Vortex compressor as well as fixed vortex member and movable vortex member

A technology of scroll compressors and fixed scrolls, which is applied in the field of scroll compressors, can solve the problems of affecting the performance of the compressor refrigeration system, deteriorating the reliability of the compressor, and increasing the manufacturing cost, so as to improve the energy efficiency ratio and work efficiency. Stability, avoiding complex manufacturing process, suppressing the effects of high noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be described in detail below by means of exemplary embodiments with reference to the drawings. The following detailed description of the present invention is for the purpose of illustration only, and in no way limits the present invention and its application or use.

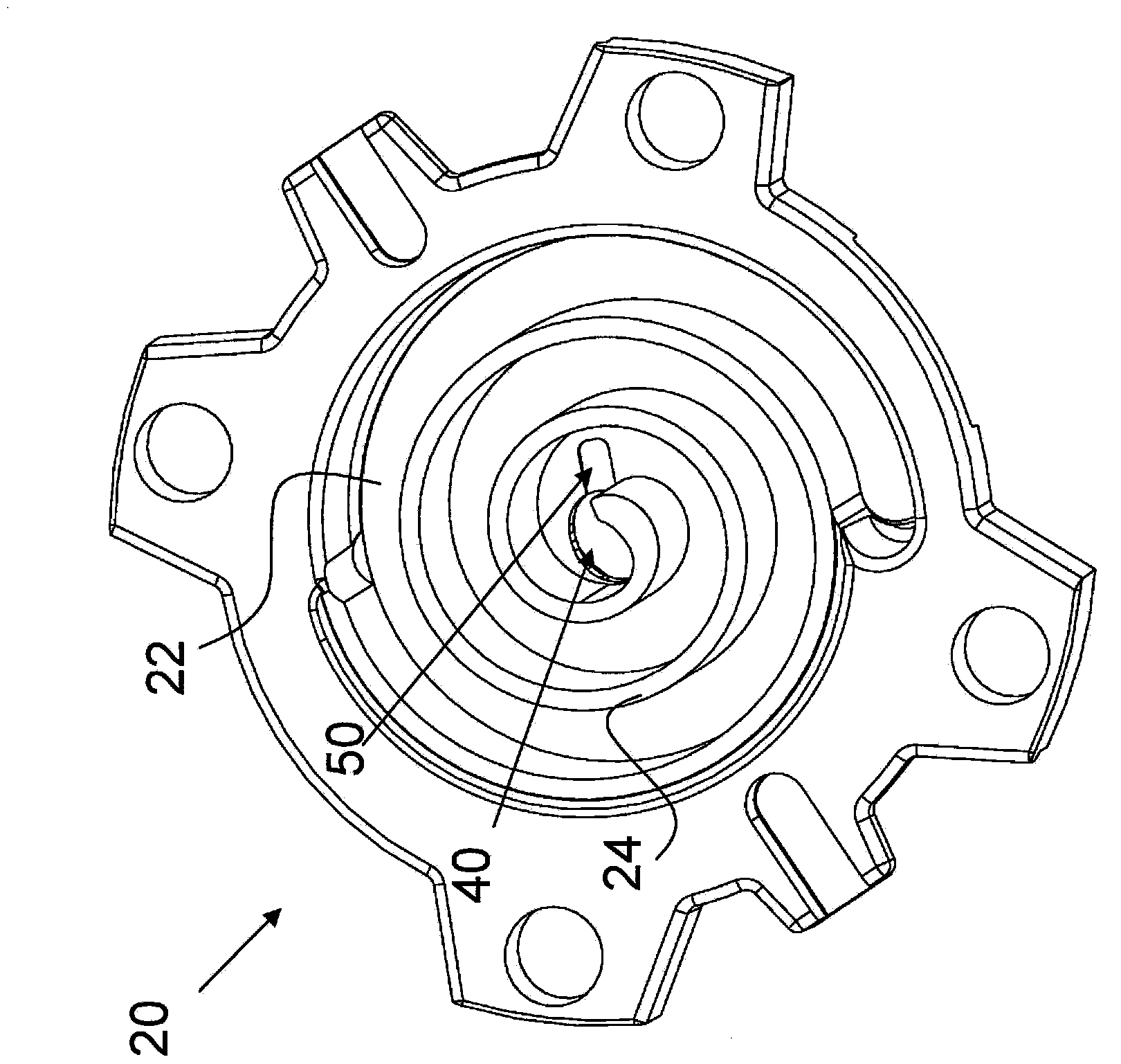

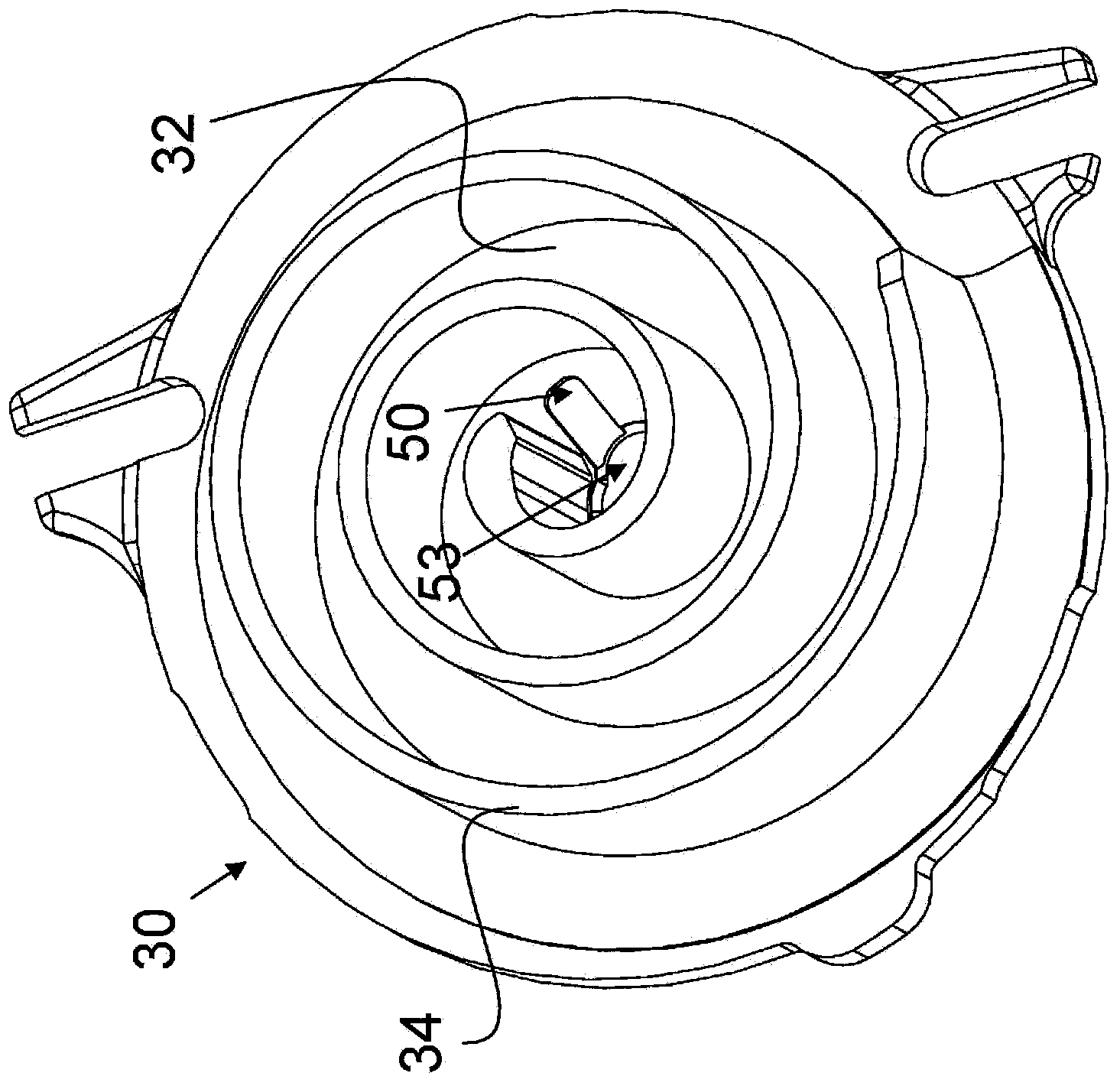

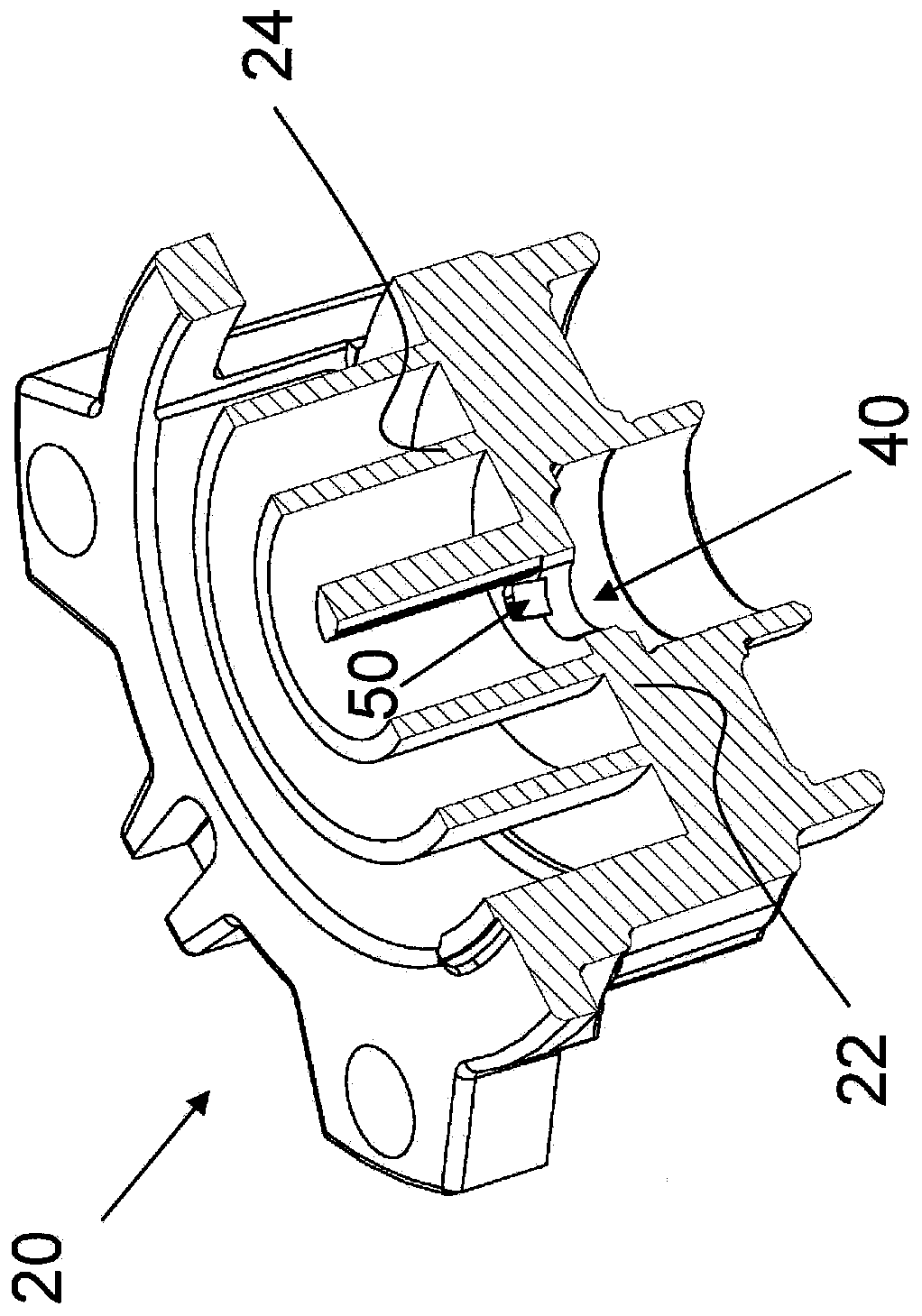

[0036] First, refer to Figure 1 to Figure 7 The structure of the compression mechanism of the scroll compressor according to the first embodiment of the present invention is described, in which figure 1is a perspective view showing a fixed scroll member of a compression mechanism according to a first embodiment of the present invention, figure 2 is a perspective view showing an orbiting scroll member of a compression mechanism according to a first embodiment of the present invention, image 3 is a longitudinally sectional perspective view showing a fixed scroll member according to a first embodiment of the present invention, Figure 4 is a longitudinally sectional perspective view ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com