High-pressure pin insulator with fixed wire fitting

A technology of high-voltage needles and insulators, applied in the direction of needle insulators, etc., can solve the problems of strong vibration, instability, and wear of contact parts, and achieve the effects of avoiding friction and cutting, simple and reliable structure, and high locking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

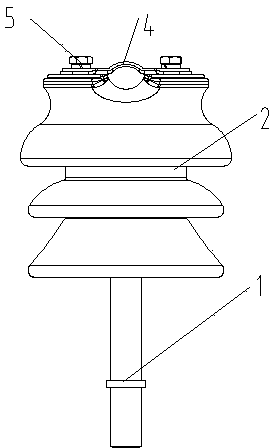

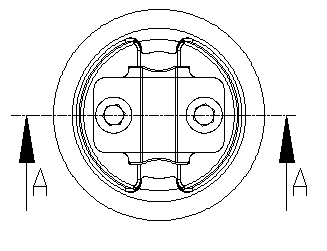

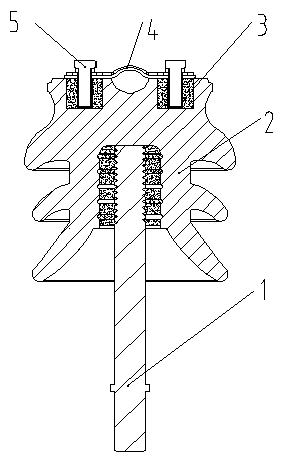

[0022] Such as Figure 1~3 As shown, a high-voltage pin insulator with its own fixed wire fittings includes a porcelain body 2 and fixed wire fittings. The fixed wire fittings are two threaded zinc sleeves 3 arranged on the upper part of the porcelain body 2. The thread The zinc sleeve 3 is provided with a wire pressing plate 4, and the wire pressing plate 4 is locked by a stainless steel bolt 5. A steel foot 1 is provided at the lower part of the porcelain body 2, and one end of the steel foot 1 is inserted into the interior of the porcelain body 2, and the other end is inserted into the porcelain body 2. Installed on the cross arm of the utility pole.

[0023] In this embodiment, in order to make the threaded zinc sleeve 3, the steel foot 1 and the porcelain body 2 form a system, so that it has the functions of support, insulation and fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com