oscillating power tool

A technology for oscillating power tools and output shafts, which is applied in the direction of manufacturing tools, portable motorized devices, and non-rotating vibration suppression. It can solve problems such as large vibrations, harmful to user's hand health, and unfavorable use, so as to reduce vibration and improve vibration numbness. Hand problems, the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred implementation of the oscillating power tool will be described below with reference to the accompanying drawings.

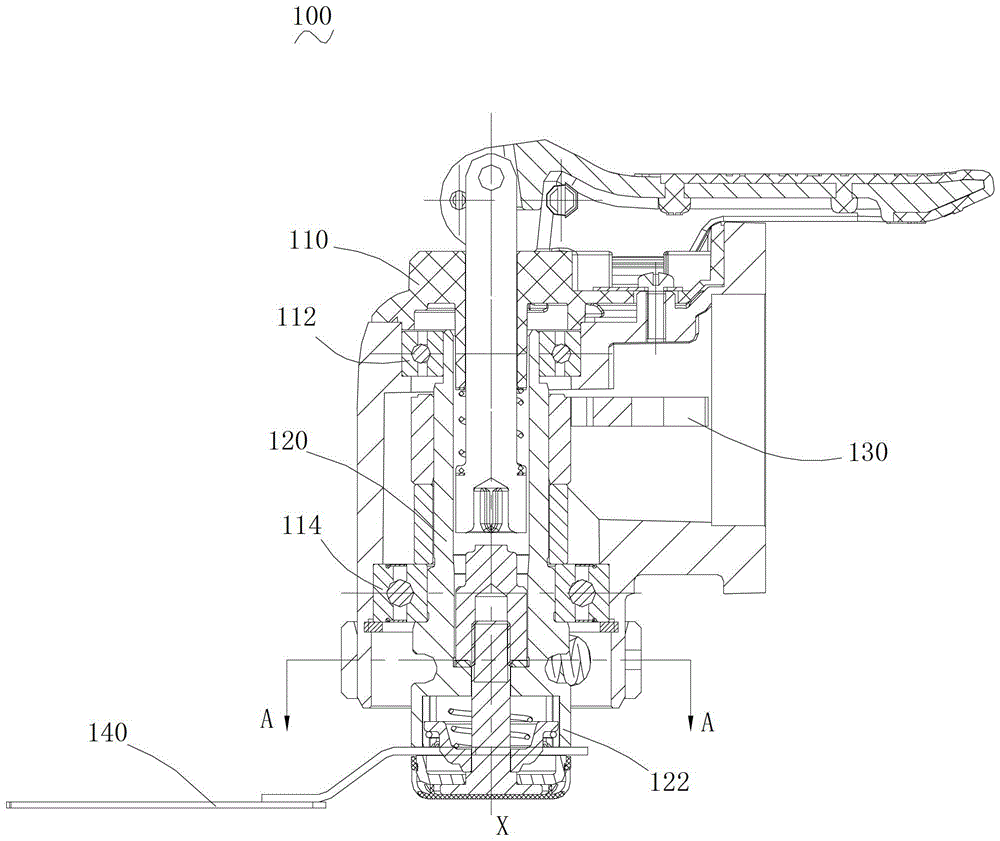

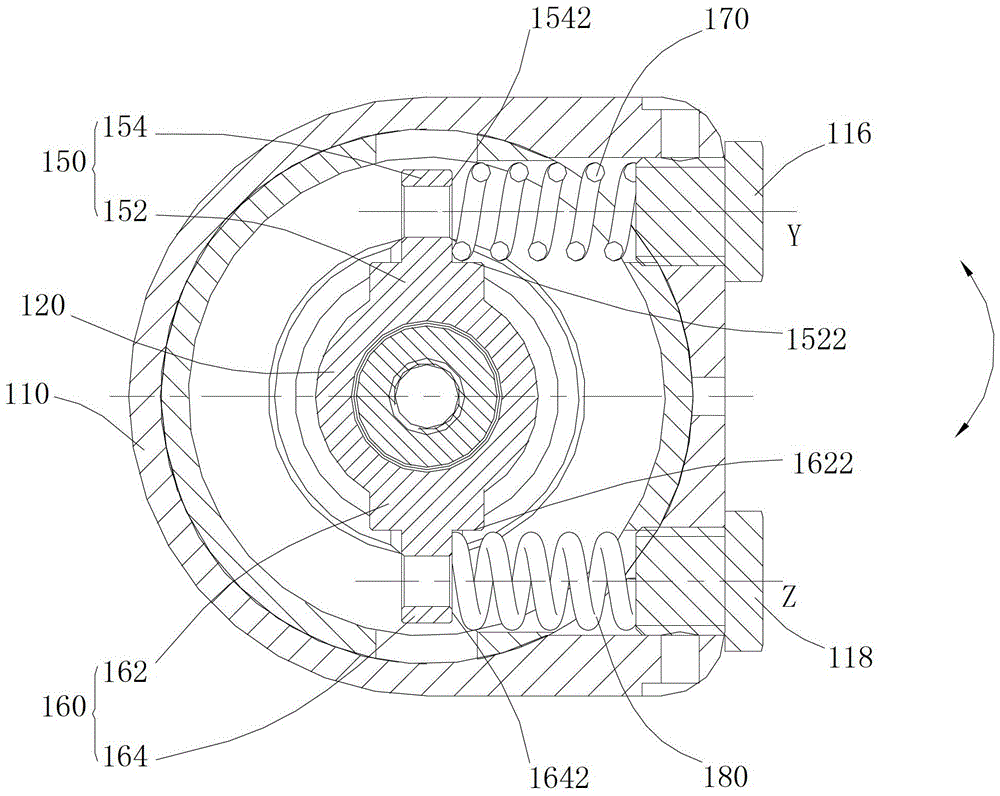

[0029] Please refer to figure 1 , an oscillating power tool 100 , that is, a multifunctional machine, includes a head shell 110 , an output shaft 120 extending in the head shell 110 , and a shift fork 130 fixedly connected to the output shaft 120 at one end. The output shaft 120 is capable of swinging motion around its own axis X. The oscillating motion of the output shaft 120 adopts the usual method of oscillating tools, that is, the fork 130 is connected to the eccentric wheel, and the eccentric wheel is connected to the drive shaft of the motor, so that the rotational motion of the drive shaft of the motor is converted into the rotation of the output shaft 120. swinging motion. In this way, when different attachment heads are connected to the output shaft 120, such as straight saw blades, circular saw blades, triangular grinding discs, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com