Reinforced unidirectional-blocking-eave bollard

A kind of bollard and enhanced technology, applied in the direction of shipping equipment, etc., can solve the problems of shrinkage, unreasonable bollard structure design, large material waste, etc., and achieve the effect of improving the mooring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

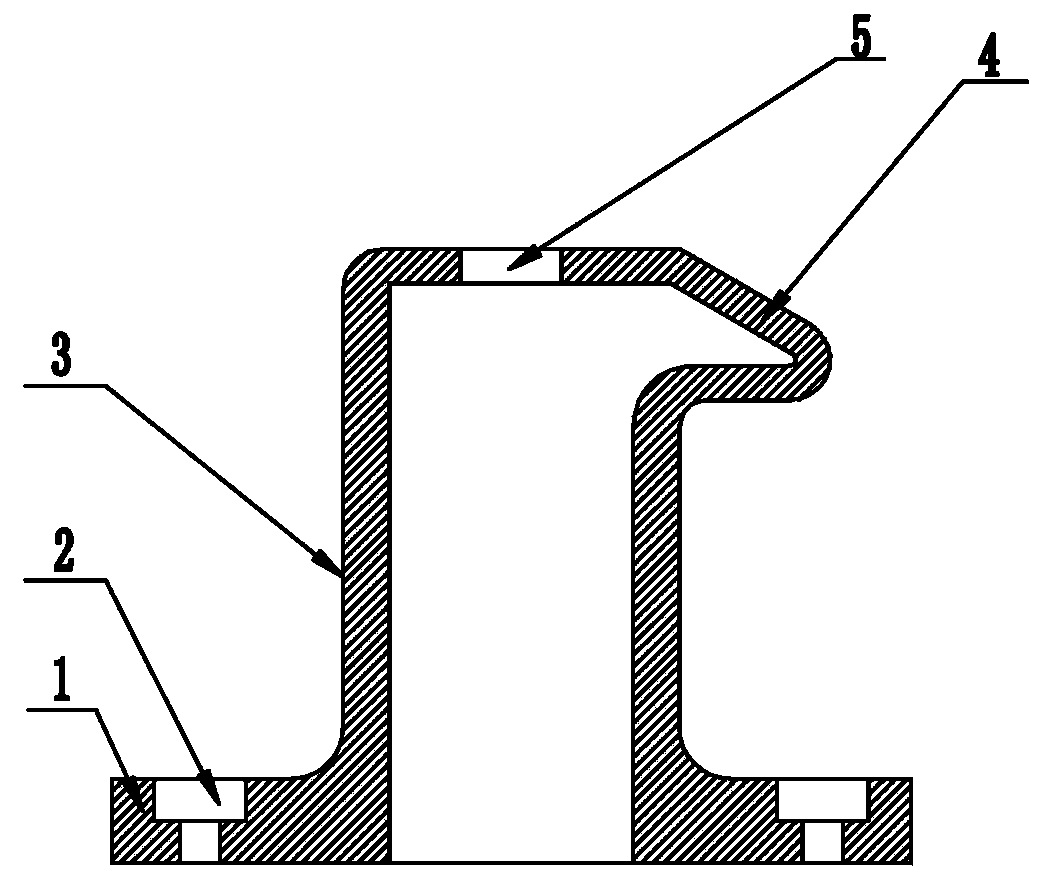

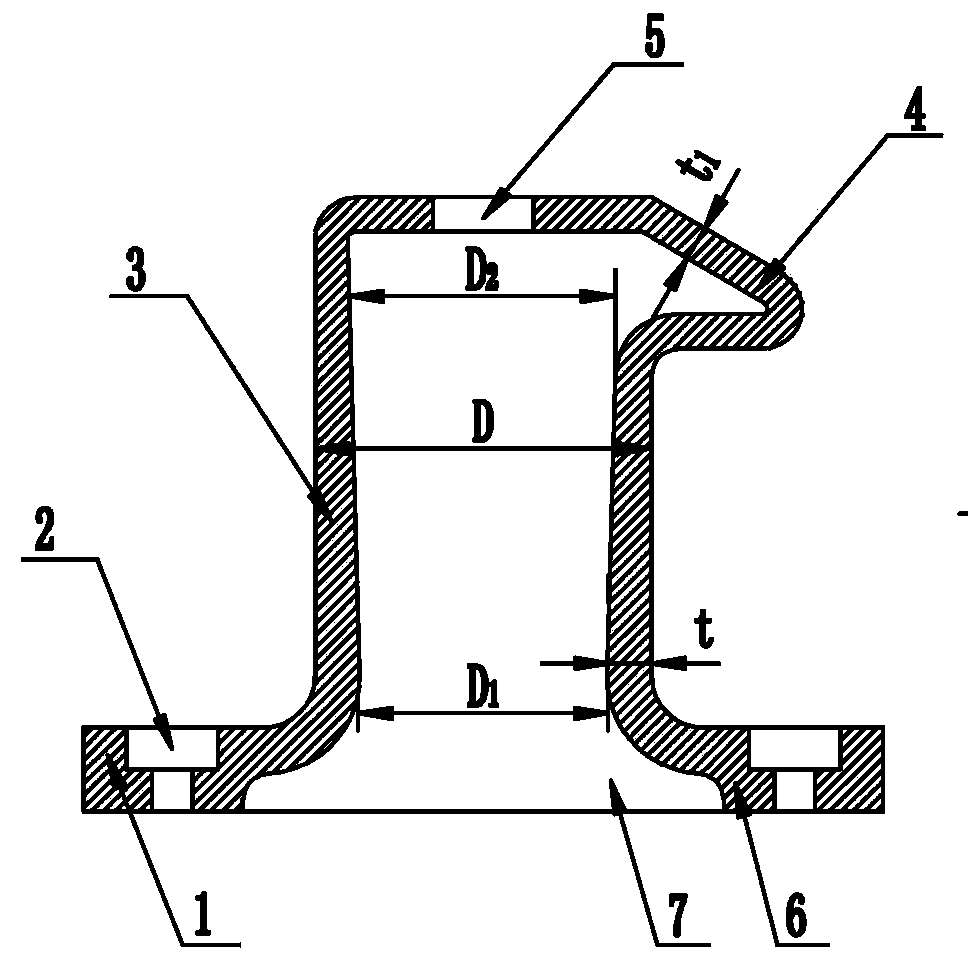

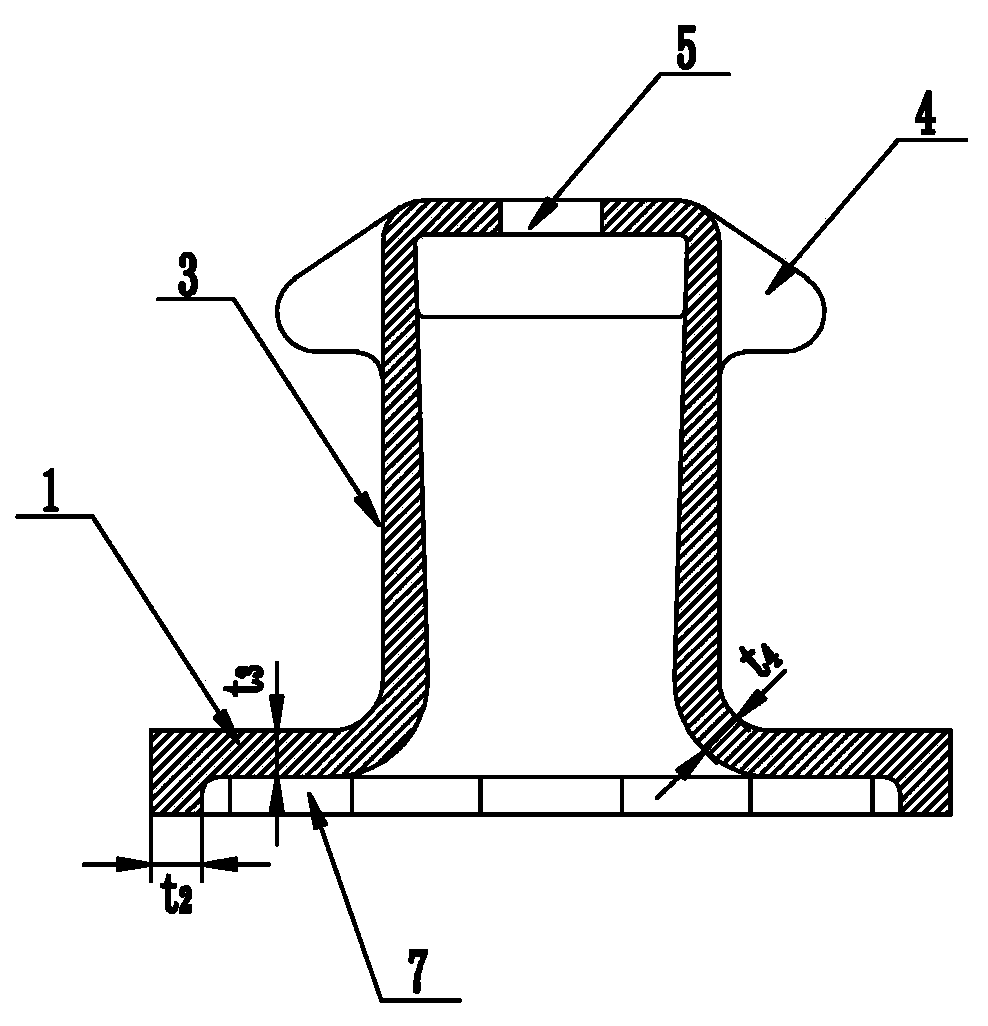

[0050] see figure 2—5. The present invention has a chassis 1, a column body 3 and a single-sided eaves 4. Several anchor bolt counterbores 2 are arranged on the chassis 1, and a top hole 5 is opened on the top of the single-sided eaves 4. The column body 3 And the single-sided retaining eaves 4 is a cavity structure, the design standard wall thickness of the column body 3 is t=30mm, then the wall thickness t1 of the single-sided retaining eaves 4 is 22.5mm, especially: the cavity of the column body 3 is a tapered cavity , the inner diameter of the lower port of the column body 3 cavity D1 = 250-60 = 190mm (the outer diameter of the column body D can be checked as 250mm by the standard), the inner diameter of the upper port of the column body 3 cavity D2 = 250-45 = 205mm; on the chassis 1 A cavity is provided to keep the top wall thickness t3=30mm of the chassis cavity 7, and the side wall thickness t2=30-35mm, specifically 35mm. The junction of the chassis cavity 7 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com