System and method for a movable exhaust aftertreatment device in an internal combustion engine

A technology of exhaust post-treatment and internal combustion engine, which is applied in the direction of electronic control of exhaust treatment device, internal combustion piston engine, exhaust device, etc., and can solve the problem of not providing flow control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be explained in more detail based on a number of exemplary embodiments and with reference to the accompanying drawings.

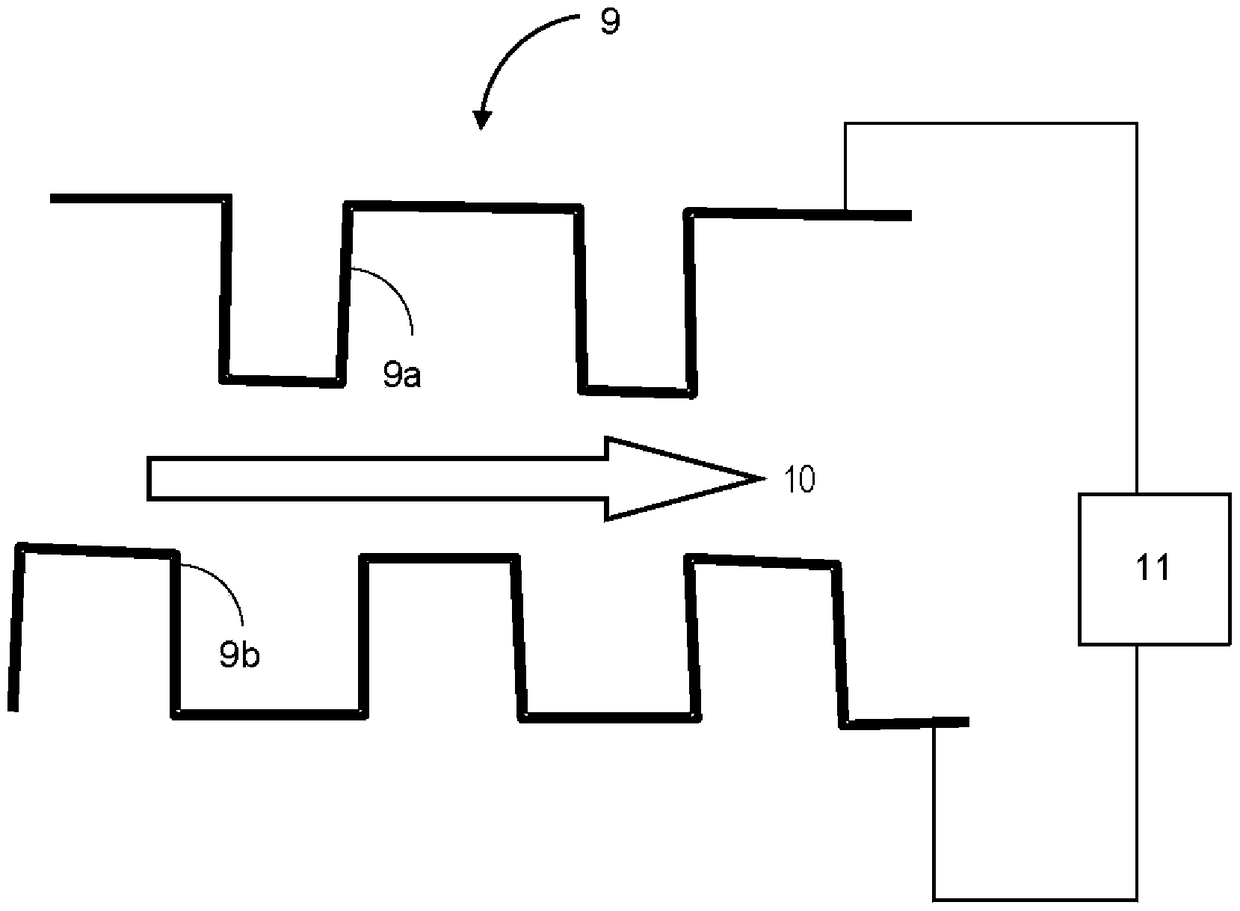

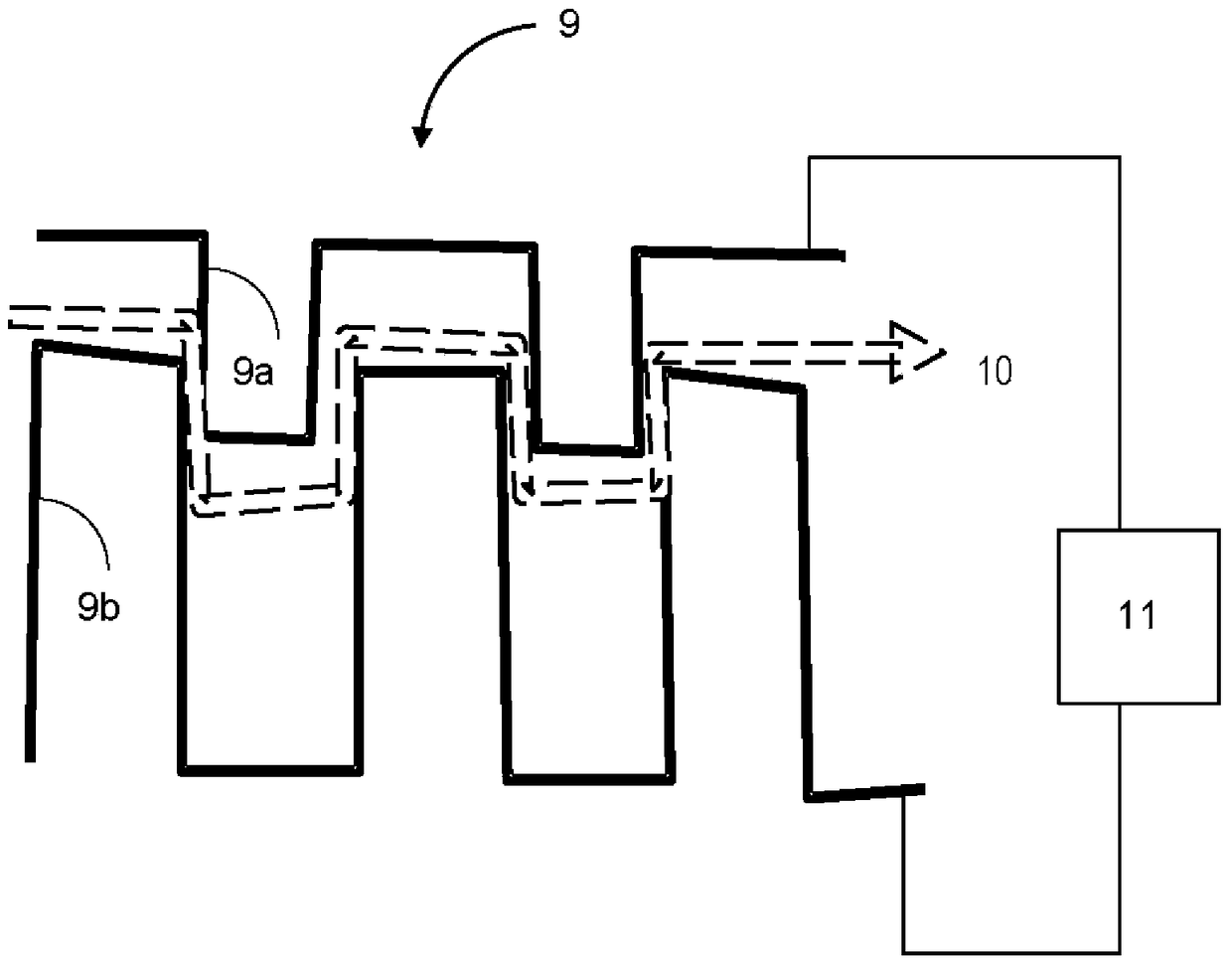

[0031] figure 1 is a schematic illustration for explaining the configuration of the exhaust aftertreatment device 3 including the filter passage 9 in the exhaust system 1 of the vehicle.

[0032] exist figure 1 In this case, an internal combustion engine 2 with a turbocharger 22 , for example a diesel engine, introduces fresh air from an air filter 4 , which is precompressed by a compressor 22 a of the turbocharger 22 . In the exhaust line 5 downstream of the turbine 22b of the turbocharger 22, the exhaust gas of the internal combustion engine 2 flows successively through the oxidation catalytic converter and / or the NOx storage catalytic converter 6, the diesel particulate filter 7 and the rear muffler 8.

[0033] Control system 14 may include a plurality of sensors 16 that send signals to controller 12 . A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com