A 0.532 micron and 1.064 micron frequency doubling anti-reflection coating for large curvature lens surfaces

A technology of large-curvature lens and anti-reflection coating, applied in optical components, optics, instruments, etc., can solve problems such as damage and increase system noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

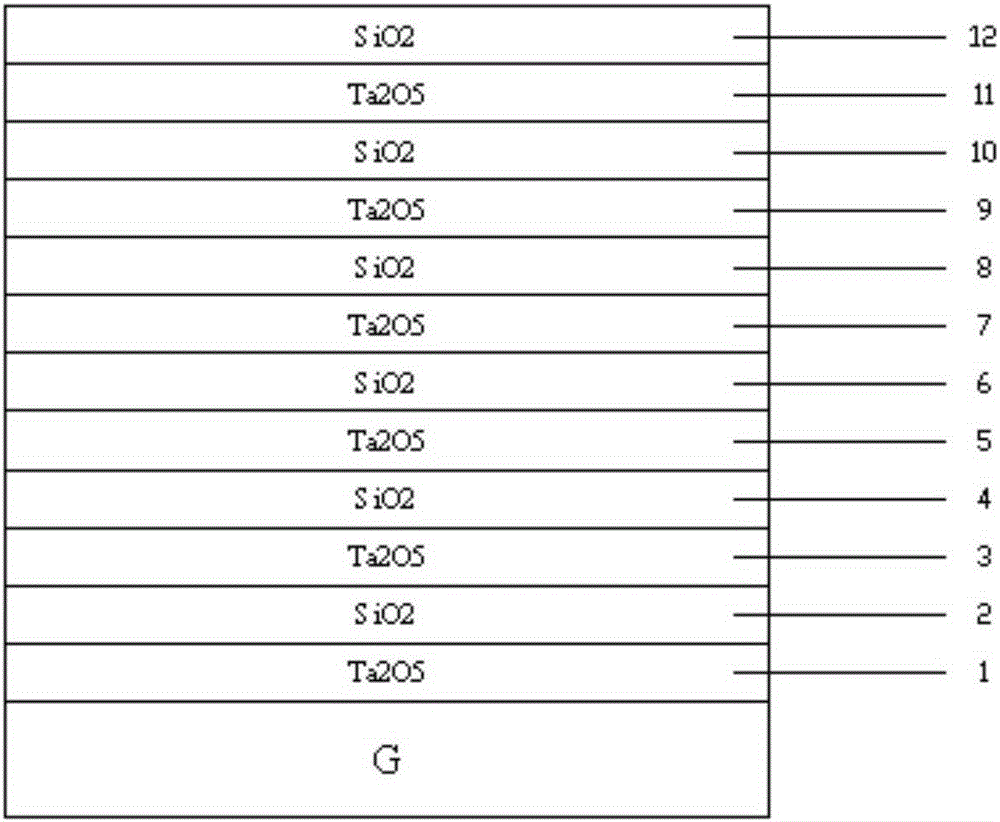

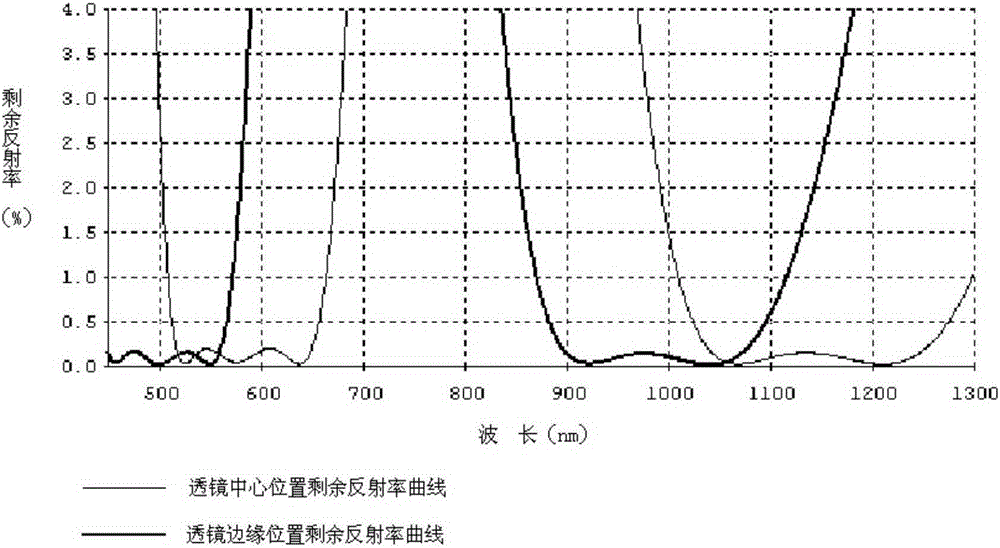

[0031] Embodiment 1 selects K9 glass substrate for use, Ta 2 o 5 When the refractive index is 1.996, it is the standard Ta 2 o 5 Refractive index, the ratio of the radius of curvature of the lens to the aperture is equal to 1. At this time, the lens is a large curvature lens, and the first to twelfth film layers 1 to 12 are plated in sequence, and the thicknesses of the first to twelfth film layers are 11.8nm respectively , 34.5nm, 128.5nm, 15.2nm, 48.3nm, 30.8nm, 65.1nm, 189.9nm, 131nm, 47.9nm, 39.8nm, 130.2nm. After testing, the residual reflectance curves of the lens edge position and the lens center point position at 0.532 μm and 1.064 μm wavelengths were respectively obtained (see image 3 ), the residual reflectivity at the lens edge position at 0.532 μm wavelength = 0.137%, and the residual reflectivity at 1.064 μm wavelength = 0.085%; the residual reflectivity at the lens center position at 0.532 μm wavelength = 0.093%, at 1.064 μm Residual reflectivity at waveleng...

Embodiment 2

[0032] Embodiment 2 selects K9 glass substrate for use, Ta 2 o 5 When the refractive index is 1.996, it is the standard Ta 2 o 5 Refractive index, the ratio of the radius of curvature of the lens to the aperture is equal to 1.5. At this time, the lens is a large curvature lens. The first to twelfth film