Cooling and setting device and method for producing stone paper wallpaper base material

A technology of cooling and shaping and cooling device, which is applied in the field of building decoration materials, can solve the problems of poor film thickness uniformity, large width deviation, and easy wrinkling, so as to improve smoothness, product quality and yield, and ensure absolute The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

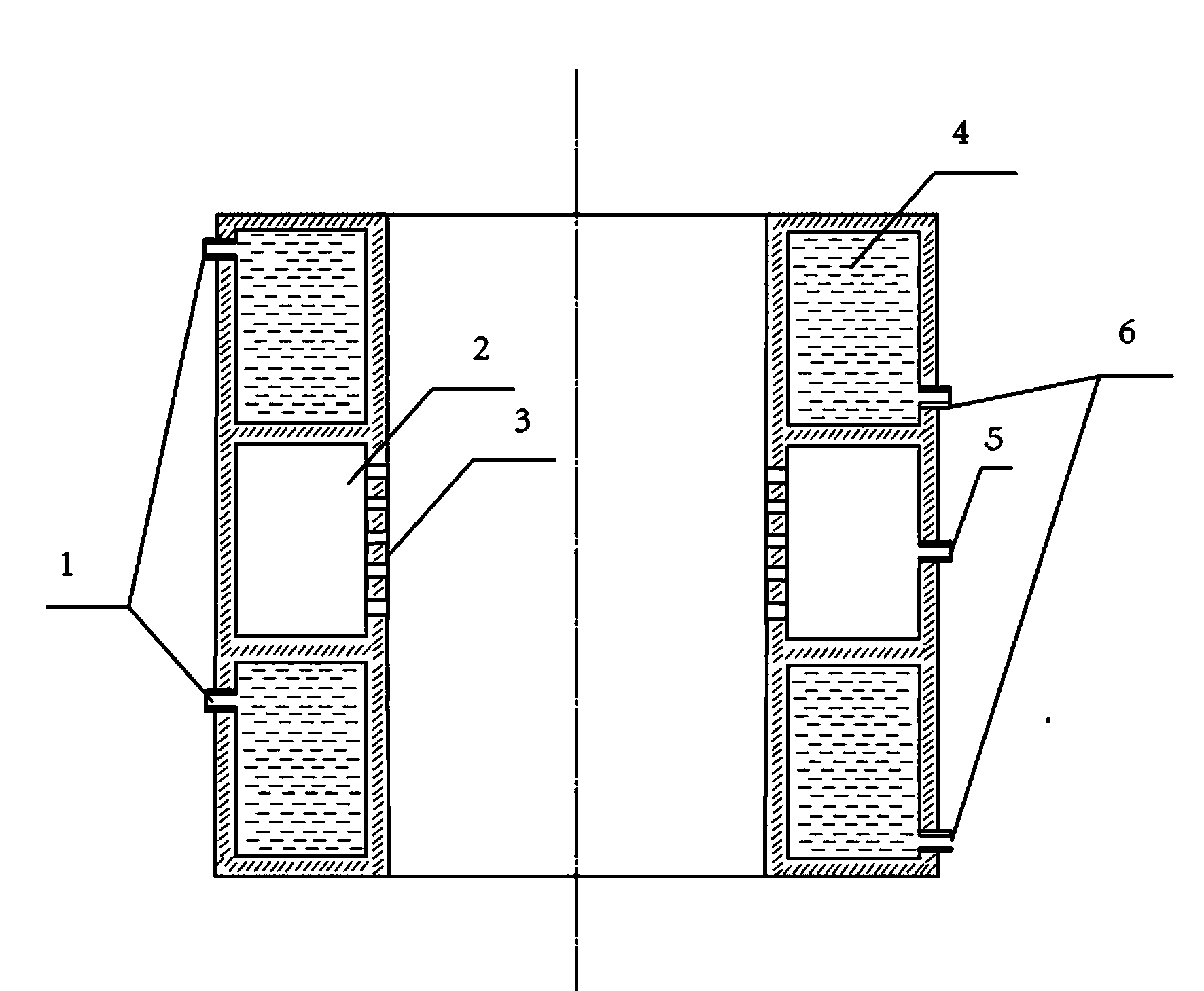

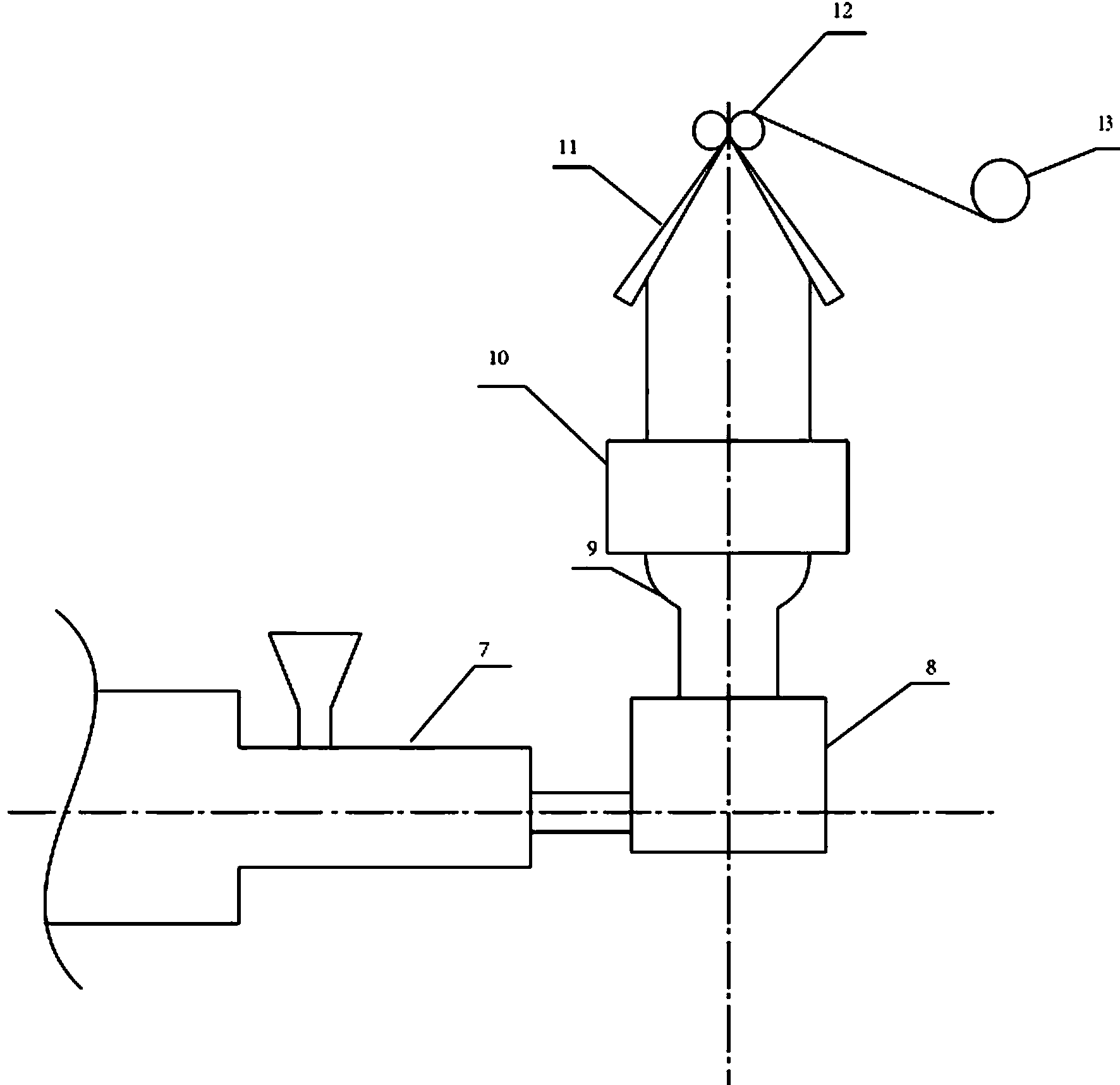

[0023] A cooling and sizing device for the production of stone paper wallpaper substrates, which consists of a vacuum sizing device 2 and two cooling devices 4 . The two cooling devices 4 are two closed annular water or oil jackets, the purpose of which is to preliminarily cool the high-temperature molten wallpaper base blank. The vacuum sizing device 2 is an annular closed chamber, the purpose of which is to tightly adhere the high-temperature molten wallpaper substrate parison to the inner wall of the annular closed chamber due to the vacuum negative pressure. The two annular water or oil jackets are respectively connected to both ends of the annular closed chamber to form an integral structure. The annular water or oil jacket is provided with four evenly distributed water (oil) inlets 6 and water (oil) outlets 1, and circulating cooling water (oil) can pass through the inside. The annular closed chamber is provided with an interface 5 connected with a vacuum machine, and t...

Embodiment 2

