Measuring method for microscopic height of thread of end seal of workpiece

A technology of height measurement and measurement method, applied in the field of measurement, can solve the problems of increased production cost, difficulty in inspection operation level, inconvenience, etc., and achieve the effect of low cost and flexible measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

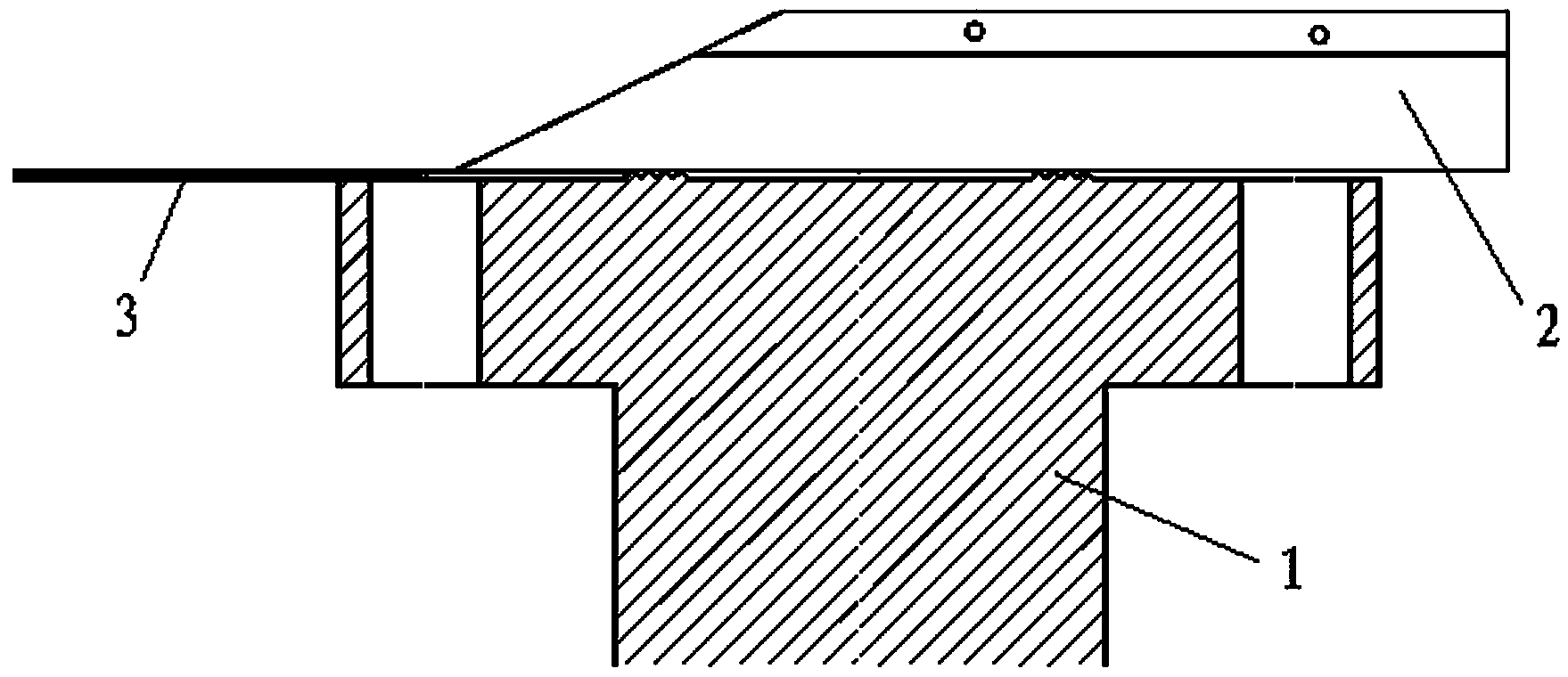

[0012] The invention discloses a method for measuring the microcosmic height of a tooth profile of a sealing mouth of a workpiece. The measuring method adopts a commercially available feeler gauge 3 and a knife-edge ruler 2 to complete the measurement. The method for measuring the microcosmic height of the tooth form of the sealing port of the workpiece comprises the following steps:

