Yak Triton production method suitable for pastoral area

A production method and qula technology, applied in dairy products, climate change adaptation, cheese substitutes, etc., to achieve the effects of stable quality, good color and flavor, fast fermentation and drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (4) Pick up the coagulum obtained from the fermentation in step (3), put it into a stainless steel mesh tray with a 40-mesh filter cloth, cover and drain for 30 minutes, and there will be no dripping;

[0047] (5) Disperse the drained coagulum into small particles of 0.5-1cm, spread evenly on a tray with a stainless steel sieve bottom, place the tray in a solar drying room, adjust the ventilation valve, and control the temperature of the drying room at 45°C , under the condition of wind speed 0.1m / s, the drying was completed in 14 hours, and finally 4.25 kg of Qula was obtained;

[0048] (6) Put the dried Qula into a light-proof bag, seal it and store it in a dry and cool place.

[0049] Example 2

[0050] (1) Fresh milk collection: Collect 50 kg of fresh yak milk and filter it with 4 layers of gauze;

[0051] (2) Centrifugal degreasing: heat the filtered yak milk in a water bath to 50°C, use an electric cream separator at a speed of 4300r / min to degrease, and put the...

Embodiment 2

[0053] (4) Pick up the coagulum obtained from fermentation in step (3), put it into a stainless steel mesh tray with a 20-mesh filter cloth, cover and drain until no water drips;

[0054] (5) Disperse the drained coagulum into small particles of 0.5-1cm, spread evenly on a tray with a stainless steel sieve bottom, place the tray in a solar drying room, adjust the ventilation valve, and control the temperature of the drying room at 55°C , under the condition of wind speed 0.5m / s, finish drying after 10h, and obtain 4.95 kilograms of Qula;

[0055] (6) Put the dried Qula into a light-proof bag, seal it and store it in a dry and cool place.

[0056] Example 3:

[0057] (1) Fresh milk collection: Collect 50 kg of fresh yak milk and filter it with 4 layers of gauze;

[0058] (2) Centrifugal degreasing: heat the filtered yak milk in a water bath to 45°C, use an electric cream separator to degrease at a speed of 4600r / min, and put the skim milk into a stainless steel bucket;

Embodiment 3

[0060] (4) Pick up the coagulum obtained from fermentation in step (3), put it into a stainless steel mesh tray with a 60-mesh filter cloth, cover it and drain until there is no water dripping;

[0061] (5) Disperse the drained coagulum into small particles of 0.5-1cm, spread evenly on a tray with a stainless steel sieve bottom, place the tray in a solar drying room, adjust the ventilation valve, and control the temperature of the drying room at 65°C , when dried for 7.5 hours under the condition of wind speed 0.3m / s, the inside and outside of the product were dry and hard, crisp and delicious when chewed, and finally 4.82 kg of Qula was obtained;

[0062] (6) Put the dried Qula into a light-proof bag, seal it and store it in a dry and cool place.

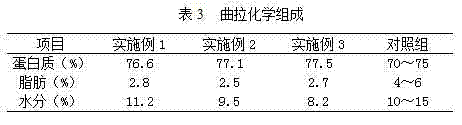

[0063] The quality of the yak qula made by this method is evaluated, and the results are as follows:

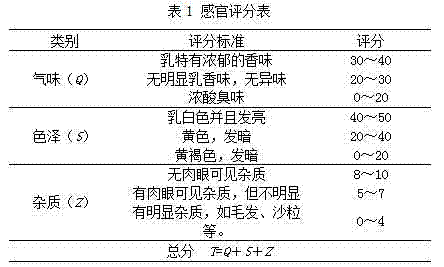

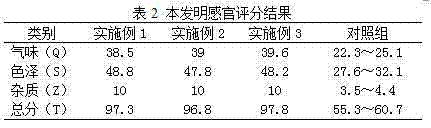

[0064] (1) Sensory evaluation

[0065] The sensory evaluation of yak Qula was carried out by using the method of sensory scori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com