[0026] A cooling and sizing device for the production of stone paper wallpaper substrates, which consists of a vacuum sizing device 2 and two cooling devices 4 . The two cooling devices 4 are two closed annular water or oil jackets, the purpose of which is to preliminarily cool the high-temperature molten wallpaper base blank. The vacuum sizing device 2 is an annular closed chamber, the purpose of which is to tightly adhere the high-temperature molten wallpaper substrate parison to the inner wall of the annular closed chamber due to the vacuum negative pressure. The two annular water or oil jackets are respectively connected to both ends of the annular closed chamber to form an integral structure. The annular water or oil jacket is provided with eight evenly distributed water (oil) inlets 6 and water (oil) outlets 1, and circulating cooling water (oil) can pass through the inside. The annular closed chamber is provided with an interface 5 connected with a vacuum machine, and ...

Embodiment 3

[0028]A cooling and sizing device for the production of stone paper wallpaper substrates, which consists of a vacuum sizing device 2 and two cooling devices 4 . The two cooling devices 4 are two closed annular water or oil jackets, the purpose of which is to preliminarily cool the high-temperature molten wallpaper base blank. The vacuum sizing device 2 is an annular closed chamber, the purpose of which is to tightly adhere the high-temperature molten wallpaper substrate parison to the inner wall of the annular closed chamber due to the vacuum negative pressure. The two annular water or oil jackets are respectively connected to both ends of the annular closed chamber to form an integral structure. The annular water or oil jacket is provided with two evenly distributed water (oil) inlets 6 and water (oil) outlets 1, and circulating cooling water (oil) can pass through the inside. The annular closed chamber is provided with an interface 5 connected with a vacuum machine, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com