Hollow Fiber Membrane Module

A technology of fiber membranes and fiber membrane bundles, which is applied in the field of hollow fiber membrane modules, can solve the problems of uncontrollability and low productivity, and achieve the effects of excellent liquid tightness, efficient manufacturing, and high joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

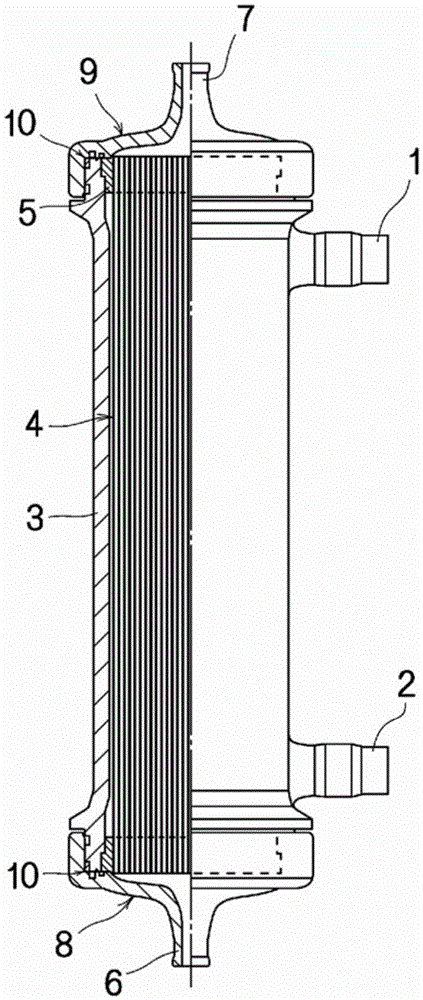

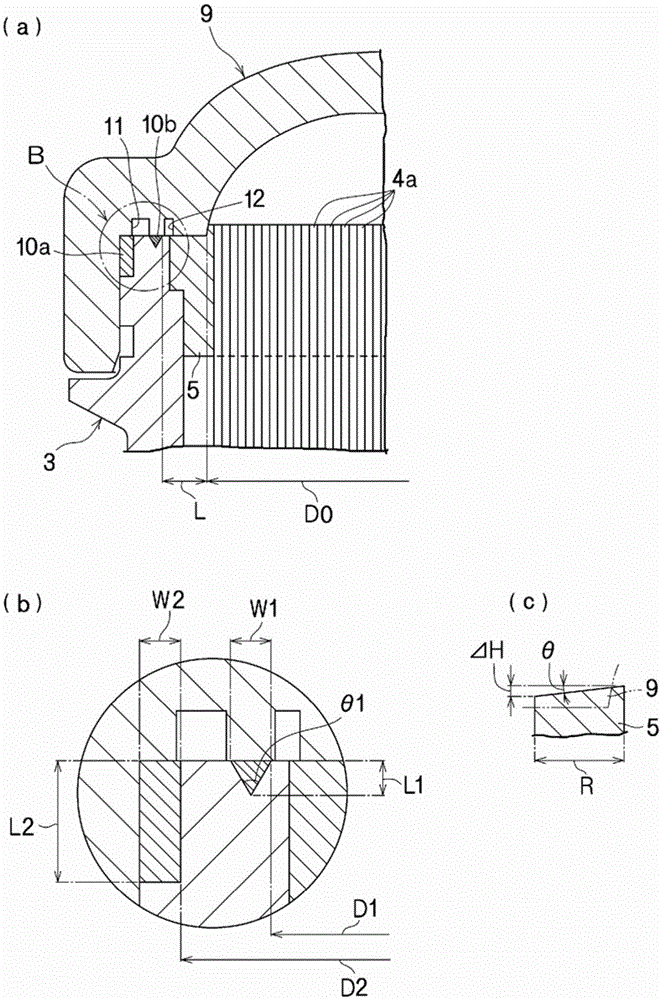

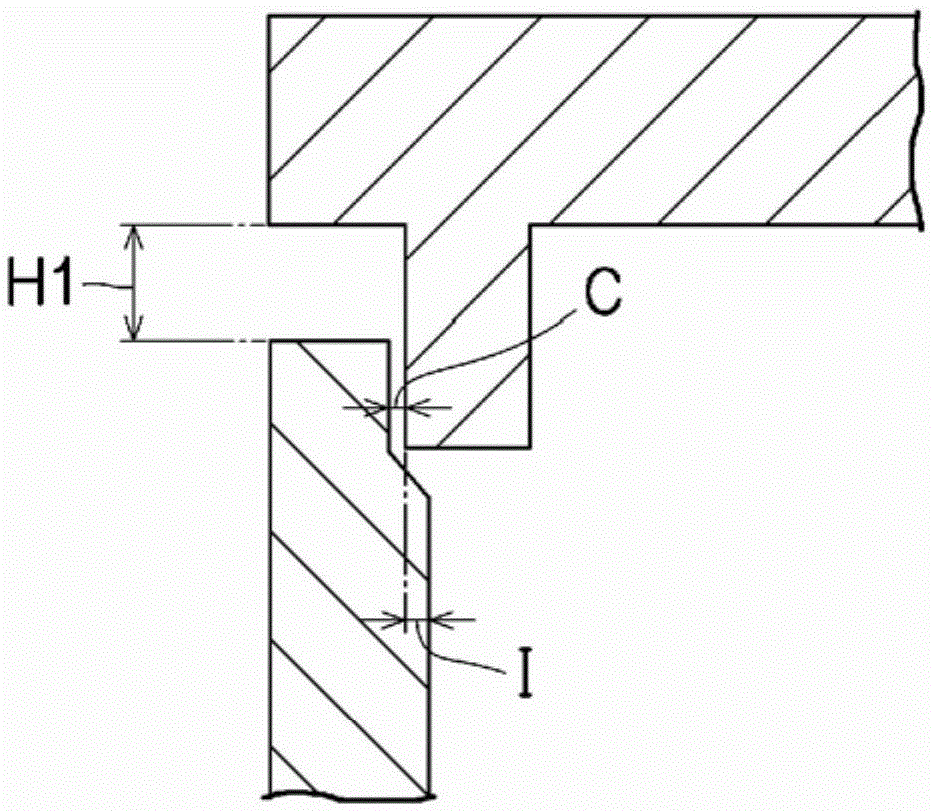

[0048] A hollow fiber membrane bundle made of 9,200 hollow fiber membranes made of polysulfone with an inner diameter of 200 μm and a membrane thickness of 40 μm is inserted into a total length of 285 mm so that both ends protrude 7 mm or more from the end of the main body shell. , The inner diameter of the body is 34.8mm, the inner diameter of the end is 44.2mm, and the outer diameter of the end is 48.2mm. figure 1 Reference numeral 3) on the end faces of the two ends was irradiated with a carbon dioxide laser with an output of 80 W in a predetermined pattern to seal the hollow portion of the end faces of the hollow fiber membrane. Next, install caps on both ends of the main case (refer to Figure 6 Reference numeral 26), the main body shell is rotated with half of the full length of the main body shell as the center axis of rotation, half of the full length is used as the radius of rotation, and the resulting centrifugal force is used to make the inlet port of the treatment...

Embodiment 2

[0053] A hollow fiber membrane bundle made by bundling 16,000 hollow fiber membranes made of polysulfone with an inner diameter of 200 μm and a membrane thickness of 40 μm is inserted into the total length of 285mm, the inner diameter of the body is 45.4mm, the inner diameter of the end is 54.8mm, and the outer diameter of the end is 58.8mm. The hollow part of the end face of the fiber membrane is sealed. Next, in the main shell (see figure 1 Caps are installed at both ends of reference number 3) (refer to Figure 6 ), take half of the full length of the main shell as the central axis of rotation, and use half of the full length as the radius of rotation to rotate the main shell, and use the resulting centrifugal force to make the inlet port of the treatment liquid (refer to figure 1 The reference numeral 1) and the outlet port of the treatment liquid (refer to figure 1 2) The injected polyurethane resin is cured to form a membrane fixing layer at both ends of the main s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com