Device for detecting fabric surface of acoustic component of automobile

An acoustic component and surface detection technology, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of low detection efficiency, time-consuming, and high requirements on the surface profile of fabrics, and achieve less time-consuming detection and high detection efficiency , easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples.

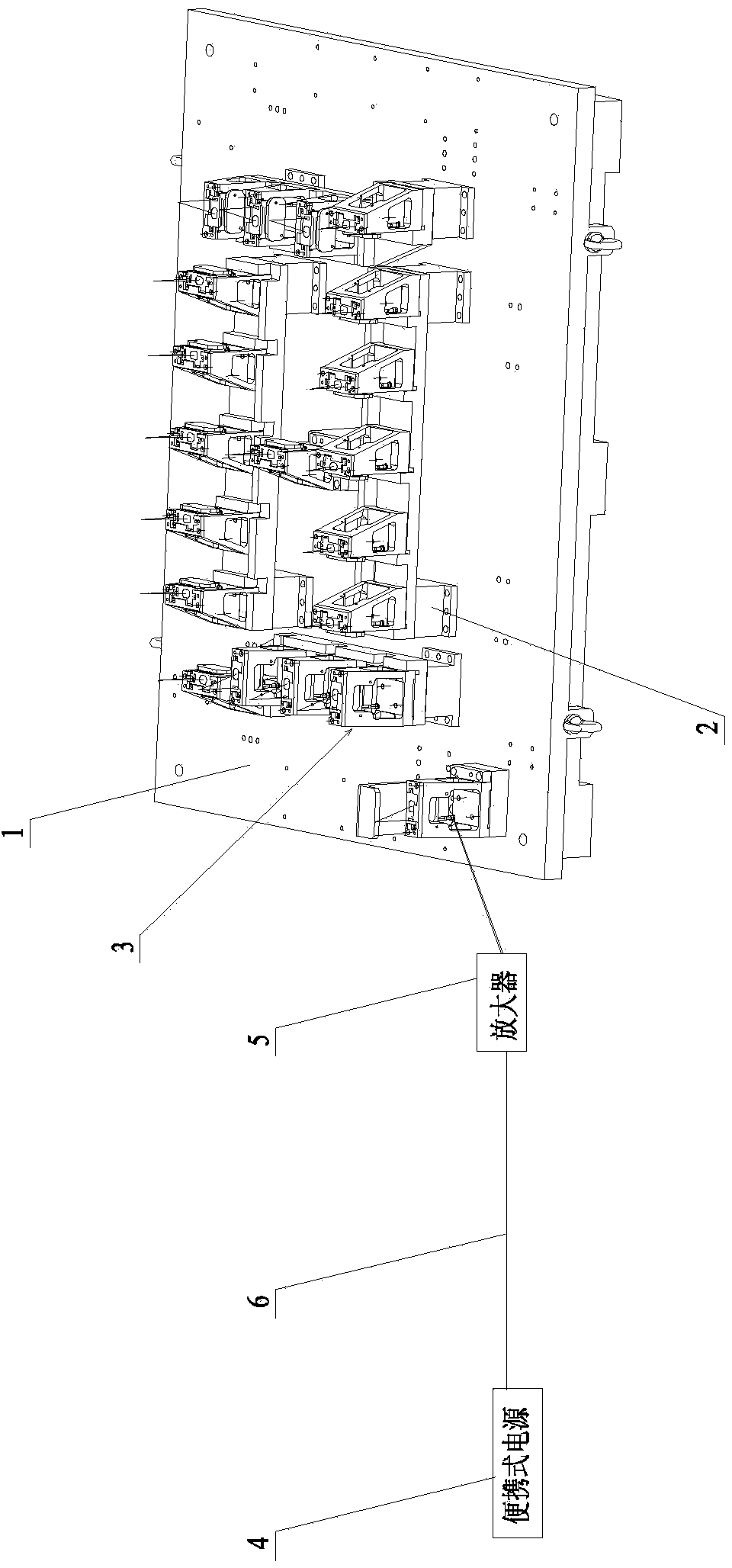

[0012] The detection device for detecting the surface of the automotive acoustic components has a detection platform support seat 2 fixed on the installation base plate 1, and a number of laser detection mechanisms 3 are fixed on the upper surface of the detection platform support base 2. There is a portable power supply 4 and an amplifier 5, the portable power supply 4 is connected to the amplifier 5 through a cable 6, and the amplifier 5 is connected to the laser detection mechanism 3 through a cable 6.

