Wood-plastic plank road wood

A plank road and wood-plastic technology, applied in the field of wood-plastic molding equipment, can solve the problems of non-corrosion resistance, low compression resistance, water absorption, etc., and achieve the effects of easy disassembly, maintenance and saving natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following further description in conjunction with the accompanying drawings does not limit the scope of the present invention.

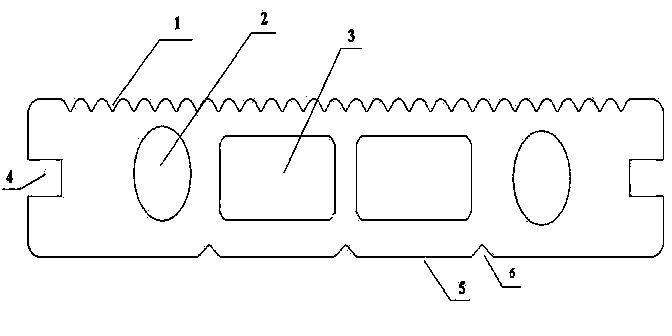

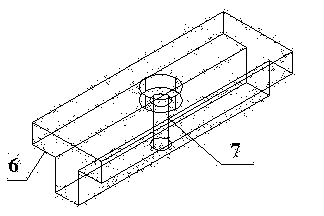

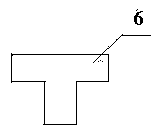

[0021] see figure 1 , figure 2 and image 3 As shown, the upper surface 1 of the present invention is provided with wavy grooves. When laying the upper surface 1, if the upper surface 1 is laid on it, the wavy grooves can play an anti-slip effect, and the anti-slip effect is good. 1 is laid below, the effect of the wave-shaped groove is to keep the plank road wood in a dry state; the lower surface 5 is provided with a surface groove, if the lower surface 5 is laid on the lower part, the surface groove plays the role of air circulation, on the contrary, If the lower surface 5 is laid on the upper part, the grooves on the surface and the wood grain patterns on the surface play a role of anti-slip.

[0022] The cross-section of the wood-plastic plank road is rectangular, and a circular hole 2 and a square hole 3 are arranged in the rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com