Surrounding rock control method for large-section dismantling tunnel of fully-mechanized mining face

A fully-mechanized mining face and retraction channel technology, which is applied in the field of surrounding rock control for large-section retraction channels in fully-mechanized mining faces with extra-large mining heights, can solve the problems of poor control of surrounding rocks and high maintenance costs for large-section retraction channels. Achieve the effect of reducing the cost of retraction, reducing the cost of excavation and support, and shortening the formation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

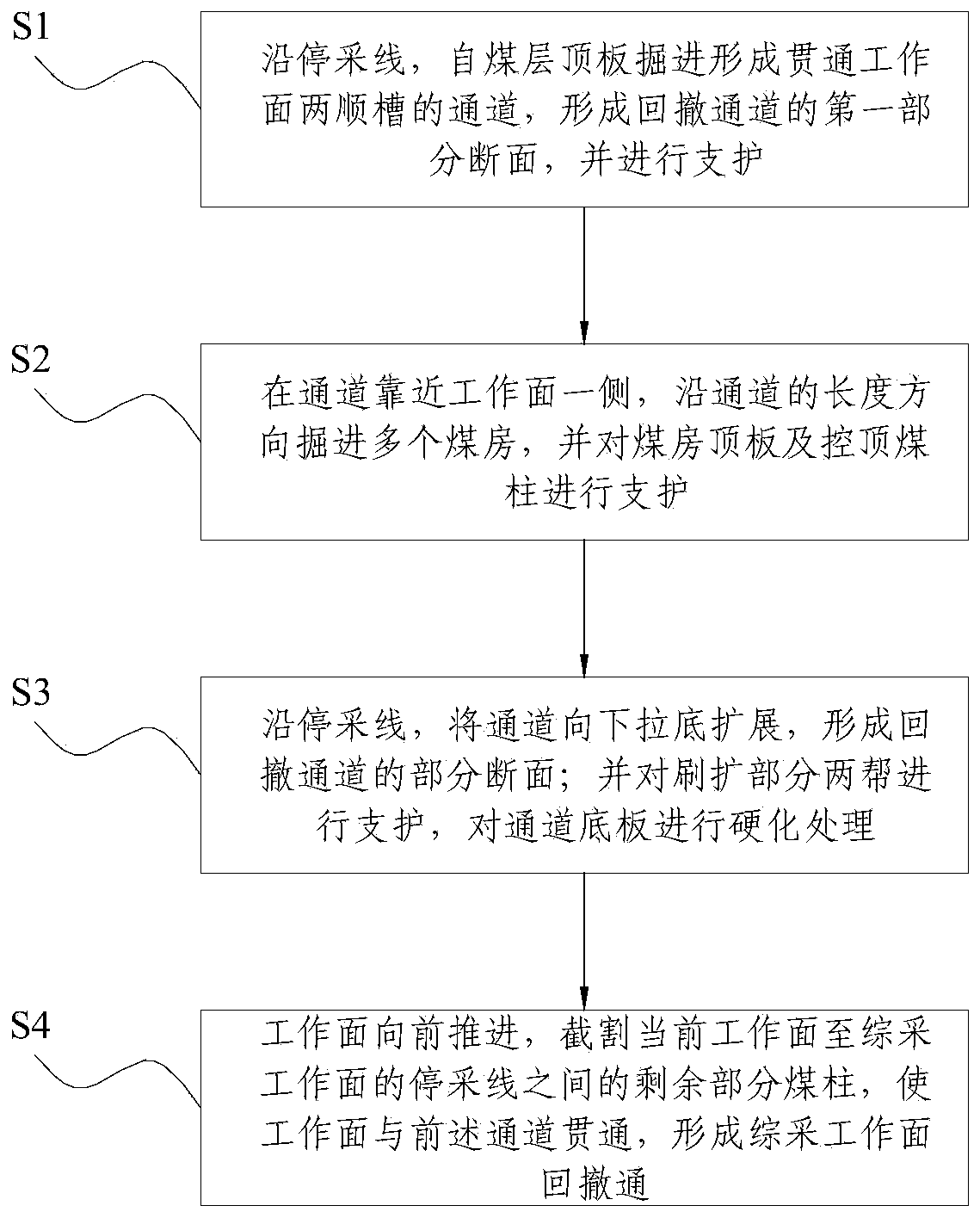

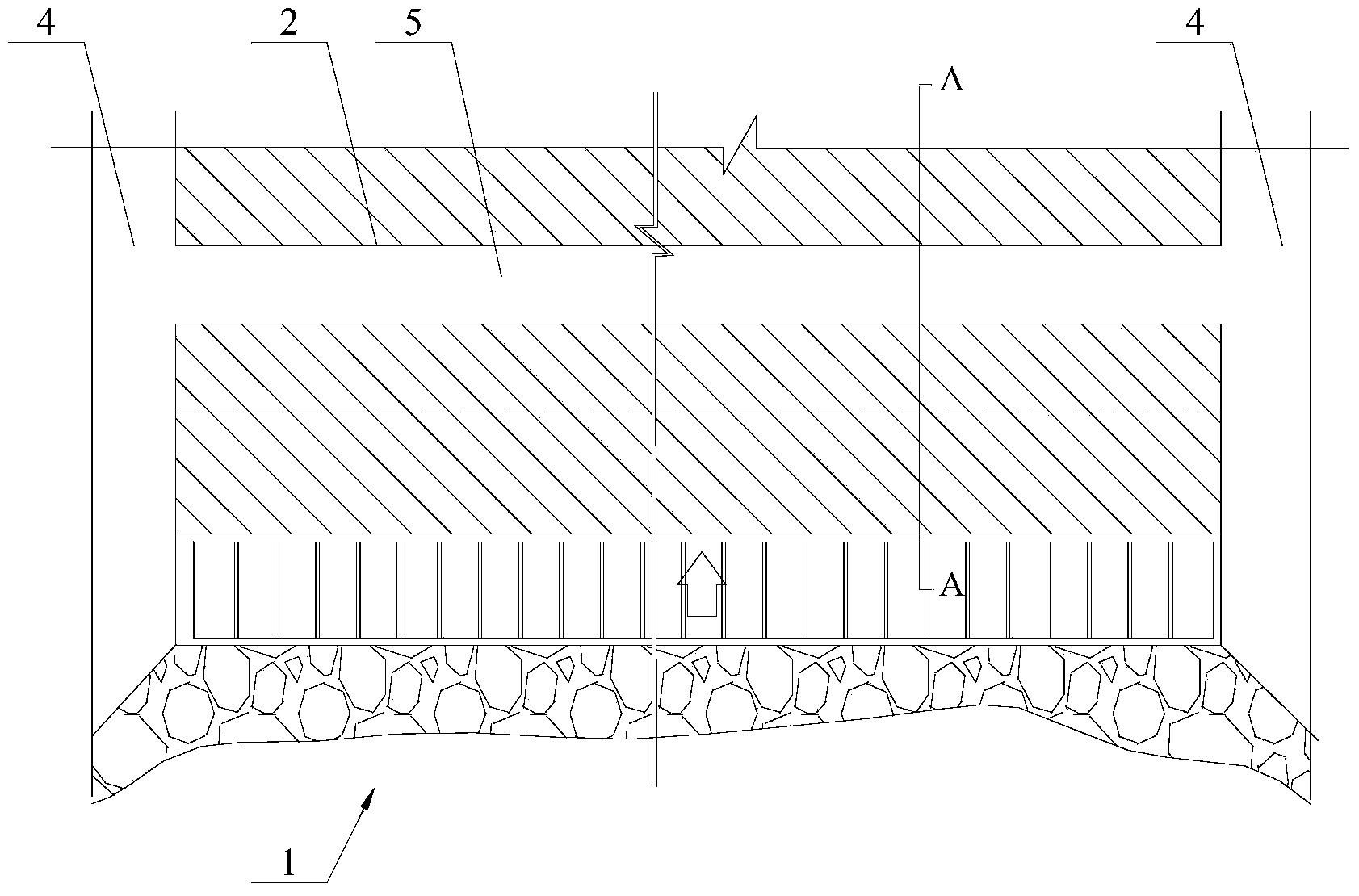

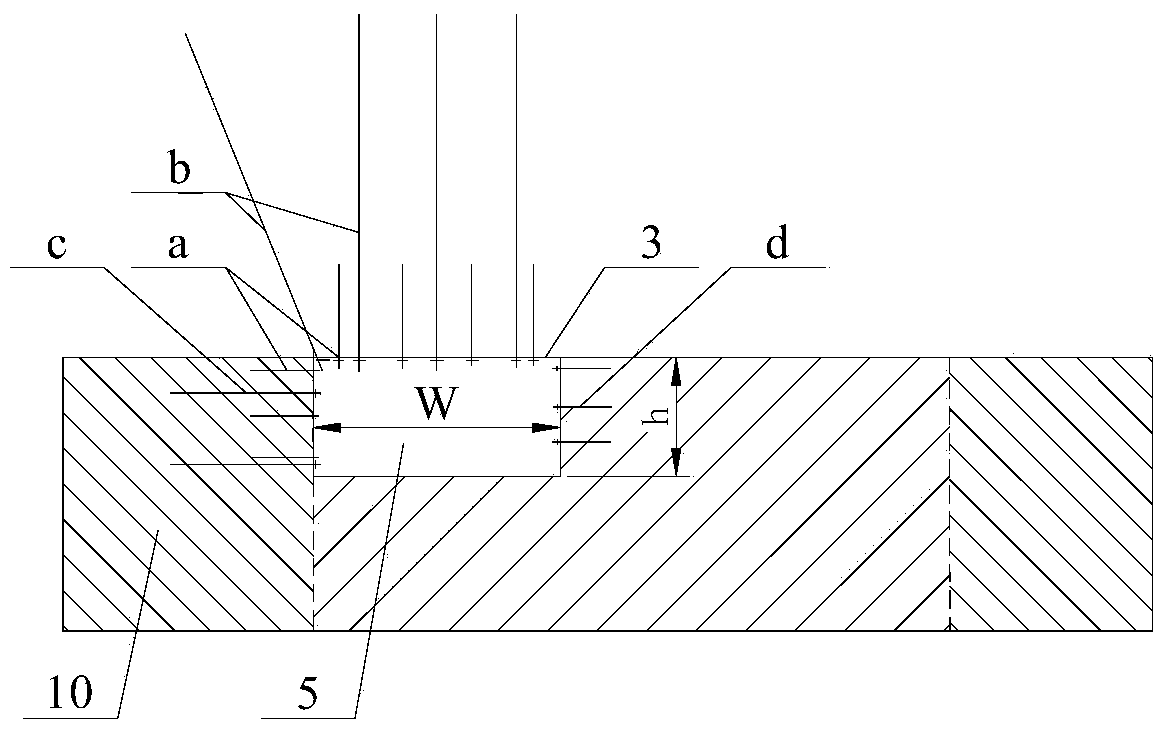

[0054] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0055] Based on the conventional moving technology, the retraction channel takes a long time to form, the stability of the coal wall is poor, and the single-channel retraction space is relatively narrow, which is not conducive to the withdrawal of extra-large mining heights and heavy equipment; and the existing dual-channel moving retraction technology has high moving costs and investment. Due to the shortcomings of large coal pillars and large losses, this embodiment provides a new method for controlling the surrounding rock of the withdrawal channel of the fully mechanized mining face. What needs to be clarified is that the so-called "retraction channel" refers to the withd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com