Composite article and methods therefor

一种复合制品、复合结构的技术,应用在化学仪器和方法、分层产品、机器/发动机等方向,能够解决交错的程度受限、设计选项限制、结果硬度和强度不容易优化等问题,达到增强接合部强度、增加重量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

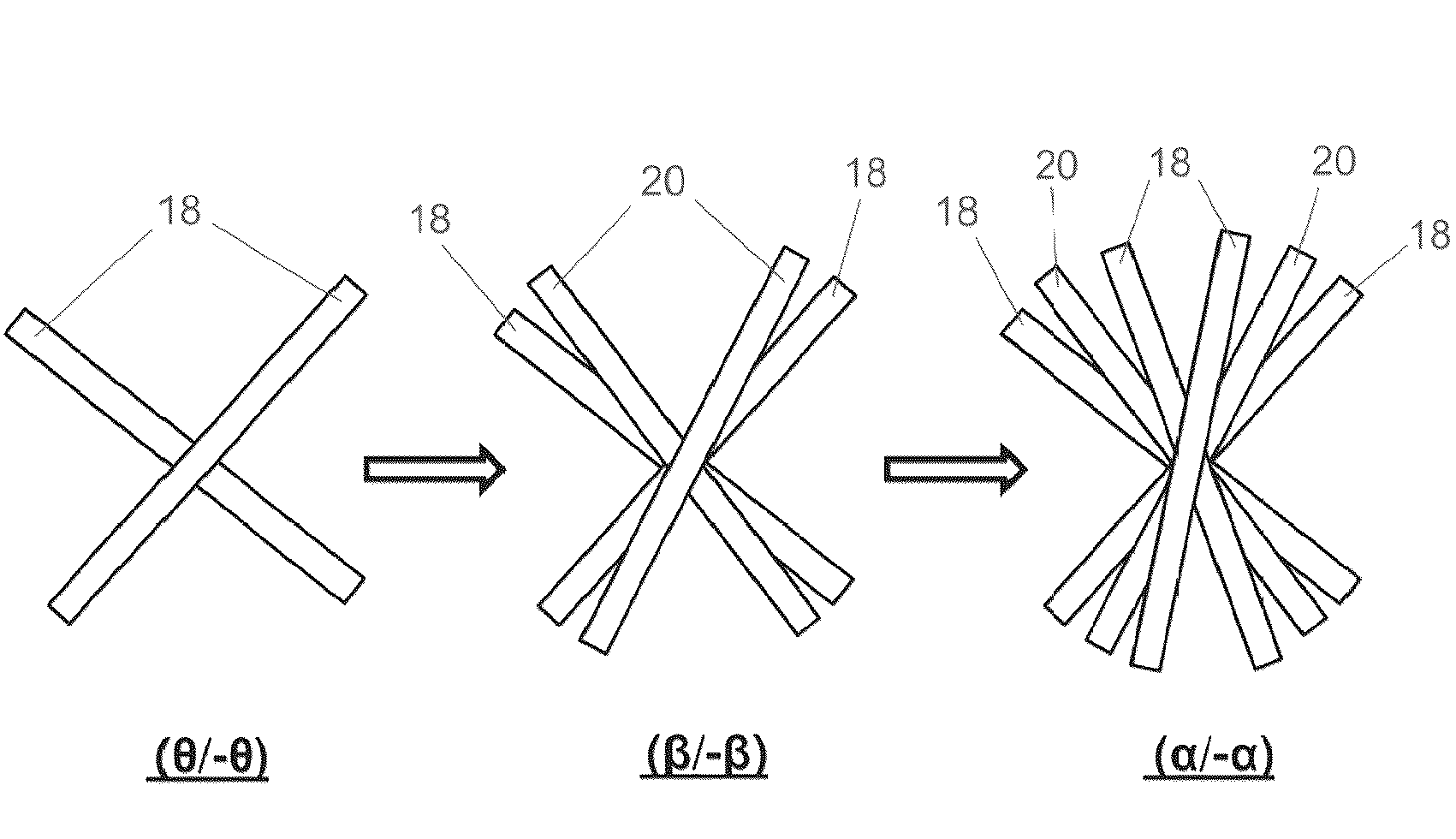

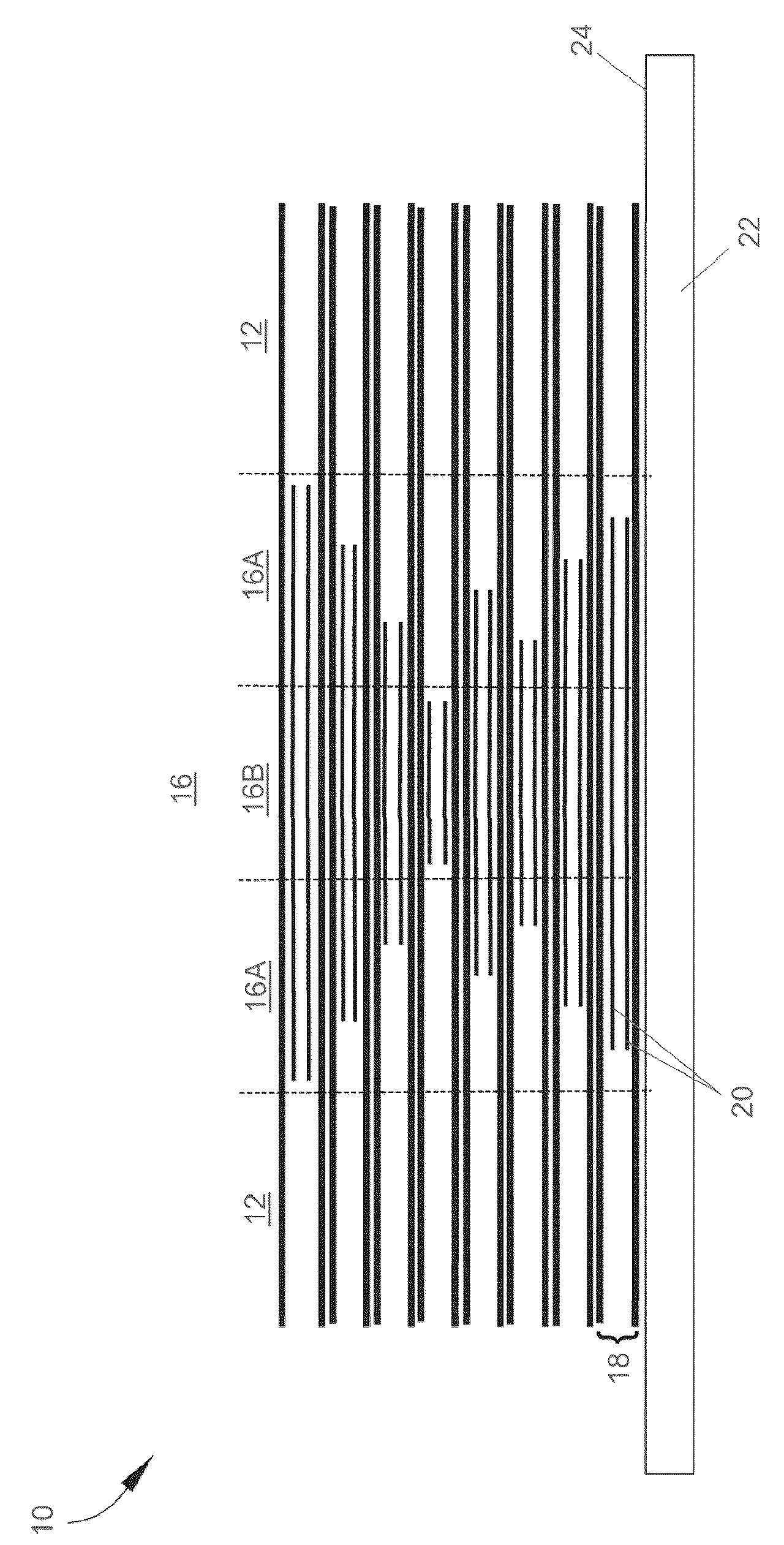

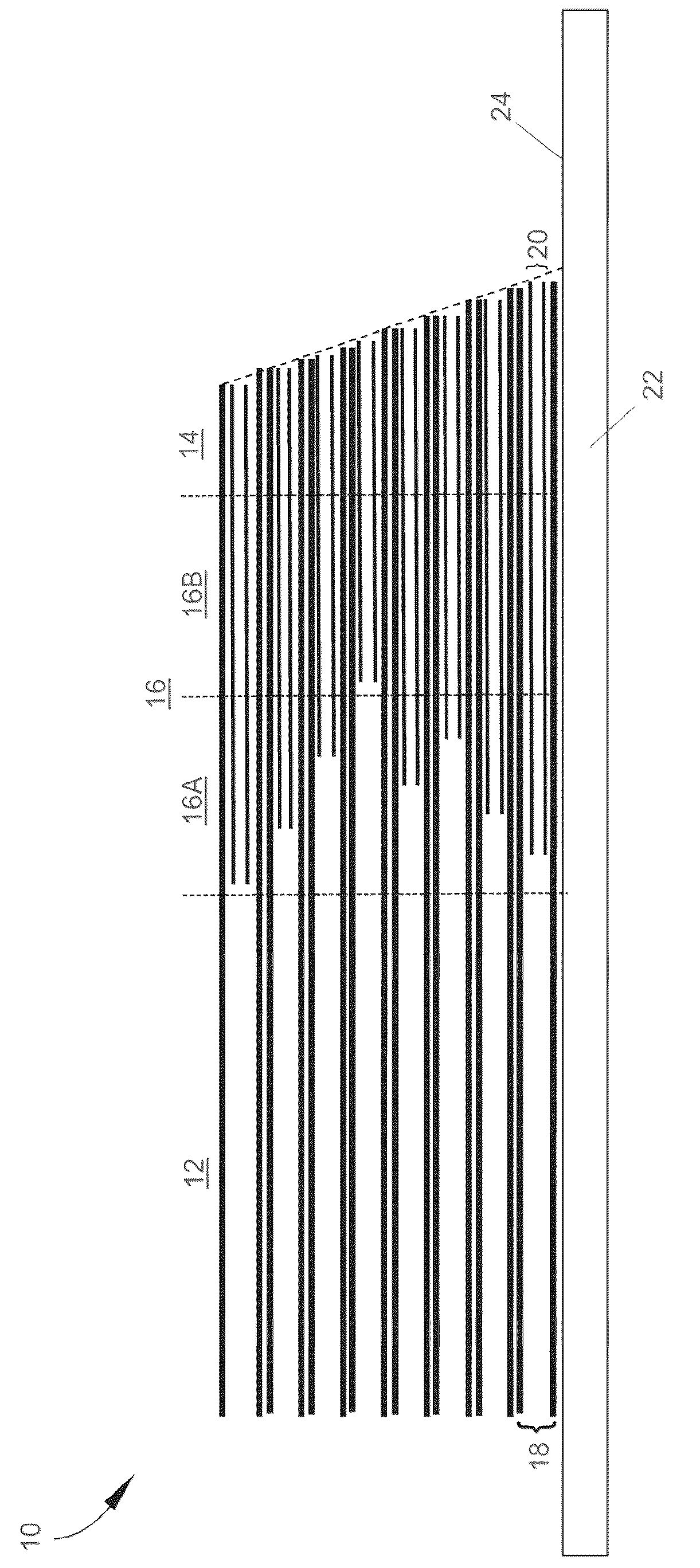

[0017] The present invention will be described with respect to a process for producing a composite article, which is formed from a fiber-reinforced laminate material to include a primary composite structure that incorporates at least one integral secondary composite structure. The secondary composite structure extends from the plane defined by the continuous reinforcing material within the primary composite structure. Although various applications are foreseeable and possible, applications of particular interest include applications that require relatively lightweight components, such as gas turbine components, including aircraft gas turbine engines. Of particular interest are composite articles with integral composite flanges, such as fan housings for aircraft gas turbine engines. Other possible secondary structures may include, but are not limited to, integral reinforcement rings and structural partitions on the shell structure.

[0018] Although the teachings of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com