Pump

A pump chamber and component technology, applied in the field of spool sheath construction, can solve the problems of difficulty in increasing the compression ratio, thickening of the top panel 105, and complicated assembly procedures, so as to reduce the useless space and thin the pump head. part, the effect of increasing the compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

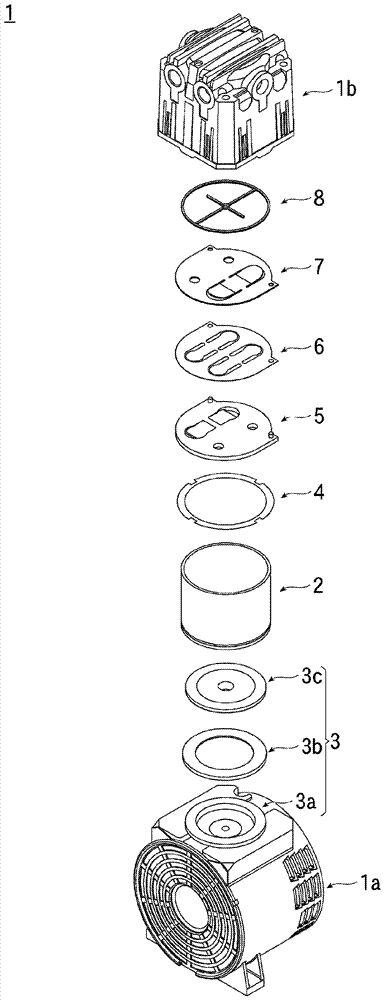

[0037] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

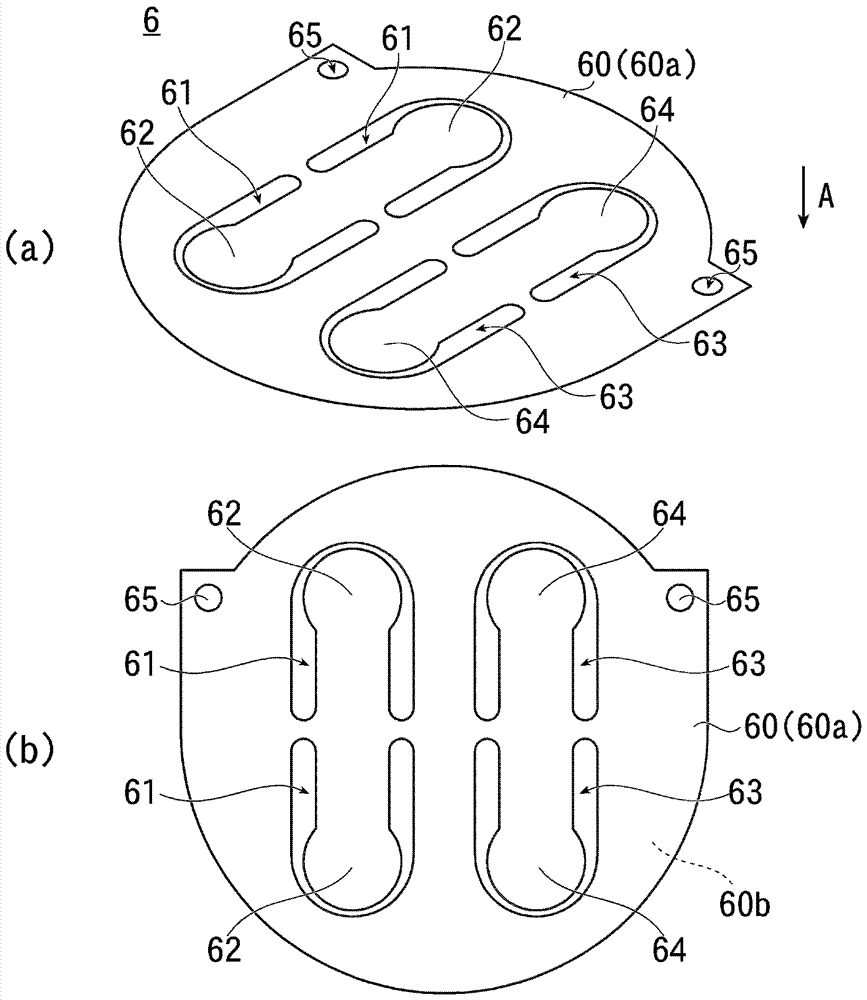

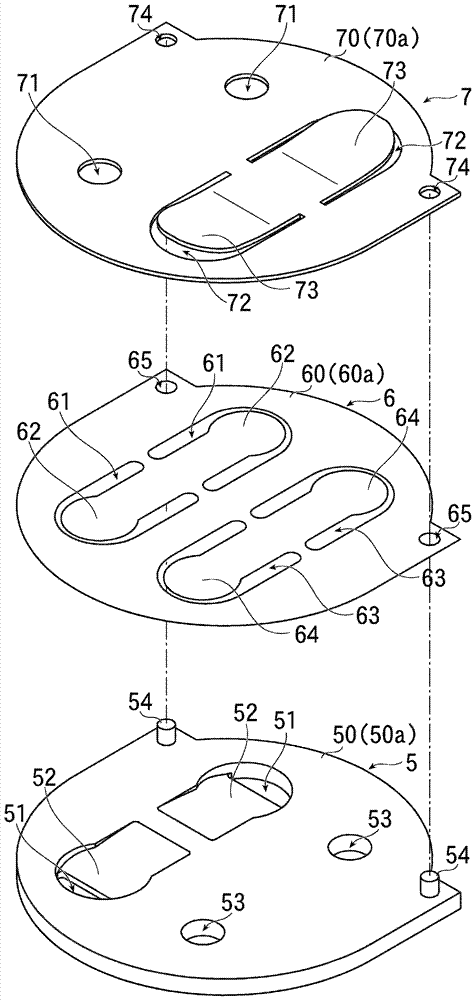

[0038] figure 1 It is an exploded perspective view showing the configuration of main parts of an embodiment of the pump according to the present invention.

[0039] like figure 1 As shown, the pump 1 of the present embodiment is provided with a top cover 1b on an upper portion of a drive unit 1a (the driving source is omitted in the figure), and the following components are arranged inside the top cover 1b.

[0040] A pump chamber 2 is provided on the upper part of the driving part 1a, and a piston part 3 reciprocatingly moved by an eccentric shaft fastened to a motor (not shown) is inserted into the pump chamber 2 .

[0041] The piston part 3 is constituted by screwing a cup seal 3b and a cup seal hold-down plate 3c, which perform a sealing function while sliding, to a connecting rod 3a.

[0042] On the other hand, a top plate 5 is attached to an upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com