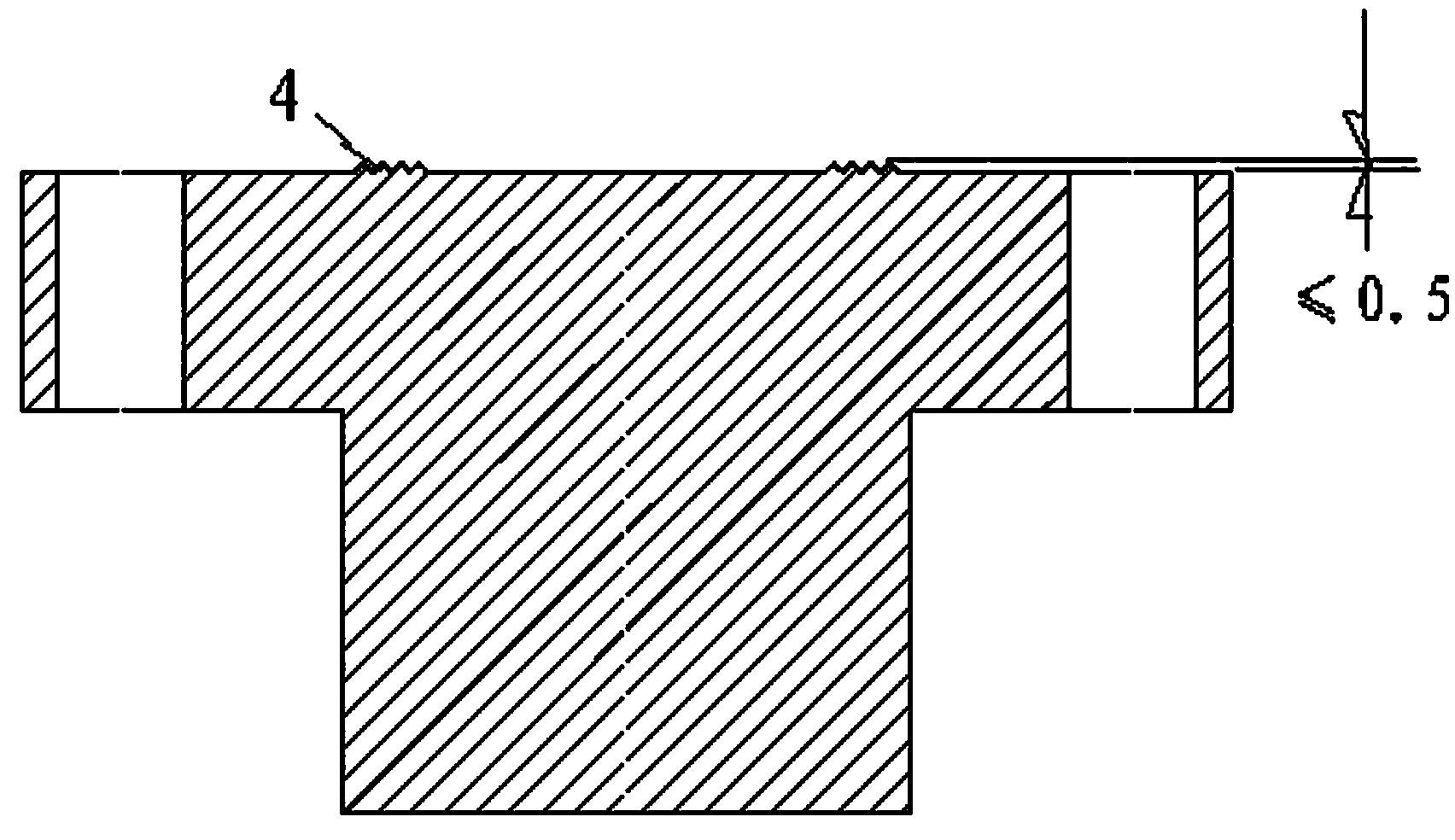

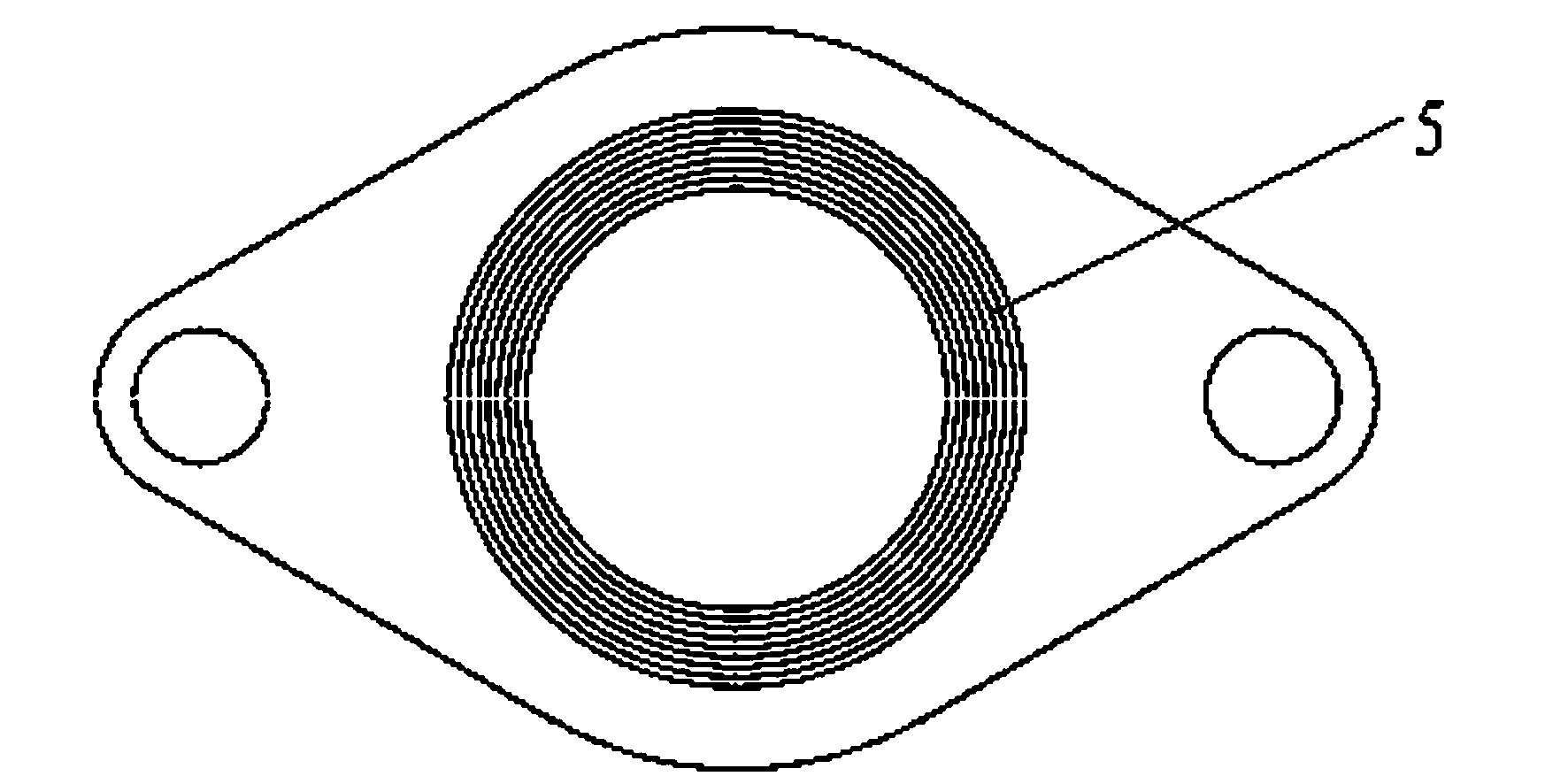

[0013] A. Use the knife-edge ruler 2 to measure the length of any chord of the concentric circle 5 of the tooth profile of the sealing port of the workpiece 1. The extension part forms a gap with the sealing surface of the workpiece 1.

[0014] B. Fill the gap with one or several pieces of known thickness in the feeler gauge 3, and calculate the nominal value of the known thickness to be the actual measurement size of the microcosmic height of the concentric circle tooth type 4.

[0015] Knife-edge ruler and feeler gauge are general measuring tools with flexible measuring methods, see figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com