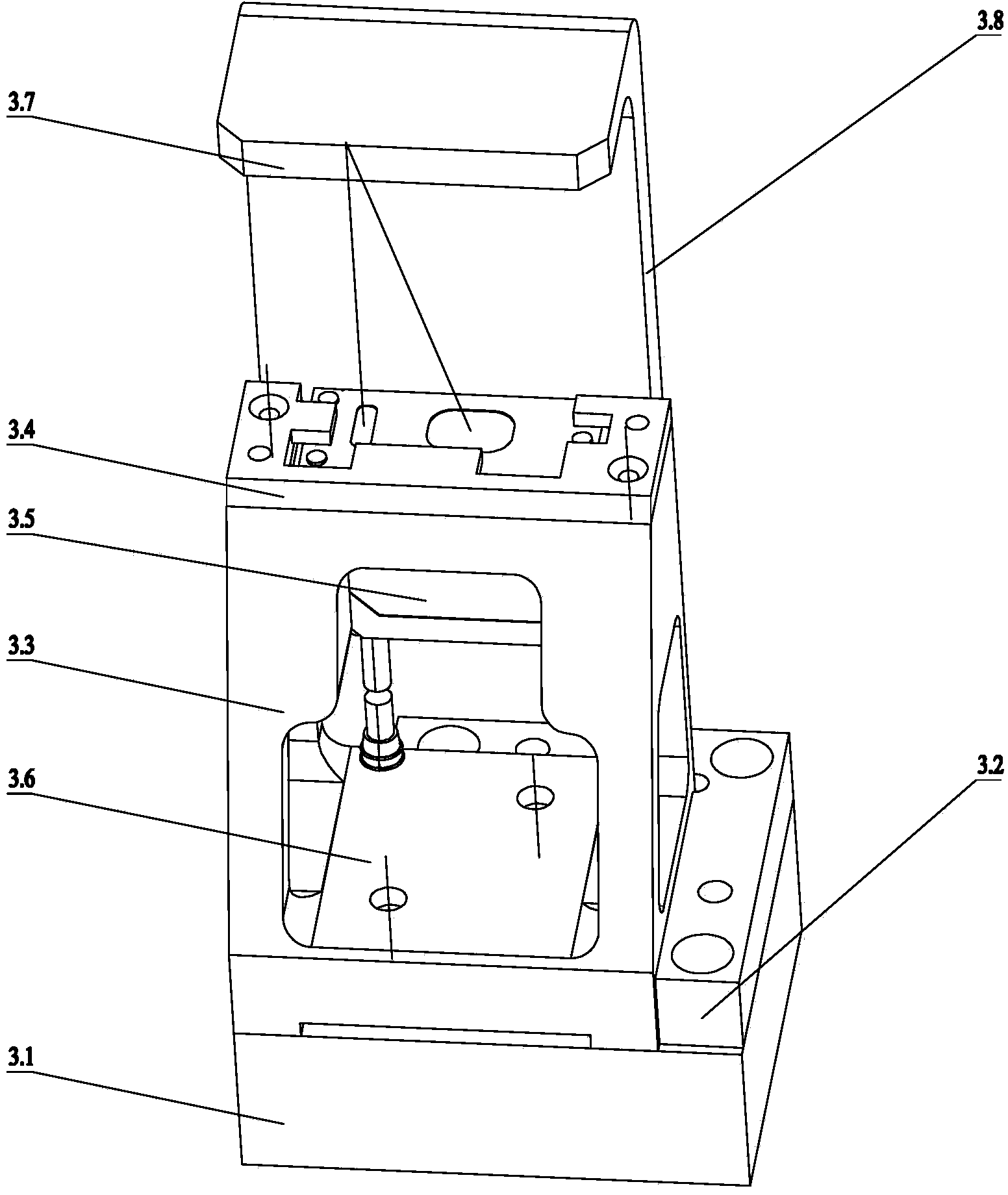

[0013] The laser detection mechanism 3 includes a zero calibration support 3.1, a zero calibration reference block 3.2, a sensor support 3.3, an end cover plate 3.4, a laser displacement sensor probe 3.5, a zero calibration standard panel 3.6, a magnet 3.7 and a connecting plate 3.8; The upper surface of the zero support 3.1 is fixed with a zero reference block 3.2 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com