Rotor of synchronous reluctance motor

A synchronous reluctance motor and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem that it is difficult to apply to high-power synchronous reluctance motors, and achieve easy guarantee of structural accuracy, The effect of convenient manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

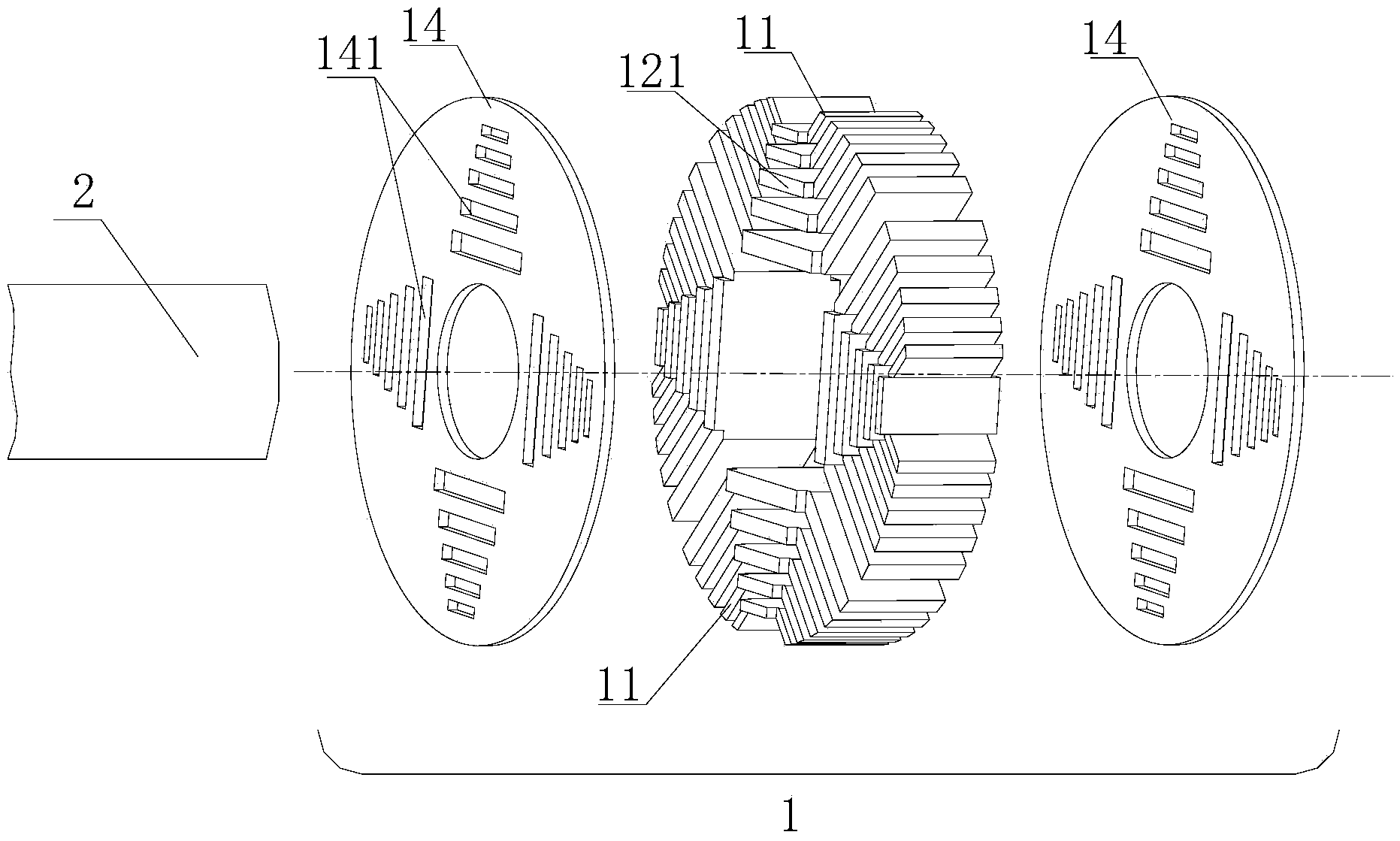

[0042] refer to Figure 1-8 , a synchronous reluctance motor rotor, including a plurality of rotor modules 1 arranged axially and sequentially staggered along a common axis, each rotor module 1 includes a plurality of magnetic poles 11, and the plurality of magnetic poles 11 are arranged in adjacent sections around the common axis Among them, each magnetic pole 11 includes a plurality of magnetic ribs 12 spaced apart in the radial direction, and each magnetic rib 12 is composed of a number of punching pieces 13, and positioning plates 14 are connected to both axial sides of the plurality of magnetic poles 11. The positioning plate 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com