Corn ear multi-roll thresher based on dispersing and then threshing

A technology of corn ears and threshers, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as easy to break, easy to mold, and insects, so as to reduce the interaction force, reduce the threshing force, and avoid broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

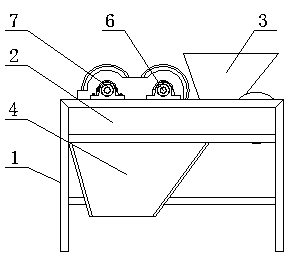

[0018] Corn ear multi-roller thresher based on first discretization and then threshing, such as figure 1 As shown, the threshing machine comprises a frame 1, a motor fixed on the frame 1 and a threshing chamber 2, a hopper 3 arranged at the top of the input end of the threshing chamber 2 and a receiving hopper 4 arranged at the bottom of the threshing chamber 2, for making The ear of corn can move actively, and the threshing chamber 2 is set in an inclined manner, that is, the vertical height of the input end of the threshing chamber 2 is higher than that of the output end.

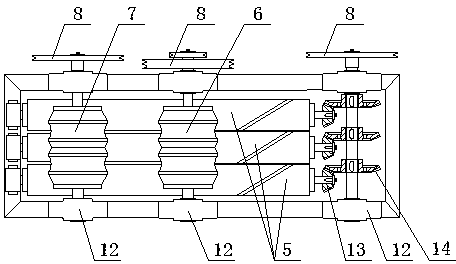

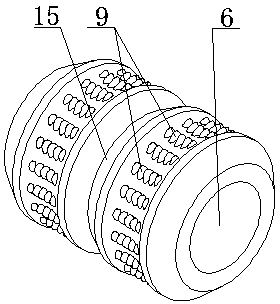

[0019] Such as figure 2 The shown threshing chamber 2 is provided with a plurality of differential speed rollers 5 extending from its input end to the output end, and the output end of the threshing chamber 2 corresponds to the end of the differential speed roller 5. A cob outlet for the threshed corncobs to be discharged is provided. At the top of the differential speed roller 5, there are discrete rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com