Roller shutter having two counter-rotating blinds and handling head equipped therewith for handling articles

A closed device, shutter-type technology, applied in the direction of transportation and packaging, stacking of objects, destacking of objects, etc., to achieve the effect of wide loading and unloading openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The illustrated embodiments are only examples, as can be constructed of the louvered closure according to the invention or the louvered head according to the invention, and do not constitute any decisive restrictions.

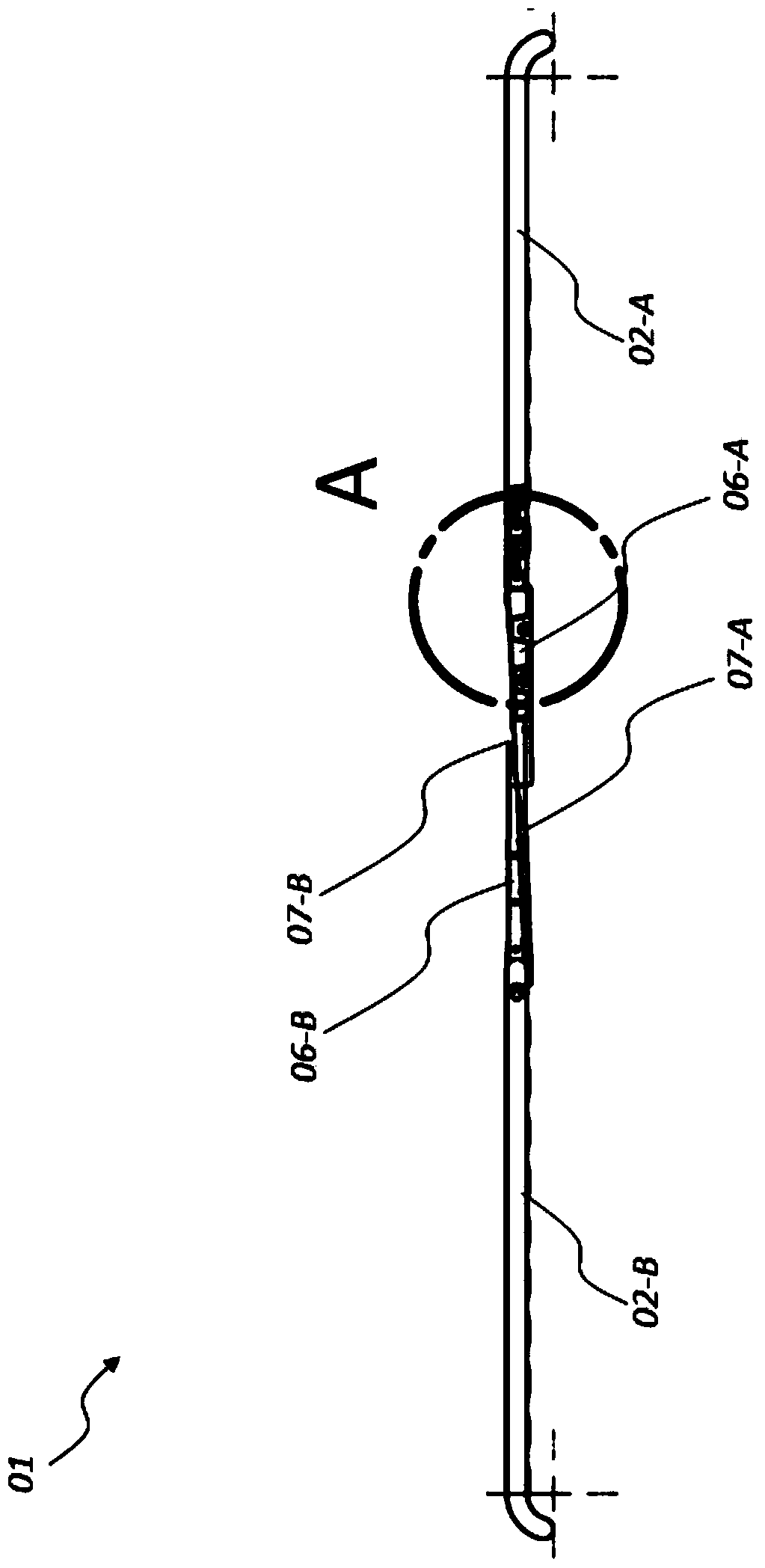

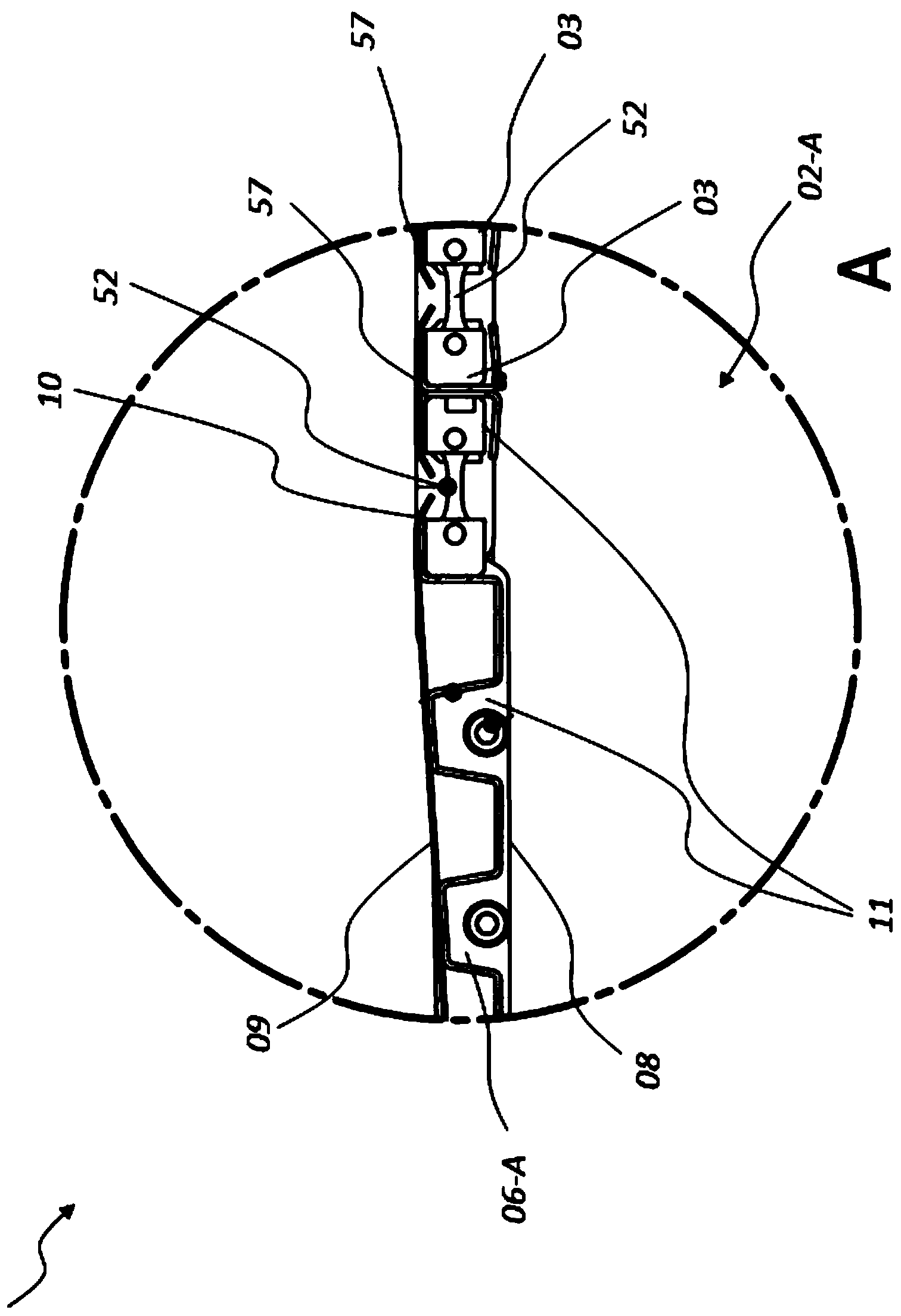

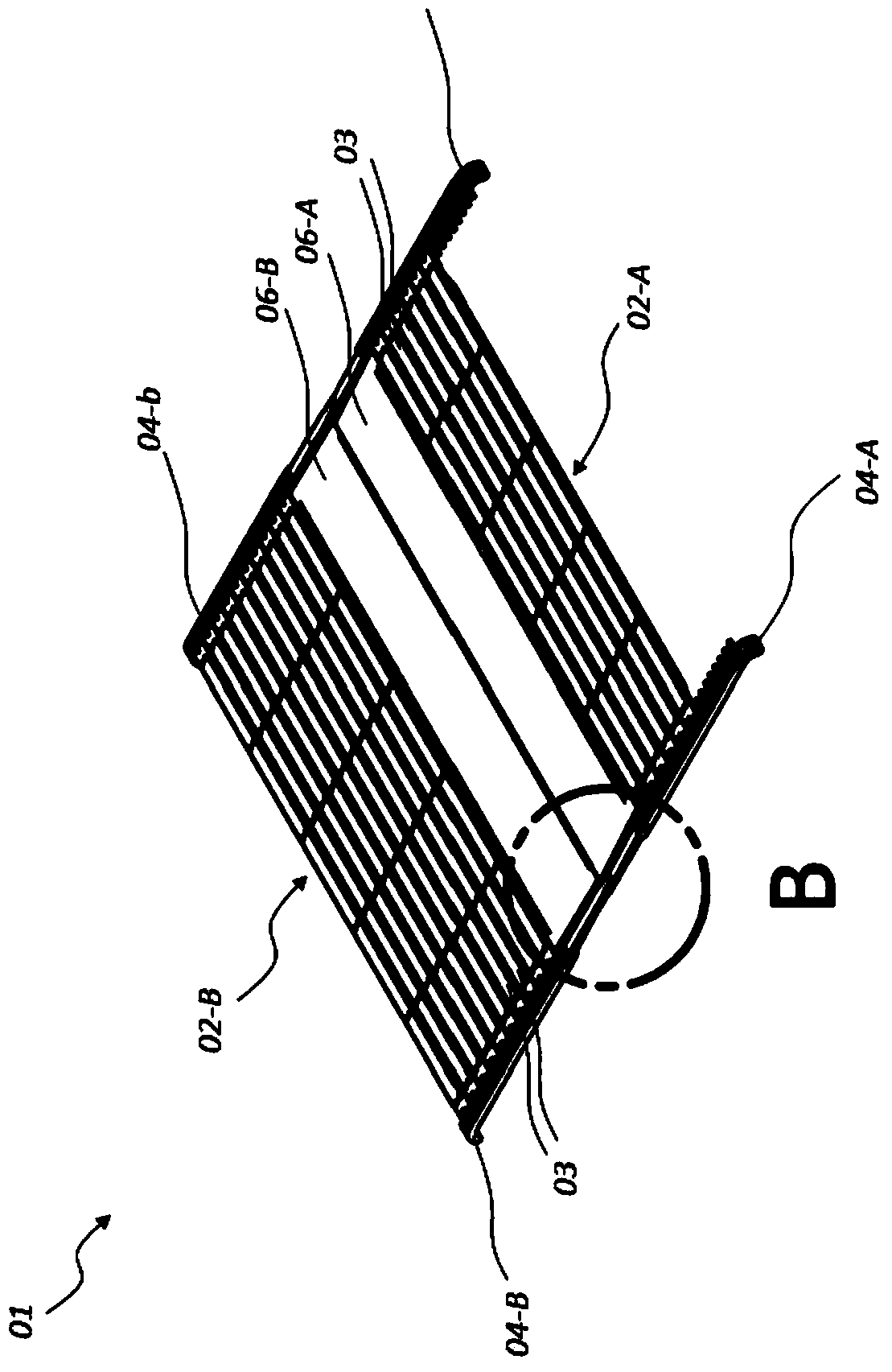

[0088] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 9 The louver type closure device 01 shown in full or in part basically comprises at least one pair of guide devices 04-A, 04-a, 04-B, 04-b arranged opposite to each other and spaced apart from each other and two guide devices that can pass along the The devices 04-A, 04-a, 04-B, 04-b predetermine the guide rails to move the shutters 02-A, 02-B from the closed position into the open position and vice versa.

[0089] Both shutters 02 -A, 02B can be associated with the same pair of guide devices 04 arranged opposite one another and spaced apart.

[0090] Alternatively, as in figure 2 and Figure 5 Recognizably shown in , each of the shutters 02-A, 02-B can be equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com