layers 1 to 12 are plated in sequence, and the thicknesses of the first to twelfth film layers are respectively 11.8nm , 34.5nm, 128.5nm, 15.2nm, 48.3nm, 30.8nm, 65.1nm, 189.9nm, 131nm, 47.9nm, 39.8nm, 130.2nm. After testing, the residual reflectance curves of the lens edge position and the lens center point position at 0.532 μm and 1.064 μm wavelengths were respectively obtained (see Figure 4 ), the residual reflectivity at the lens edge position at 0.532 μm wavelength=0.073%, the residual reflectivity at 1.064 μm wavelength=0.146%; the residual reflectivity at the lens center position at 0.532 μm wavelength=0.093%, at 1.064 μm Residual reflectivity at wavelength = 0.028%...

Embodiment 3

[0033] Embodiment 3 selects K9 glass substrate for use, Ta 2 o 5 When the refractive index is 1.996, it is the standard Ta 2 o 5 Refractive index, the ratio of the radius of curvature of the lens to the aperture is equal to 2. At this time, the lens is a large curvature lens. The first to twelfth film layers 1 to 12 are plated in sequence, and the thickness of the first to twelfth film layers are 11.8nm respectively. , 34.5nm, 128.5nm, 15.2nm, 48.3nm, 30.8nm, 65.1nm, 189.9nm, 131nm, 47.9nm, 39.8nm, 130.2nm. After testing, the residual reflectance curves of the lens edge position and the lens center point position at 0.532 μm and 1.064 μm wavelengths were respectively obtained (see Figure 5 ), the residual reflectivity at the lens edge position at 0.532 μm wavelength=0.184%, the residual reflectivity at 1.064 μm wavelength=0.097%; the residual reflectivity at the lens center position at 0.532 μm wavelength=0.093%, at 1.064 μm Residual reflectivity at wavelength = 0.028%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com