Fan noise and resonance measurement equipment

A resonance measurement and fan technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of uneven distribution of axial velocity, narrow-frequency abnormal sound, and high requirements of the test environment, and achieve anti-interference Good, highly recognizable, low test environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

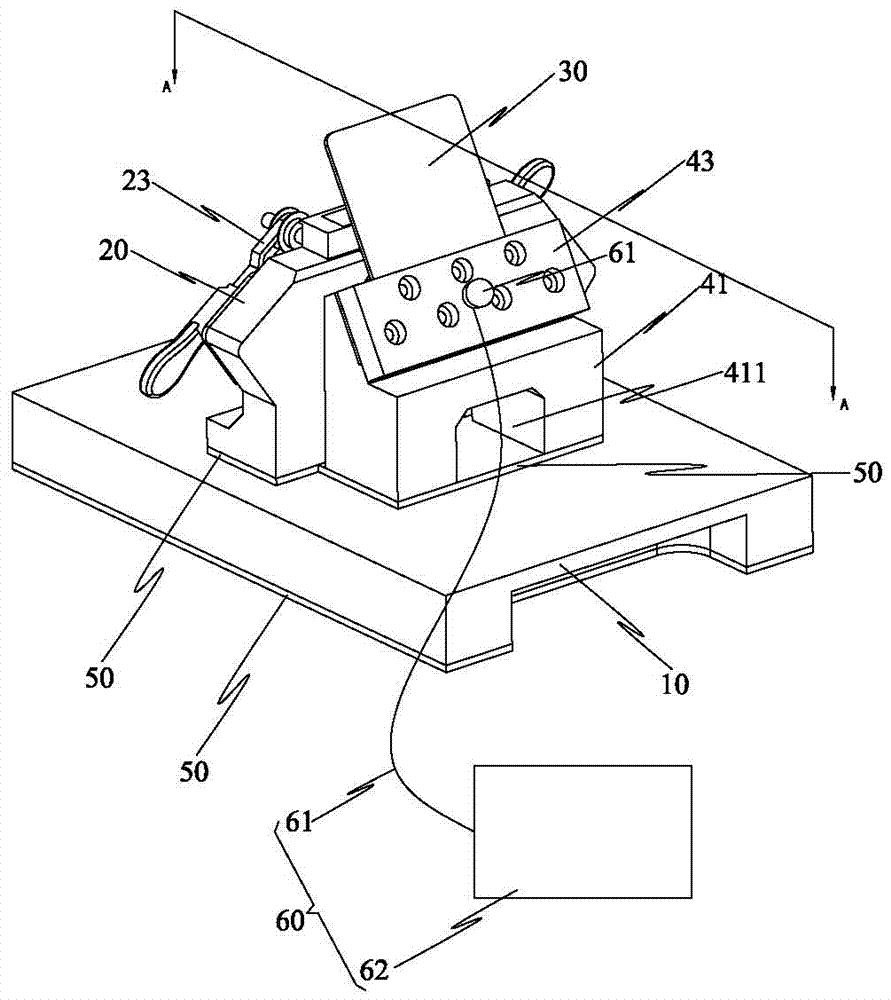

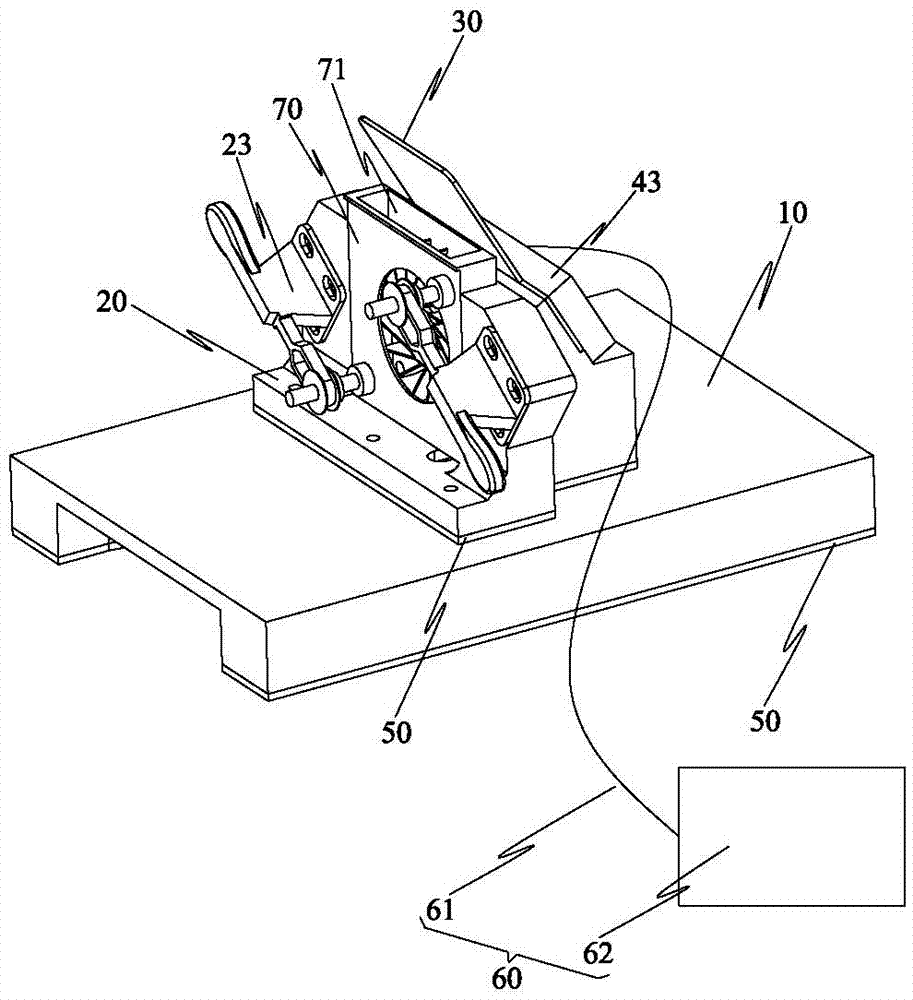

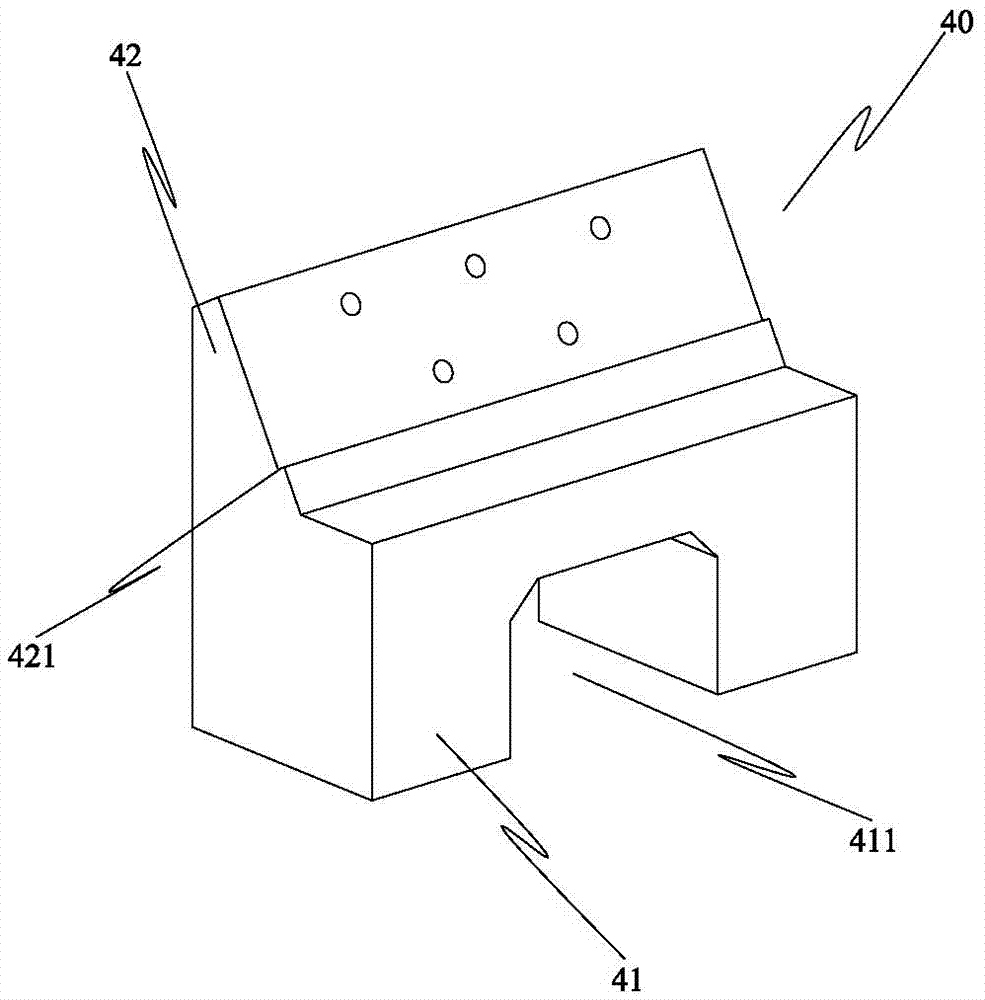

[0036] The present invention as Figure 1 to Figure 6 As shown, a fan noise resonance measurement device includes a base 10, a fan fixing base 20, a resonator 30, a resonator fixing base 40, and a vibration signal pickup and analysis device 60, wherein:

[0037] The bottom of the base 10 is laid with a vibration isolation pad 50, which is in the shape of a flat plate. The above-mentioned resonator holder 40 and fan holder 20 are installed independently on the base 10 with a gap between them, and are fixed on the resonator. Vibration-isolating pads 50 are respectively disposed under the seat 40 and the fan fixing seat 20 .

[0038] The fan fixing seat 20 includes a base 21 and a support plate 22 arranged on the base 21. An embedding groove 221 for installing a fan is arranged on the support plate 22, and the fan outlet 71 is vertically embedded in the support plate 22. In the embedding groove 221, the embedding groove 221 has a round hole 2211 on one side close to the resonato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com