An explosion-proof test box for detecting gas alarm

A technology of explosion-proof test box and gas alarm, which is applied in the direction of instruments, instrument parts, electrical program control, etc., can solve the problems of many human interference factors, unsafe hidden dangers, and inconvenient operation, so as to improve the detection quality and efficiency, Compact structure and reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

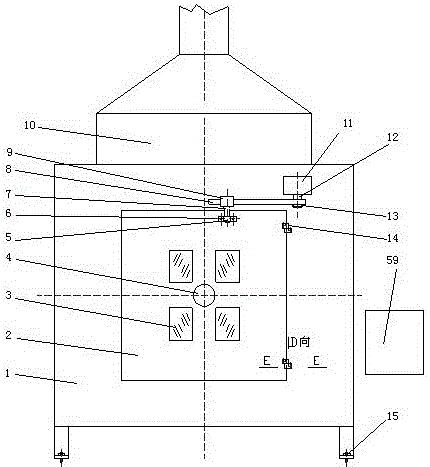

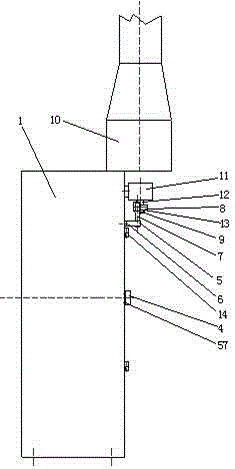

[0026] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a box body 1 in which a box door 2 is installed through a door hinge 14. A shaft seat 5 is installed on the box door 2 through a fixing bolt 6, and a rotating shaft 7 is inserted in the shaft seat 5. The upper part of the rotating shaft 7 is welded with a Sliding sleeve 9, a swing rod 8 is housed in the sliding sleeve 9, a swing rod stepping motor 11 is installed on the outer wall of the box body 1 above the box door 2 through fixing bolts, and the other end of the swing rod 8 is fixed on the swing rod stepping motor through a nut 13. On the motor shaft 12 of motor 11; Stepper motor 4 is installed in the middle position of box door 2 outer sides, and the motor shaft 28 of stepper motor 4 is inserted in the box door 2 interlayers, and is fixed with rotating on the inner side surface of box door 2 interlayers. Disc 27; The push rod 17 that connects slide shaft 22 one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com