Composite calender fermentation device with cleaning function

A technology of fermentation device and calender, which is applied in the fields of dough fermenter, baking, food science, etc., can solve the problems of blocked sight of the staff, the quality and influence of falling noodles, and achieves good scraping effect, guarantees normal work, The effect of saving space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

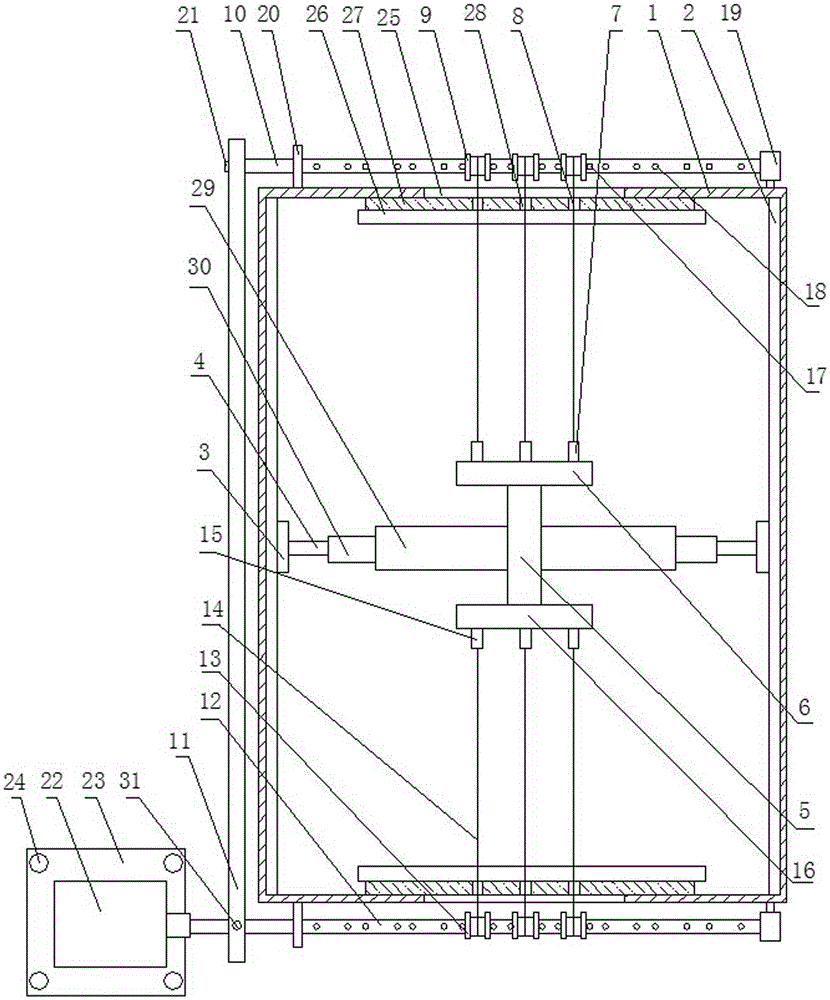

Embodiment 1

[0022] A compound calender fermentation device with a cleaning function, which consists of: a fermentation tank 1, a glass wiper, a telescopic rod, and a rotating shaft, and the fermentation tank 1 is connected to the glass wiper through a connecting piece; The connecting piece includes a slideway 2, the slideway 2 is connected to the slider 3, the slider 3 is connected to the telescopic rod, and the telescopic rod is connected to the handle 5 of the glass wiper, The top scraper 6 of the glass wiper is fixedly connected with 3-5 top connecting columns 7, the top connecting columns 7 are connected to the top pulling wire 8, and the top pulling wire 8 is connected to the top pulling spool 9 , the top traction spool 9 is connected to the No. 1 rotating rod 10, the No. 1 rotating rod 10 is connected to the connecting rod 11, the connecting rod 11 is connected to the No. 2 rotating rod 12, and the No. 12 rotating rod is connected Connect the bottom pulling spool 13, the bottom pull...

Embodiment 2

[0024] In the compound calender fermentation device with cleaning function described in Example 1, a group of through holes 17 are respectively opened on the No. 1 rotating rod 10 and the No. 2 rotating rod 12, and the through holes 17 pass through Through the positioning rod 18, the top pulling spool 9 and the bottom pulling spool 13 are connected between the positioning rods 18, and one end of the second rotating rod 12 and one end of the rotating rod one 10 are respectively A rotating rod sleeve 19 is connected, and the rotating rod sleeve 19 is connected to one end of the fermentation tank 1, and the other end of the second rotating rod 12 is connected to the other end of the first rotating rod 10 respectively. There is a connection sleeve 20, and the connection sleeve 20 is connected to the other end of the fermentation tank 1. A group of through holes on the rotating rod can make the position of the traction shaft adjustable, so that the scraping area of the glass wipe...

Embodiment 3

[0026] In the compound calender fermentation device with cleaning function described in Example 1, the connecting rod 11 is connected to the other end of the first rotating rod 10 and the second rotating rod 12, and the connecting rod 11 is connected to the No. 1 fixed shaft 21, and the No. 1 fixed shaft 21 is fixedly connected to the bottom end of the connecting rod 11, and the top end of the connecting rod 11 is connected to the No. 1 rotating rod 10 described above. The lower end of the rod 11 is connected to the second rotating rod 12 through the second fixed shaft 31, and the bottom surface of the second rotating rod 12 is connected to the forward and reverse motor 22 to be connected. Ensure clear structure and high usability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com