A method for improving production efficiency and equipment utilization rate of smt patches

A technology of production efficiency and utilization rate, applied in data processing applications, assembly of printed circuits with electrical components, comprehensive factory control, etc., can solve problems such as idle waste of new equipment, difficulties in spare parts, and reduced production line efficiency, so as to improve production efficiency , Reduce equipment idle rate, improve production efficiency and equipment utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

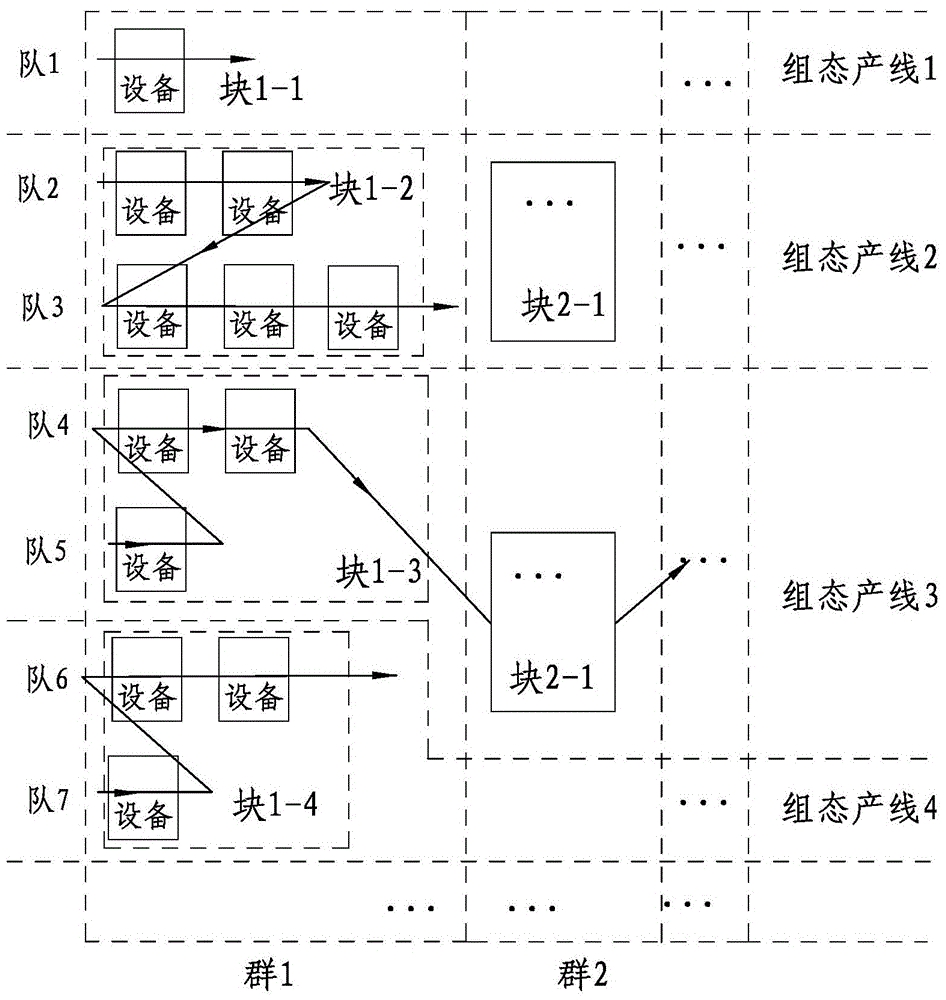

[0034] Attached below figure 1 The present invention is described further:

[0035] A method for improving SMT patch production efficiency and equipment utilization rate,

[0036] The first step is to arrange and classify all the equipment in the workshop in a row and group:

[0037] Column "team": A certain process in the workshop, such as the placement process, has 12 placement machines. As an example, these 12 placement machines are arranged into 7 "teams" (team 1 to team 7). Among the teams, some teams consist of a single device; some teams consist of multiple devices. The 7 teams are arranged in parallel.

[0038] Group "group": the 7 teams in this process form a group (group 1); all existing and available equipment in the same process are also arranged in parallel on the position of the team to form a group (group 2, group 3,...).

[0039] In the second step, during SMT production, the production line configuration is performed in real time according to the equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com