Strain-resistant tower drainage plate bolt tightener

A technology of plate bolts and fasteners, which is applied in the field of tension tower drainage plate bolt fasteners, which can solve problems such as high risk, personal casualties, and easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

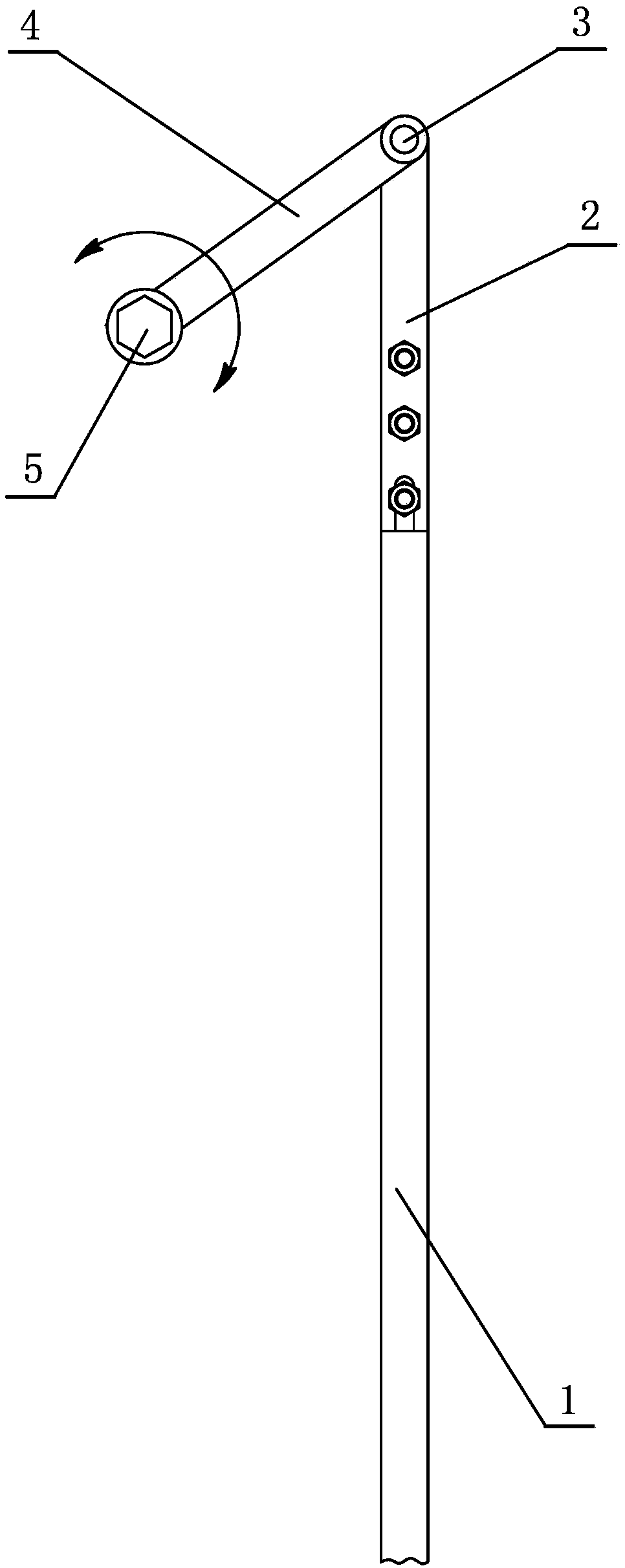

[0013] Example: such as figure 1 , figure 2 As shown, the bolt tightener of the strain tower diversion plate has a slender insulating rod 1, the front end of the insulating rod 1 is hinged to a connecting rod 4 through a rotating shaft, and the other end of the connecting rod 4 is fixedly connected with the sleeve wrench 5 , Sleeve wrench 5 cooperates with the end cap and the nut of the drain plate bolt.

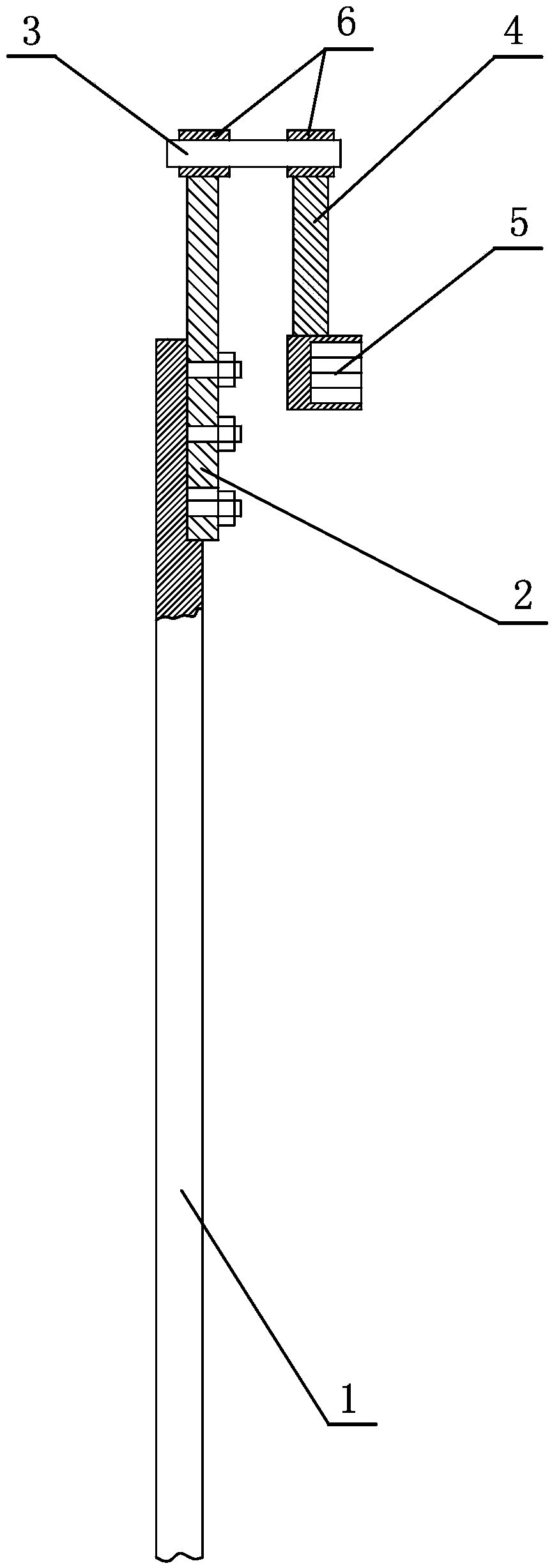

[0014] For the insulating rod 1 with low strength, a plate joint 2 of high-strength material can be installed at the front end of the joint 2. The front end of the joint 2 is provided with a shaft sleeve 6, and the shaft sleeve 6 is rotatably connected with the rotating shaft 3. The other end of the rotating shaft 3 It is rotatably connected with the shaft sleeve 6 at one end of the connecting rod 4 .

[0015] When working, the operator can image 3 As shown, stand on the cross arm of the pole tower, extend the insulating rod 1, clamp the casing wrench 5 at the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com