Super-oleophobic and lyophobic coating and preparation method thereof

A technology of hydrophobic coating and processing method, which is applied in coatings, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of no industrial mass production, restrictions on industrial application, and difficulty in achieving oleophobicity, etc., to achieve Simple processing method, good self-cleaning performance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

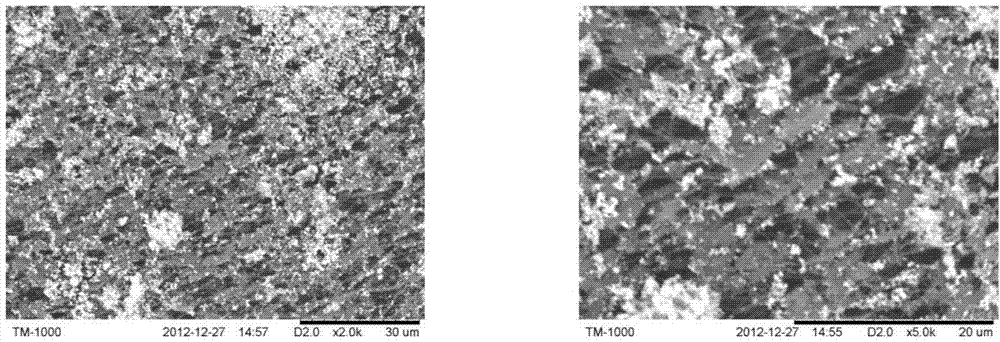

[0028] Prepare 0.1wt% ethylaminocatechol solution, soak the PTFE membrane silk in the solution for 3h, see figure 1 with figure 2 . After drying, use 50mM Cu(NO 3 ) 2 The solution and the 1wt% perfluoroalkyl phosphate solution were soaked for 1 hour respectively. The contact angle tester shows that the contact angle to kerosene is 75-80 degrees.

Embodiment 2

[0030] A 0.2wt% ethylaminocatechol solution was prepared, and the PTFE substrate was soaked in the solution for 1.5h. After drying, use 50mM AgNO 3 The solution and the 1wt% perfluorooctyl quaternary ammonium iodide solution were each soaked for 2 hours. The contact angle tester shows that the contact angle to kerosene is 110-120 degrees.

[0031] Figure 5 It shows the contact angle of the treated PTFE hollow fiber membrane for water, kerosene, and alcohol. PTFE itself can be strongly hydrophobic, but it will be infiltrated when it encounters alcohol and kerosene. It can be clearly found in the figure that PTFE has obtained oleophobic properties after being coated.

Embodiment 3

[0033] A 0.1 wt% ethylaminocatechol solution was prepared, and an A4 paper substrate was soaked in the solution for 2 hours. After drying, use 50mM AgNO 3 The solution and the 1wt% perfluoroalkyl betaine solution were soaked for 1 hour respectively. The contact angle tester shows that the contact angle to kerosene is 85-90 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com