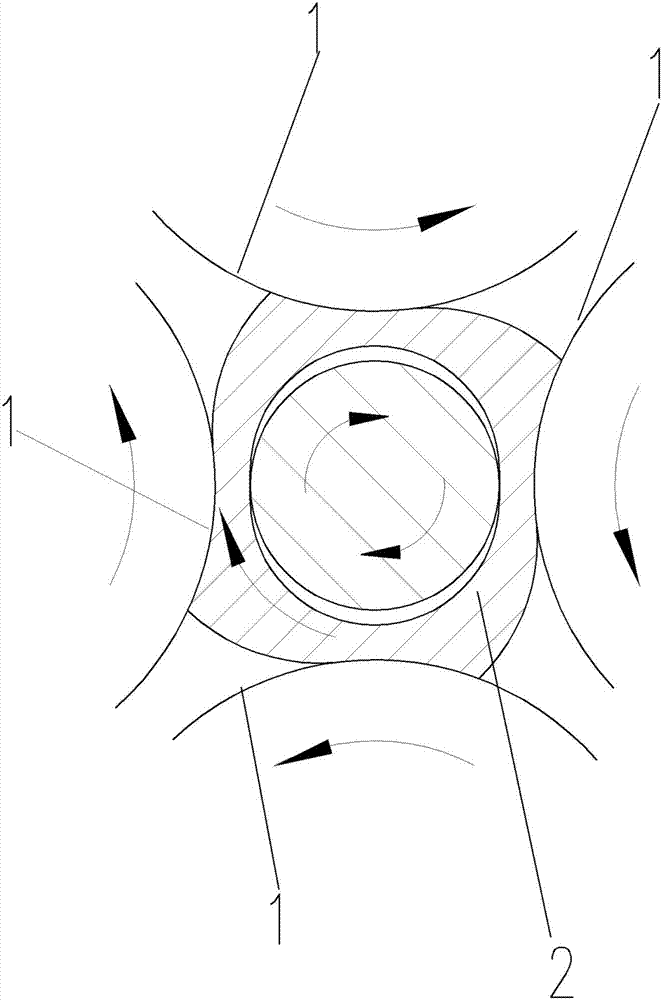

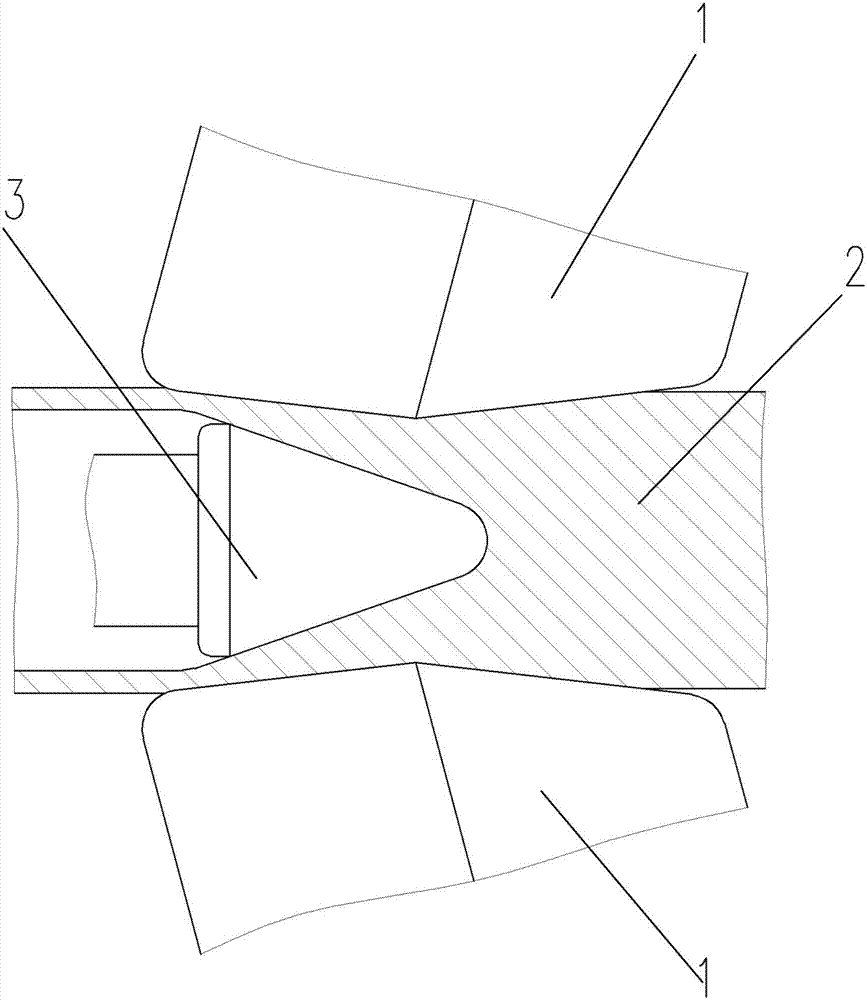

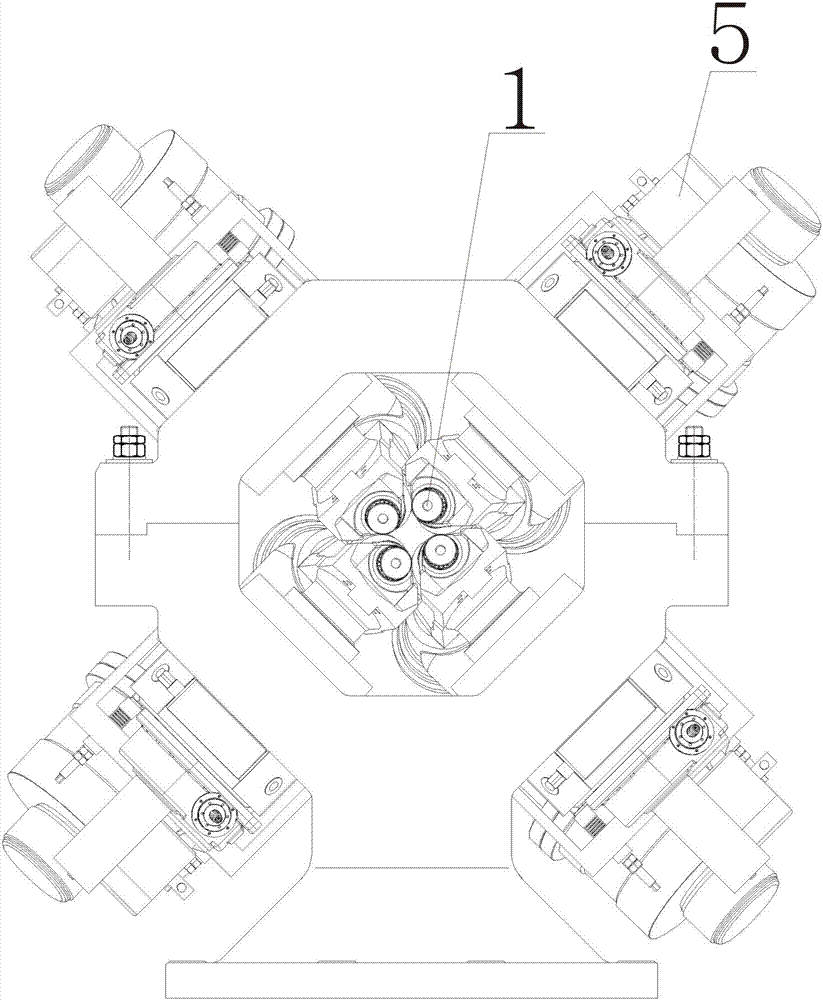

[0031] Four-roll cross-rolling piercing machine, such as figure 1 , figure 2 , image 3 , Figure 4shown. The four-roll cross-rolling piercer is arranged with four conical rolls 1, which are evenly distributed at 90° along the center of the workpiece 2; every two of the four conical rolls 1 form a pair of working cones. Shaped rolls 1; the distance ratio between the two pairs of tapered rolls 1 roll surface is 1.06-1.09, and the four tapered rolls 1 have their own independent driving power device; the rotation directions of the four tapered rolls 1 are the same. The four-roll rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com