Voltage balancing detection apparatus for electric locomotive rectifier cabinet

A technology for detection devices and electric locomotives, applied to measuring devices, measuring current/voltage, measuring electrical variables, etc., can solve problems such as low efficiency, danger, electric shock, etc., to avoid electric shock, improve work efficiency, and record data conveniently Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

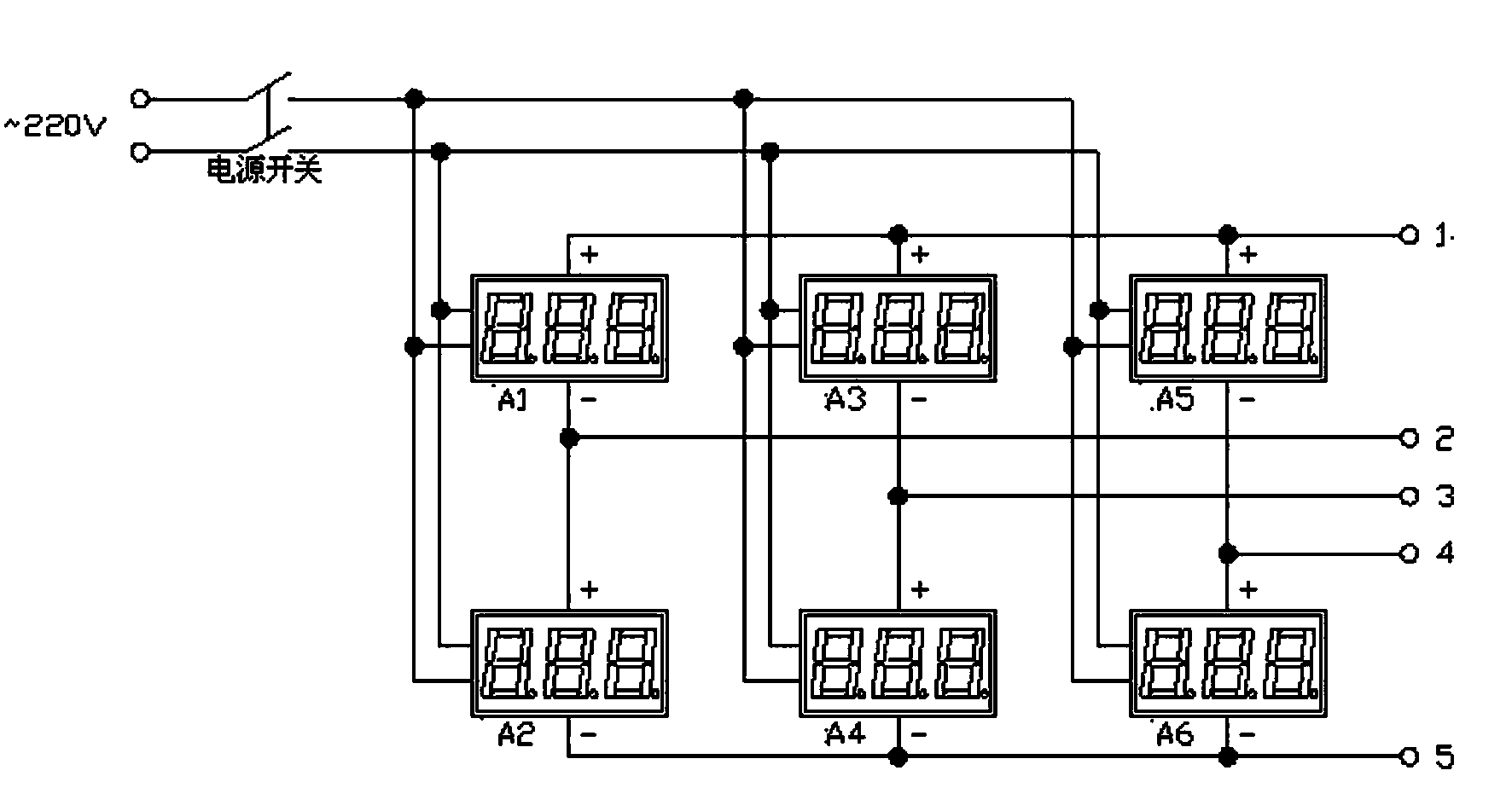

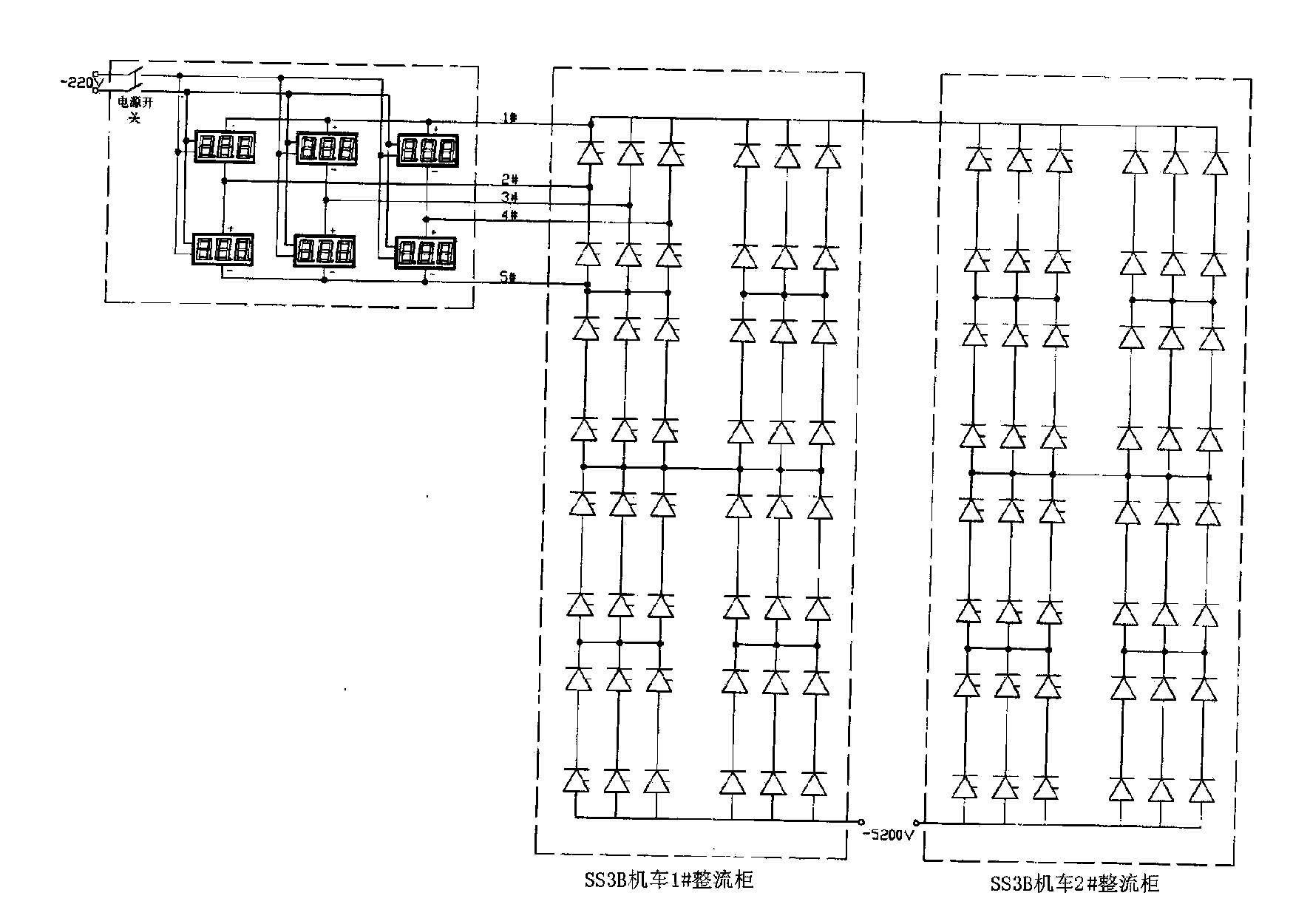

[0010] Such as figure 1 As shown, the present invention adopts every two voltmeters in series to form at least three groups, a total of 6 voltmeters A 1 ~A 6 , the voltmeters are all digital display DC voltmeters, the series contacts of each two voltmeters respectively lead to an external measurement terminal 2, 3, 4, and the positive connection contacts of the voltmeters in series lead to an external measurement terminal 1, and the negative connection The contact leads to an external measuring terminal 5, which is the first group of voltmeters A 1 The negative terminal of the voltage input and the voltmeter A 2 The positive end of the voltage input is connected to the contact and leads to an external measuring end 2. The second group of voltmeters A 3 The voltage input negative terminal of the voltmeter A4 is connected with the voltage input positive terminal of the voltmeter A4 to draw an external measuring terminal 3 . The third group of voltmeter A 5 The voltage inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com