High-strength bamboo composite material dismountable board house

A composite material, dismantling technology, applied in construction, building structure and other directions, can solve the problems of poor mechanical properties, thin plates, inconvenient transportation, etc., to improve the anti-rolling ability, excellent thermal insulation performance, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

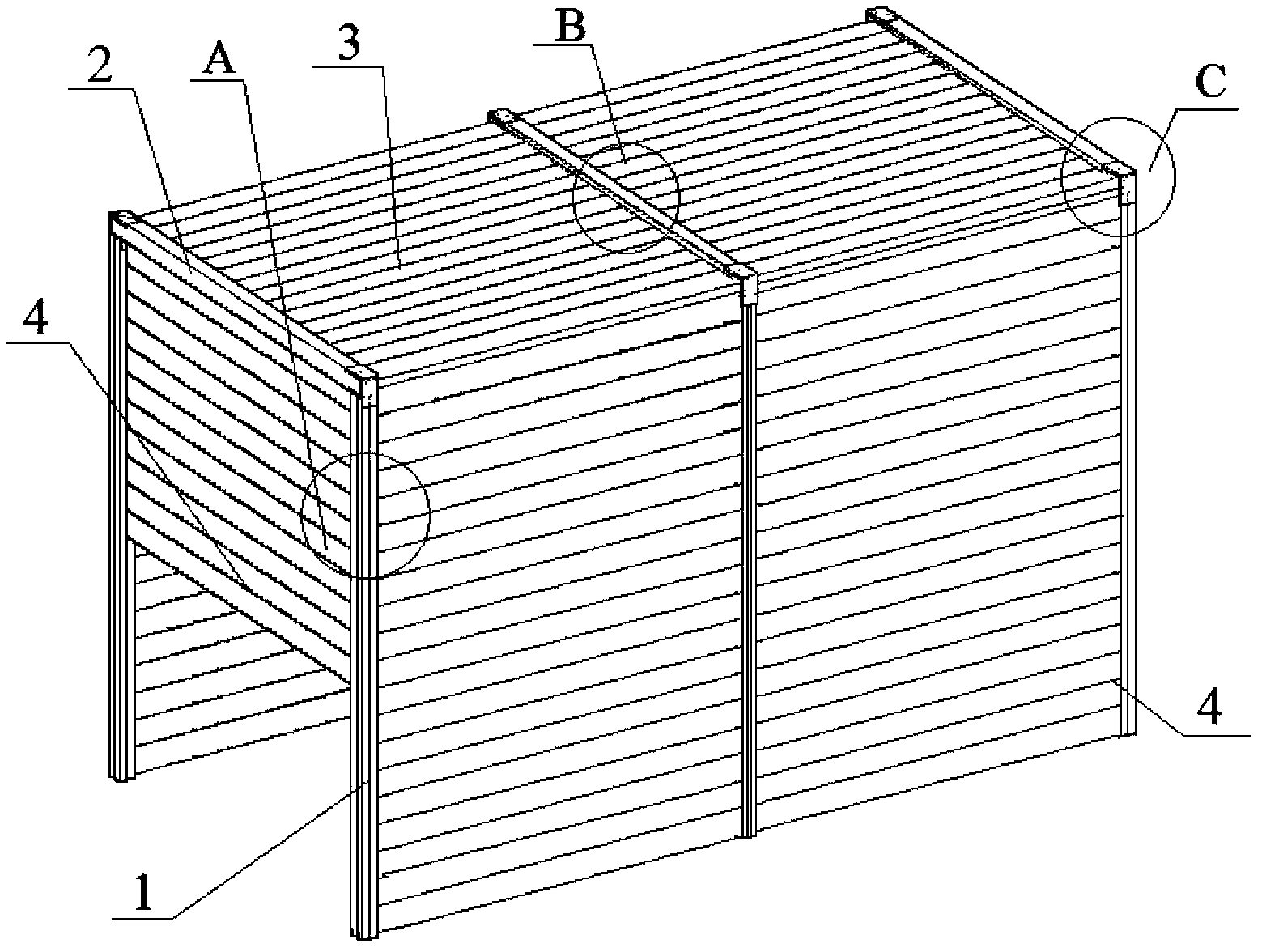

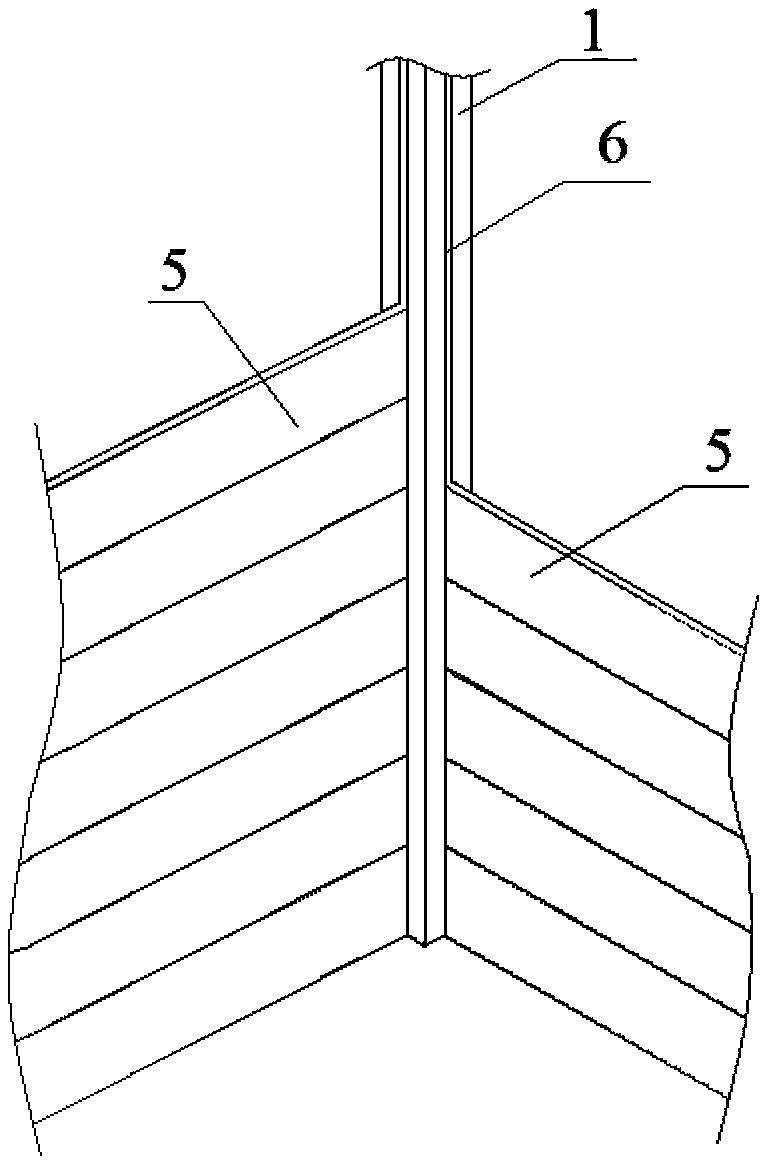

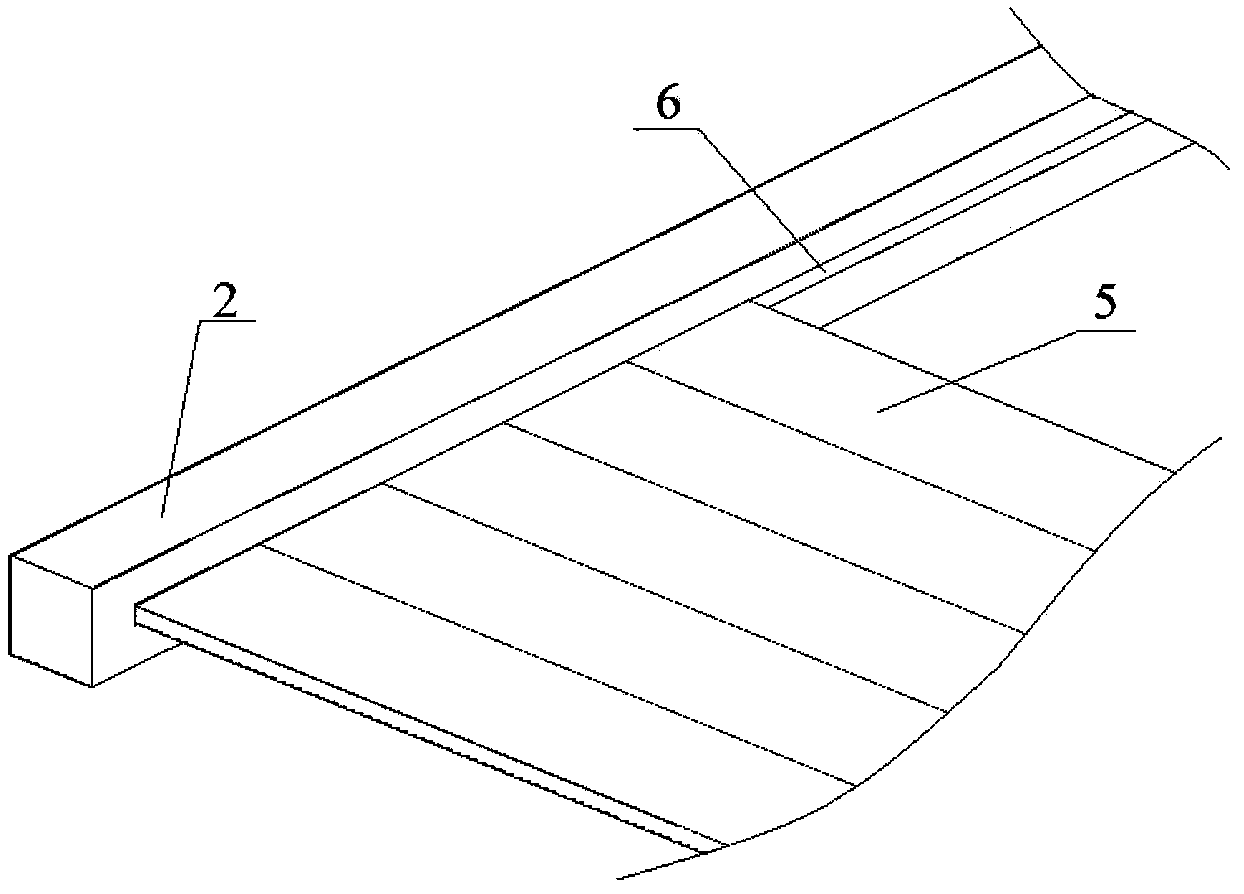

[0023] A high-strength bamboo composite material detachable panel house, such as Figure 1 to Figure 4 As shown, it includes a frame, a top plate 3 and a side plate 4. The frame is composed of columns 1 and beams 2. The number of columns 1 is an even number greater than 2, and the number of beams 2 is half of the number of columns 1. The columns 1 are set perpendicular to the ground. Every two columns 1 are connected by a beam 2, and the columns 1 and beams 2 are connected by L-shaped steel connecting plates 7 and bolts 8. The four sides of the column 1 are provided with card slots 6 , and a plurality of inserting plates 5 are plugged into the card slots 6 of two adjacent columns 1 and spliced to form side plates 4 . Both horizontally opposite sides of the beam 2 are provided with slots 6 , and a plurality of inserting plates 5 are plugged into the slots 6 of two adjacent beams 2 to form the top plate 3 .

[0024] Wherein, the upright column 1 and the beam 2 are bamboo comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com