Automatic winding machine of soybean gluten

A rolling machine and automatic technology, applied in the direction of dairy products, cheese substitutes, applications, etc., can solve the problems of unreasonable structural design of rolling roller conveying device, increase energy consumption of electrical equipment, affect the production efficiency of soybean gluten, etc., and achieve improvement Energy-saving effect, structure simplification, and production efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with accompanying drawing:

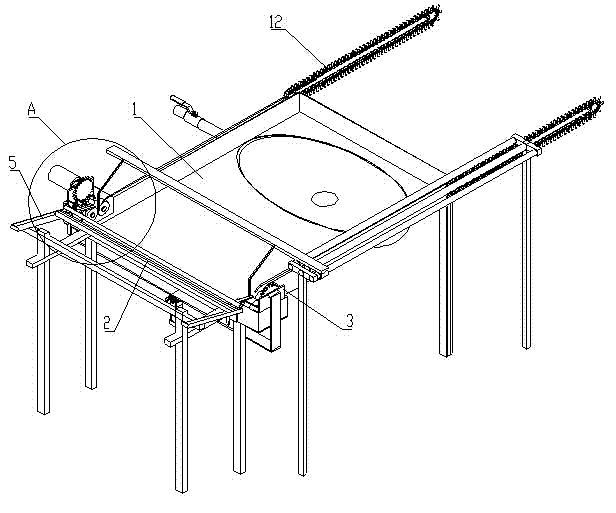

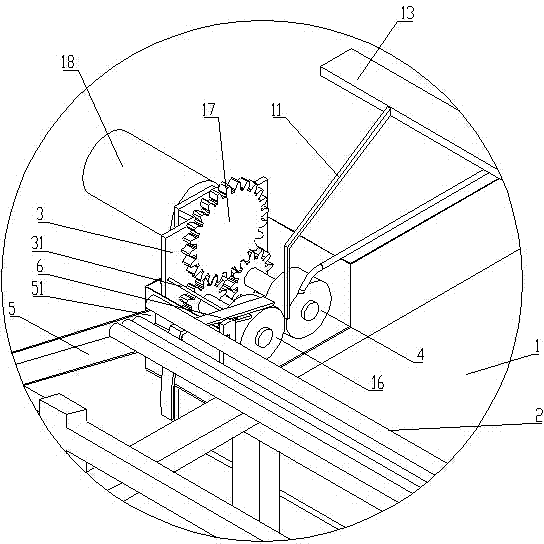

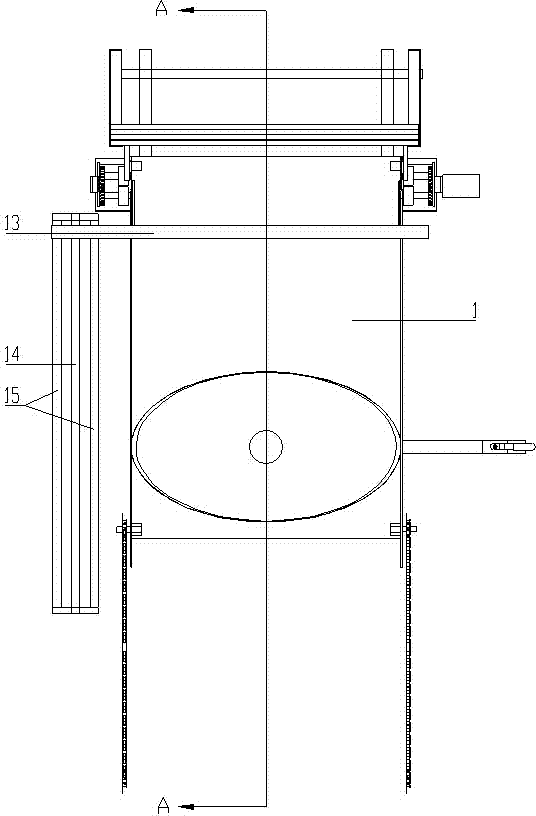

[0028] Such as Figure 1-6 As shown, the bean stick automatic rolling machine in this embodiment includes a bean gluten pot 1, a roll drive device installed on the bean gluten pot 1 for driving the roll 2 to rotate around its own axis, and a roll drive device for driving the roll 2 to rotate around its own axis. Roller lifting device that reciprocates up and down as a whole. The roll driving device includes a support 3 and a wheel A4 arranged on the support 3 for driving the roll to rotate. The roll driving device also includes a wheel B16, Wheel C17 and drive motor 18, described wheel A4 and wheel B16 are clamped and cooperated to rub roll roll 2 to rotate around its own axis, and described wheel C17 is connected with wheel A4 and wheel B16 transmission respectively, and described wheel C17 is driven by drive motor 18 to drive and rotate, the roller driving device is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com