Gas insulated switchgear

A technology for gas-insulated switches and equipment, applied in electrical switches, high-voltage/high-current switches, electrical components, etc., can solve the problems of inappropriateness, simplified manufacturing process, and evaluation of the deterioration degree of permanent magnets, which takes a lot of effort and time. , to achieve the effect of low operating force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

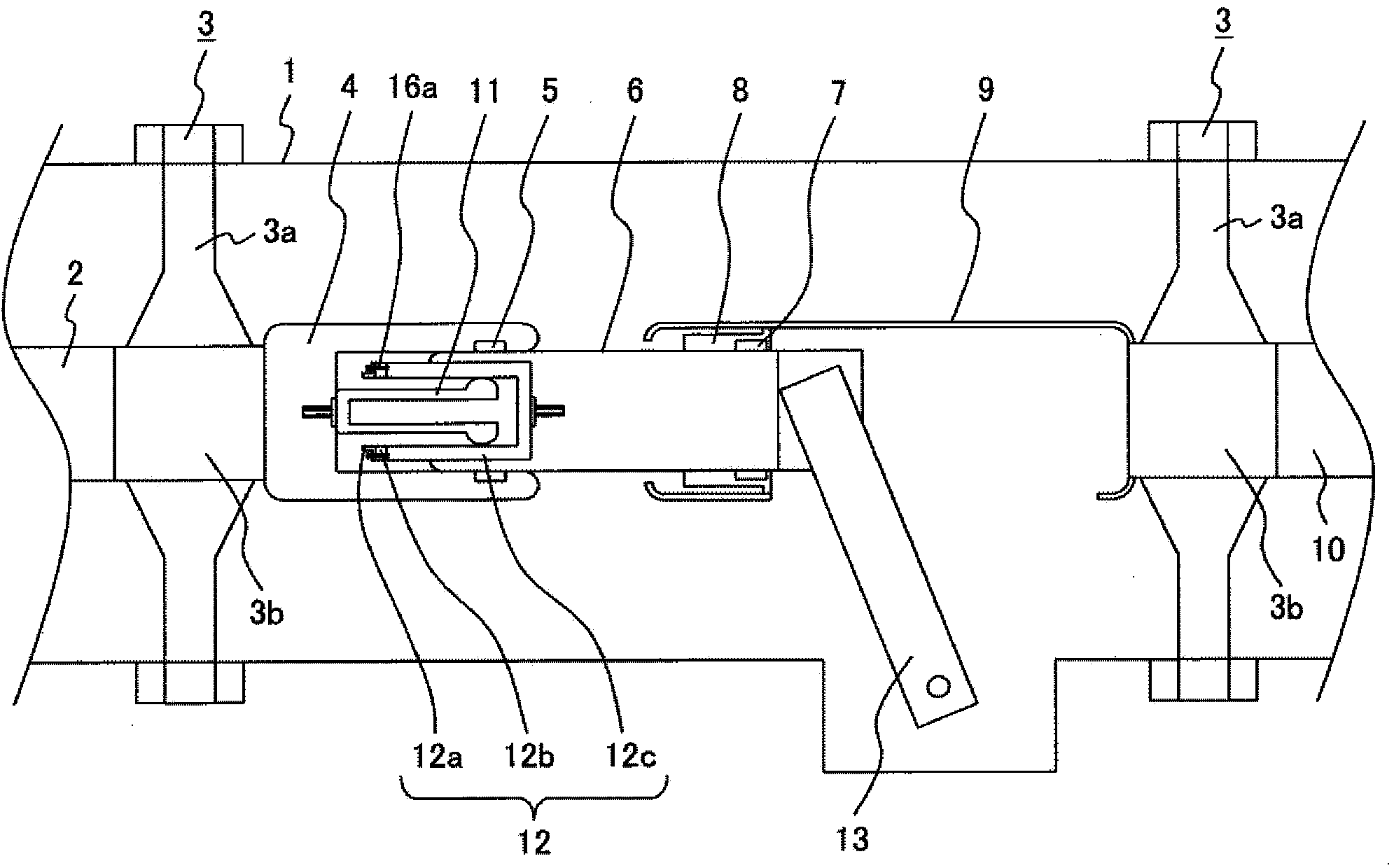

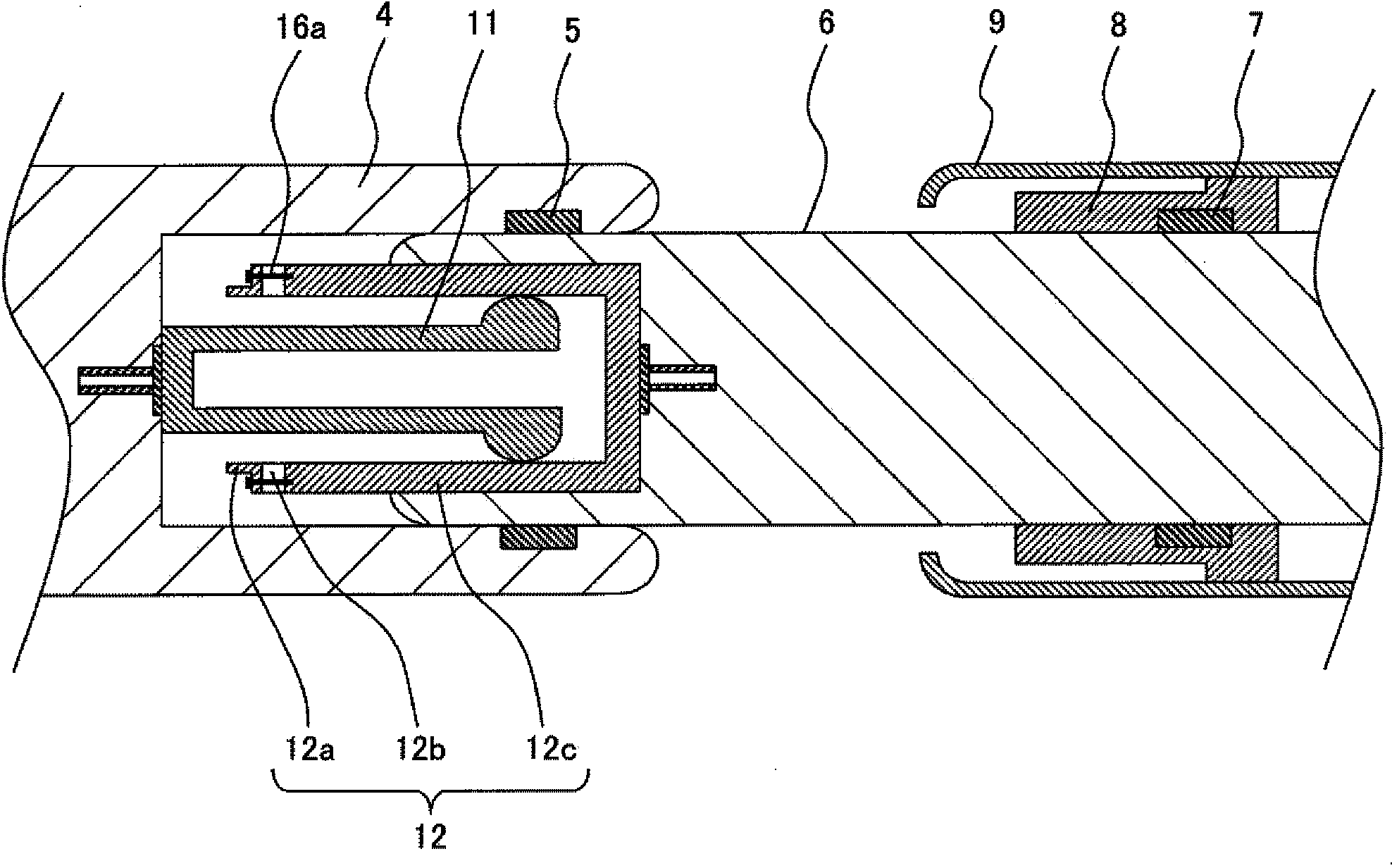

[0034] figure 1 It is a sectional view showing a closed state of the gas insulated switchgear according to the first embodiment of the present invention.

[0035] As shown in the figure, the gas insulated switchgear of this embodiment forms a gas compartment in the airtight container 1 through the support insulator 3, and seals SF in the gas compartment. 6 Negative gas such as gas, dry air, nitrogen, carbon dioxide, SF including negative gas 6 / N 2 Mixed gas, N excluding negative gas 2 / O 2 Mixed gas etc. are used as insulating gas.

[0036] The support insulator 3 is provided with an insulator 3a around it, and an embedded conductor 3b is arranged at the center, and the embedded conductor 3b supports and fixes the stator conductors 4 and The movable element conductor 9 and the opposing portions of these stator conductors 4 and the movable element conductor 9 are each formed in a curved shape, and the electric field relaxation shield effect is provided by being formed in ...

Embodiment 2

[0067] Figure 7 Shows the equivalent of another fixing method of the gas insulated switchgear according to Embodiment 2 of the present invention Figure 4 The enlarged cross-sectional view of the main part.

[0068]This embodiment is a modified example of the method of fixing the convex electrode 12a, the spacer 12b, and the cylindrical electrode 12c described in the first embodiment of the present invention, and differences from the first embodiment will be described here.

[0069] exist Figure 7 The present embodiment shown is characterized in that, in fixing the convex electrode 12a, the spacer 12b and the cylindrical electrode 12c, a fixing member 16b made of metal such as SUS is used to ensure the stability described in the first embodiment. The fixing strength of the insulating fixing member 16a or more.

