Mechanical type dual-cavity seeding apparatus

A kind of seed metering and mechanical technology, applied in the direction of planter parts, etc., can solve the problems of high seed damage rate, seed filling, seed protection, difficulty in clearing seed, and poor effect, so as to achieve less seed hoarding and improve seed metering stability. The effect of increasing the volume of the seed cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

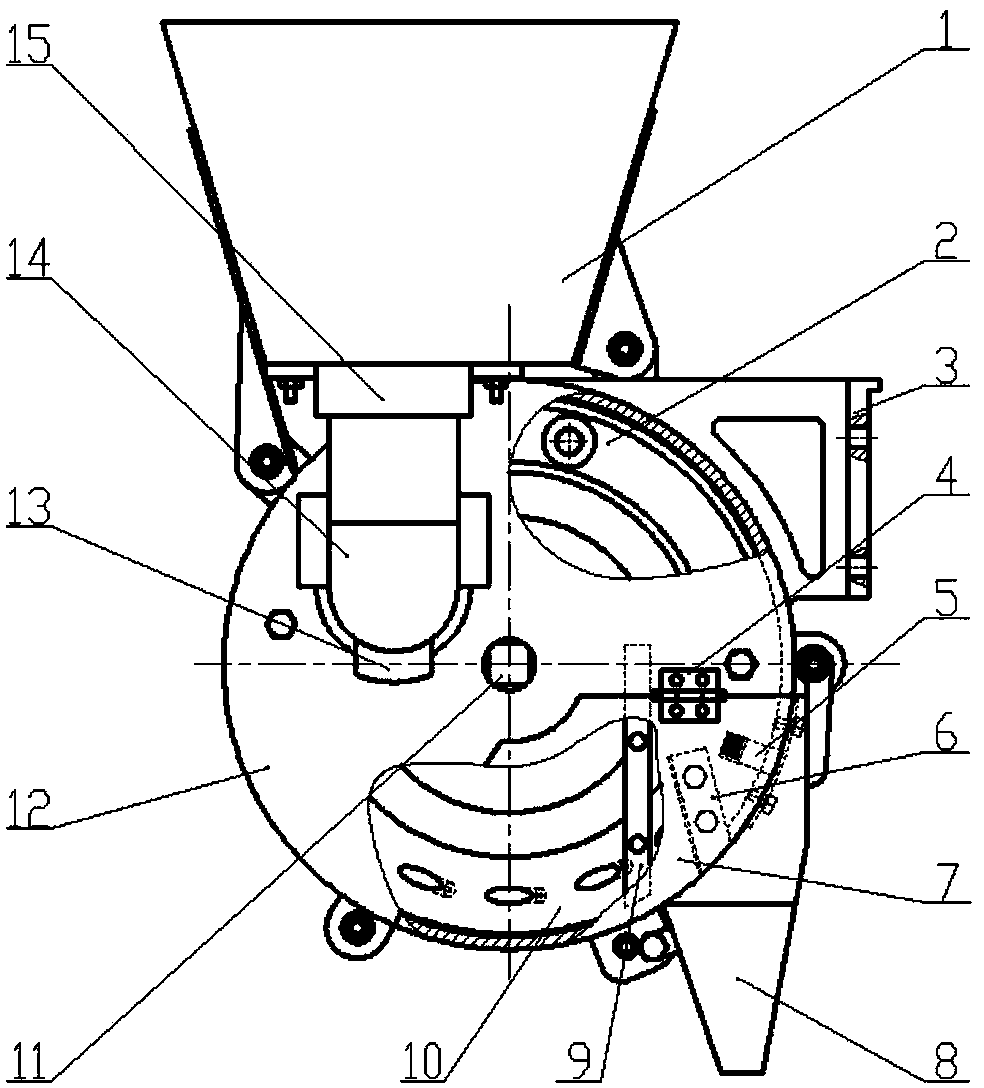

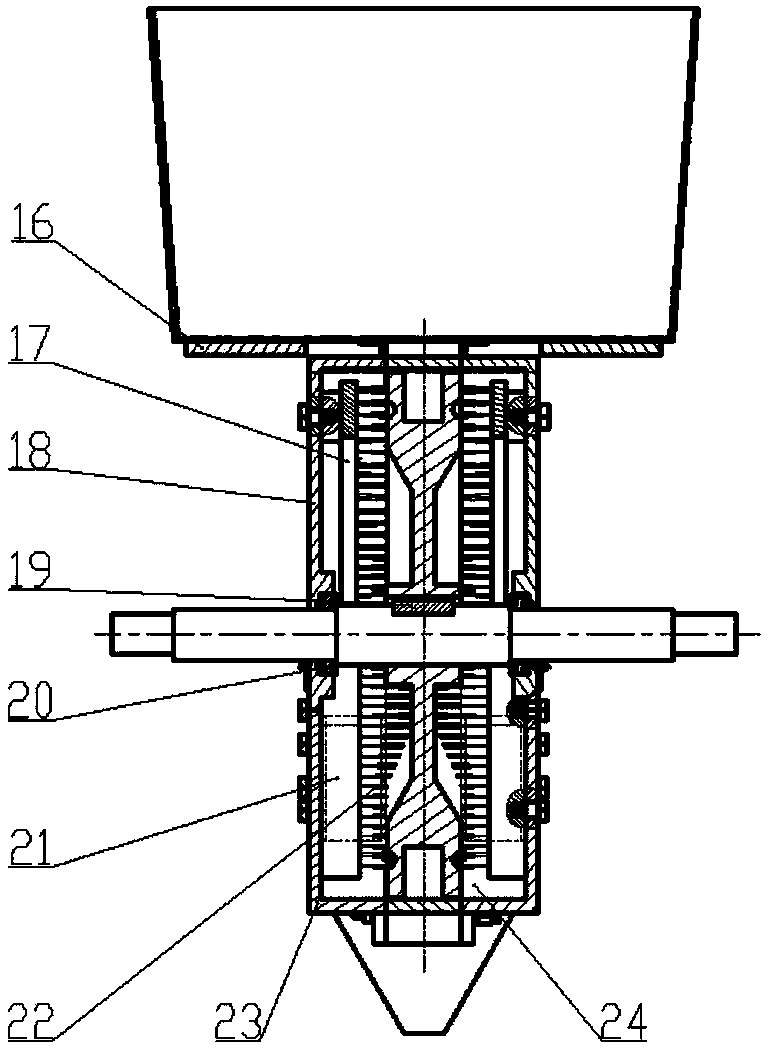

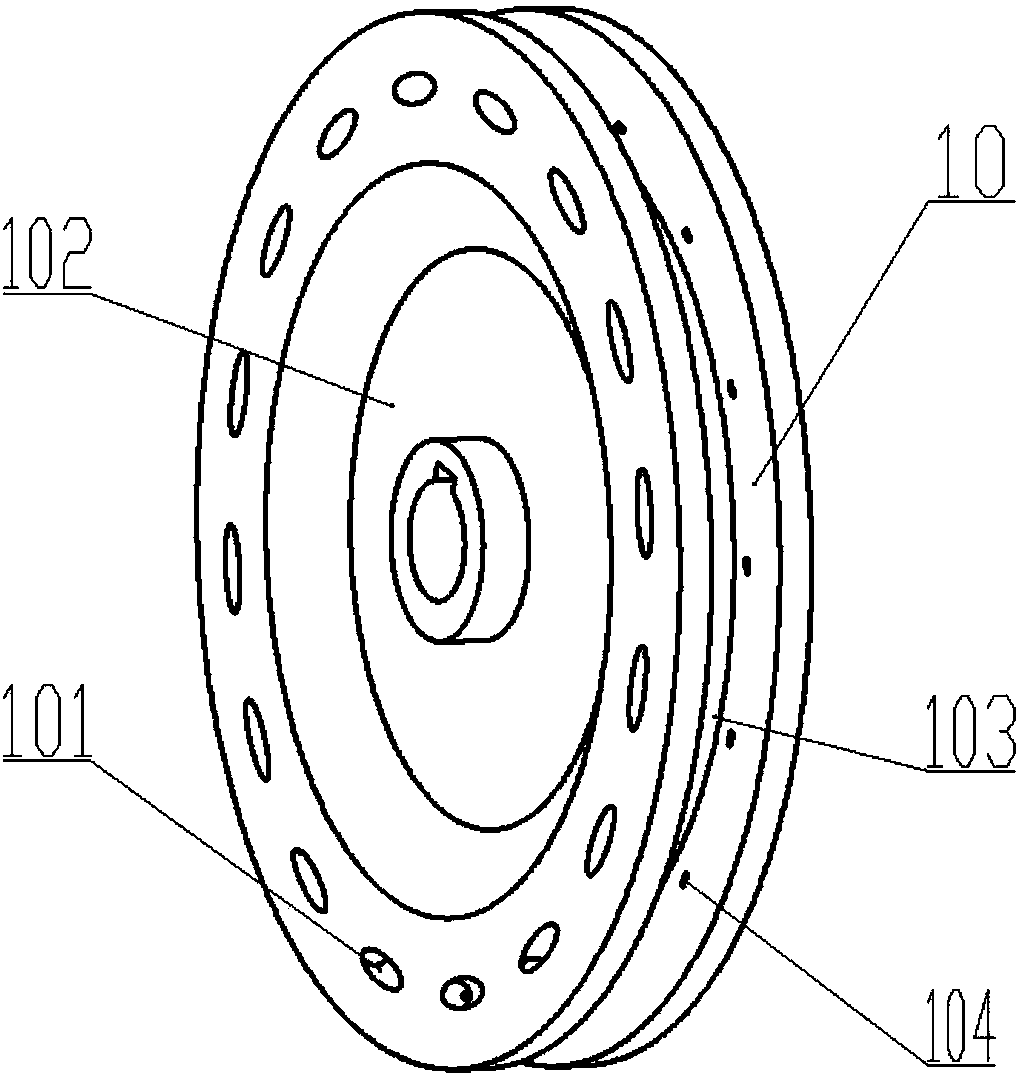

[0044] Such as figure 1 and figure 2 As shown, a kind of double-cavity mechanical seed metering device of the present invention is left and right symmetrical, and on the left and right housings 18 and 12 of the seed metering device, left and right arc-shaped seed clearing and protecting plates 17 and 22 are fixed by bolts And left and right every kind of hairbrush 21 and 9, every kind of hairbrush separates the filling district in the filling chamber 24 with the district of throwing seeds. Seeds enter the hole 101 in the seed filling area with the disturbance of the seeding disc 10, and then enter the seed clearing and protecting area. The seeding area completes the seeding process.

[0045] A double-cavity mechanical seed metering device, comprising a seed box 1, a right arc-shaped seed clearing and protecting plate 2, a left arc-shaped seed clearing and protecting plate 17, an intermediate housing 3, a right-turning seed unloading cover 7, a left-turning Type unloading c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com