Light truck tire

A tire and light-weight technology, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of non-wear resistance and poor load resistance of radial tires, so as to improve wear resistance and improve Improve driving comfort and load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

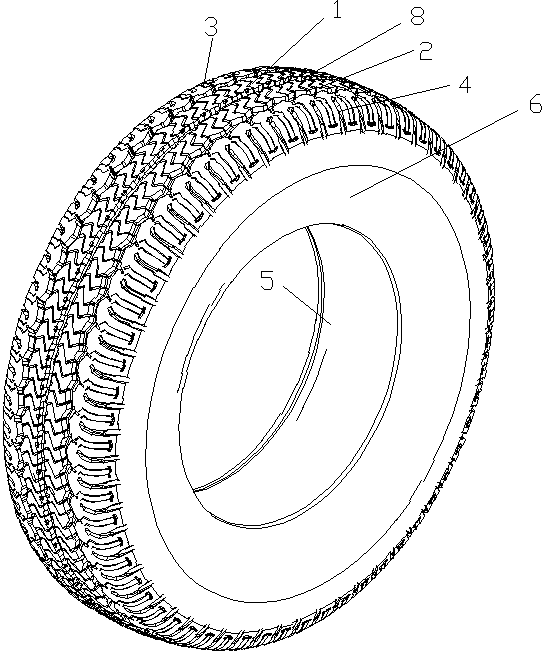

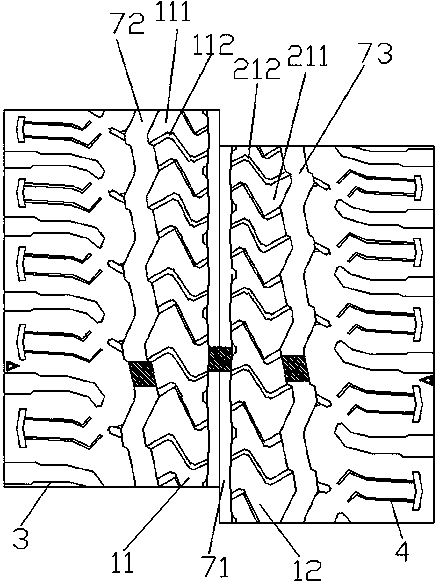

[0054] see figure 1 and figure 2 , as shown in the legend therein, a light-duty truck tire includes a tire body, the tire body has a tread, and the tread includes a crown, a sidewall and a shoulder, and the crown is along the centerline of the tire 8 is divided into a left crown 1 and a right crown 2, and the above-mentioned sidewalls include a left sidewall 5 arranged perpendicular to the left crown 1 and a right sidewall 6 arranged perpendicular to the right crown 2; the above-mentioned shoulders including a left shoulder 3 connecting the left sidewall 5 to the left crown 1 in a smooth transition and a right shoulder 4 connecting the right sidewall 6 to the right crown 2 in a smooth transition,

[0055] The left crown 1 is provided with a left crown continuous pattern block sequence 11 extending along its circumferential direction, and the left crown continuous pattern block sequence 11 includes a plurality of zigzag left crown pattern blocks arranged at intervals along it...

Embodiment 2

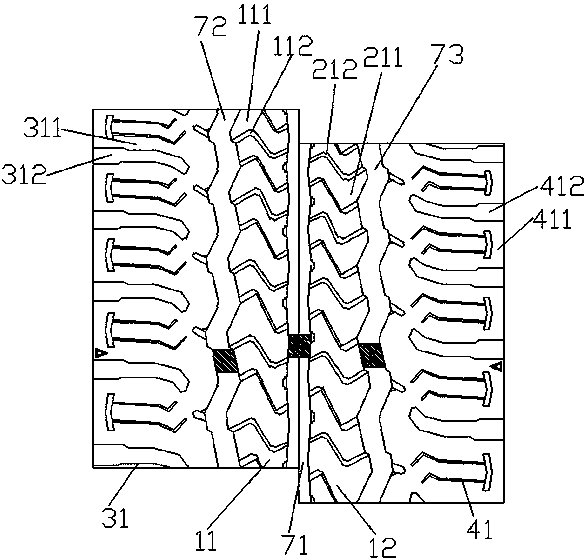

[0068] see figure 1 and image 3 , as shown in the legend therein, the rest are the same as in Example 1, the difference is that

[0069] The left shoulder 3 is provided with a left shoulder continuous pattern block sequence 31 extending along its circumferential direction, and the left shoulder continuous pattern block sequence 31 includes a plurality of zigzag left shoulder pattern blocks arranged at intervals along its circumferential direction 311;

[0070] The right shoulder 4 is provided with a right shoulder continuous pattern block sequence 41 extending along its circumferential direction, and the right shoulder continuous pattern block sequence 41 includes a plurality of zigzag right shoulder pattern blocks arranged at intervals along its circumferential direction 411.

[0071] The zigzag left shoulder pattern blocks 311 and the zigzag right shoulder pattern blocks 411 are oppositely arranged and staggered.

[0072] A zigzagging first left shoulder transverse groo...

Embodiment 3

[0077] see figure 1 and Figure 4 , as shown in the legend therein, the rest is the same as that of Embodiment 2, the difference is that two zigzag-shaped second tires extending axially along the left shoulder 3 are provided on the zigzag-shaped left shoulder block 311. Left shoulder lateral groove 3131;

[0078] A left shoulder longitudinal groove 3132 extending along the circumferential direction of the left shoulder 3 is communicated with the outer side of the zigzag second left shoulder transverse groove 3131;

[0079] The zigzag right shoulder block 411 is also provided with at least two zigzag second right shoulder transverse grooves 4141 axially extending along the right shoulder 4;

[0080] A right shoulder longitudinal groove 4142 extending along the circumferential direction of the right shoulder 4 is communicated with the outer side of the zigzagging second right shoulder transverse groove 4141 .

[0081] Both the second zigzag left shoulder lateral groove 3131 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com