Adhesive composition with excellent barrier properties

A technology of composition and binder, applied in the direction of adhesives, nonlinear optics, input/output process of data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

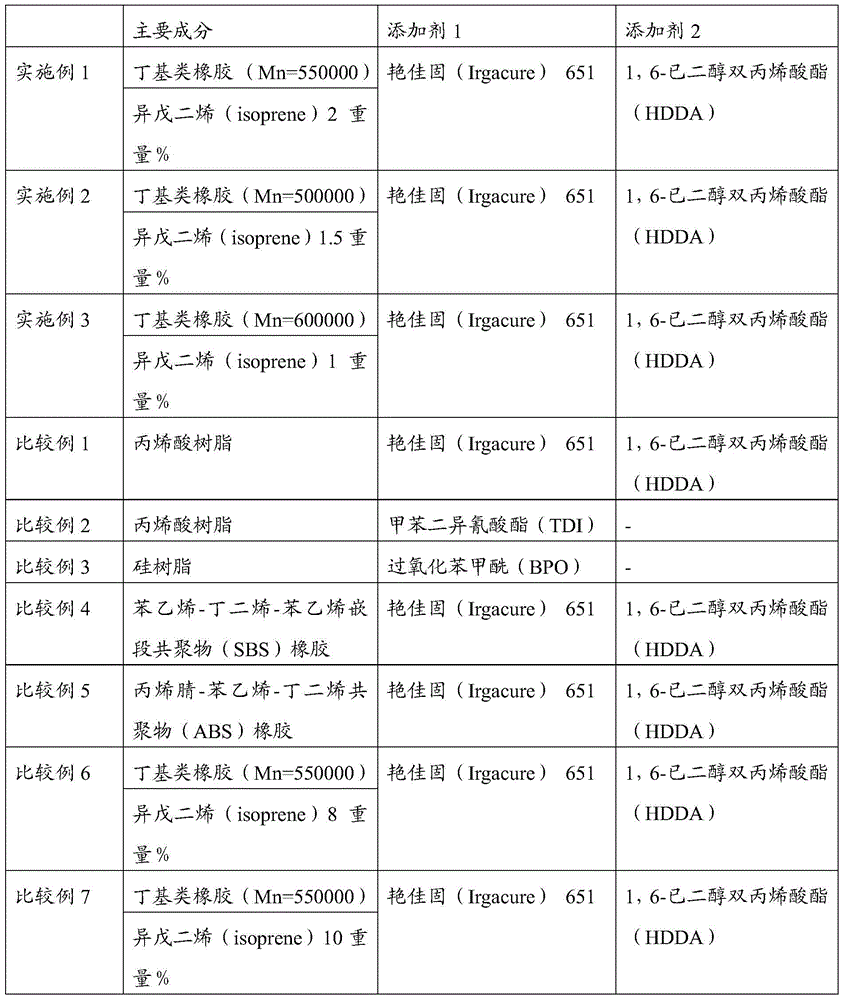

Image

Examples

experiment example

[0049] Experimental Example - Determination of Moisture Permeability and Peeling Force of Adhesive Composition

[0050] The adhesive composition of the above-mentioned embodiment and comparative example is cured by the method described in the following table 2, and then after the width is 1 inch and the length is 10 cm, after cutting, use a 2 kg roller on one side of the polycarbonate to carry out 5 30 minutes later, the peeling force was measured with a universal testing machine at a peeling speed of 300 mm / min. And, the thickness of the cured adhesive was 50 μm to form an adhesive layer, and the water vapor transmission rate (WVTR) was measured with a water vapor transmission meter Labthink, TSY-T3.

[0051] Table 2

[0052]

curing method

Moisture permeability (g / m 2 day)

Peel force(g / in)

Example 1

Thermal curing + Ultraviolet (UV) curing

5.2

1100

Example 2

Thermal curing + Ultraviolet (UV) curing

4.7

1300

Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com