Cutter reciprocating type granulation machine

A granulator and reciprocating technology, which is applied in the direction of making medicines into special physical or ingestible devices, etc., can solve the problems of particle shape, size and packaging process that cannot be packaged, and granule drug content is different, so as to ensure that the granules contain medicine Quantity, convenient packaging, regular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

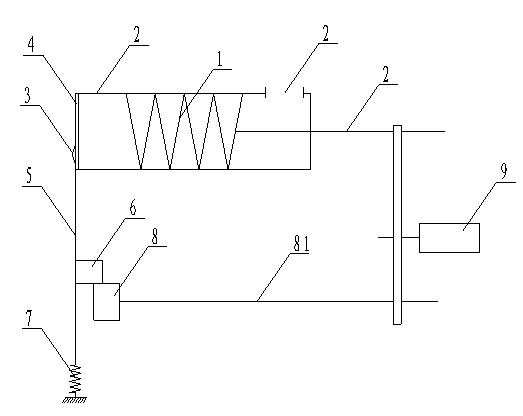

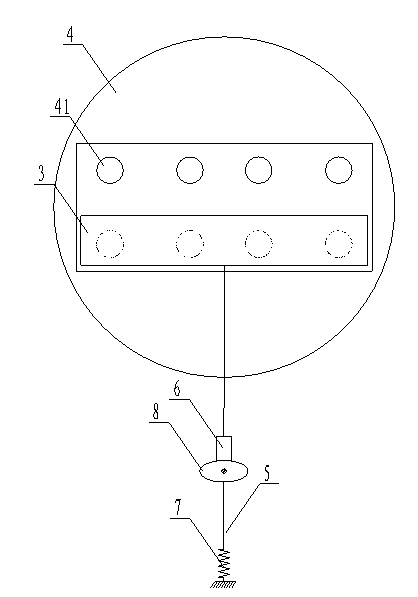

[0017] Such as figure 1 and figure 2 The cutter reciprocating granulator shown includes an auger 1, an auger installation cylinder 2, a double-edged cutter 3, a sieve plate 4, a push rod 5, a push block 6, a return spring 7, and an oval push block 8 and motor 9,

[0018] The auger 1 is installed in the auger installation barrel 2, and the rear end is connected with the motor 9 through the auger shaft 11,

[0019] The sieve plate 4 is installed at the front end of the auger installation cylinder 2, and the sieve plate 4 is provided with two rows of through holes 41 up and down.

[0020] The knife surface of the double-edged cutter 3 is set close to the surface of the sieve plate 4, and its double edges are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com