[0070] That is, in this embodiment, if Figure 7 As shown, a metal fixing member 16b is used to fix the convex electrode 12a, the spacer 12b and the cylindrical ...

Embodiment 3

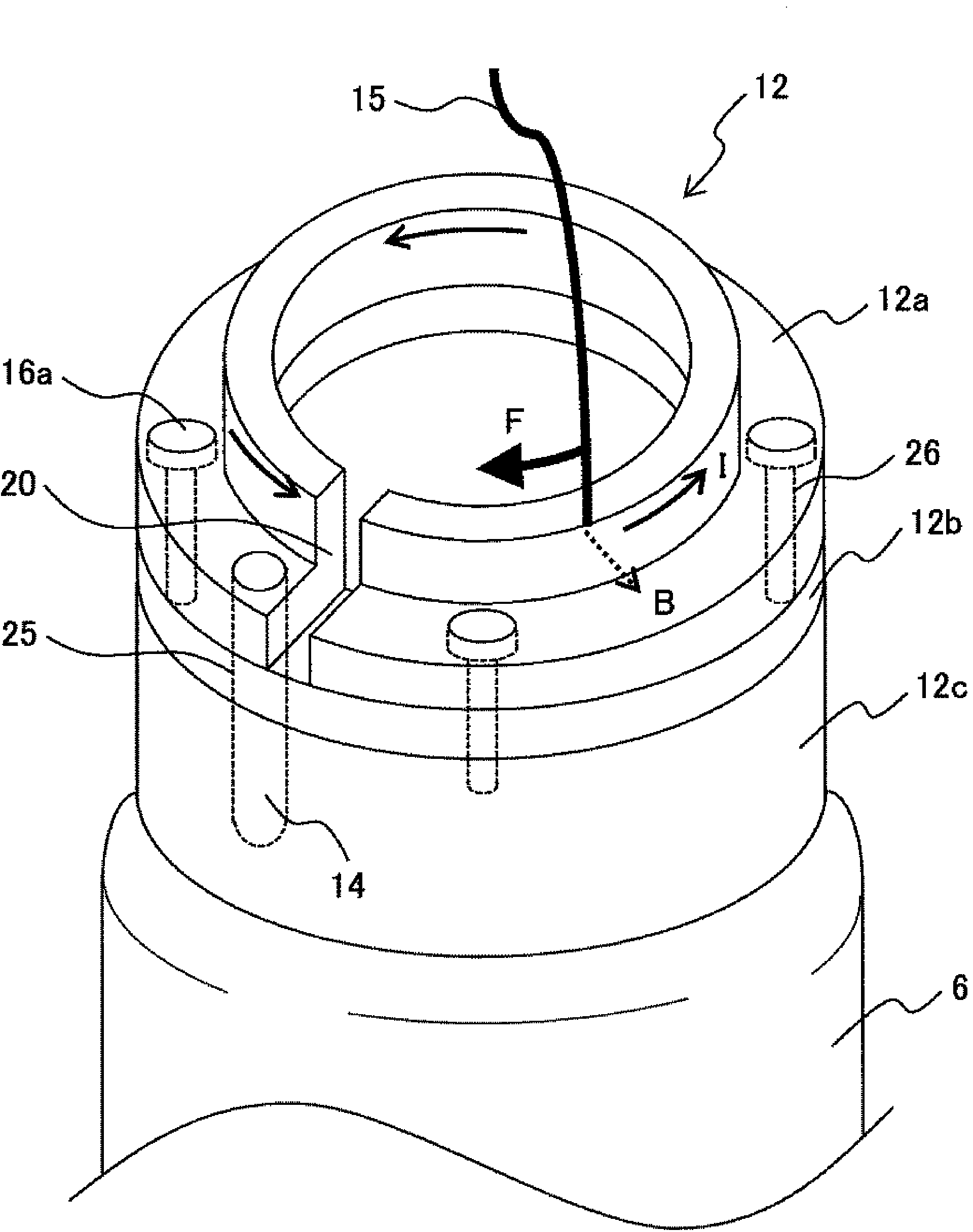

[0075] Figure 8 It is a perspective view viewed from the direction of the opposite front end of the movable arc contactor 12 of the gas insulated switchgear according to Embodiment 3 of the present invention.

[0076] This embodiment is a modified example using the method of fixing the convex electrode 12a, the spacer 12b, and the cylindrical electrode 12c described in Embodiments 1 and 2 of the present invention. Here, differences from Embodiment 2 will be described. .

[0077] Such as Figure 8 As shown, in this embodiment, it is characterized in that the width w generated by the difference in the distance between the outer diameter of the large-diameter portion and the outer diameter of the small-diameter portion of the convex electrode 12a 1 A ring-shaped (cylindrical) insulating fixing spacer 19 that is a third spacer is arranged in the middle, and the convex electrode 12a, the spacer 12b and the cylindrical electrode 12c are fixed by the fixing spacer 19 .

[0078] u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com