Sensing type flat panel cutting machine

A technology of flat cutting machine and sensor, which is applied in the cutting of textiles, papermaking, and textile materials, etc., which can solve problems such as failure to warn of failures, and achieve the effect of improving efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

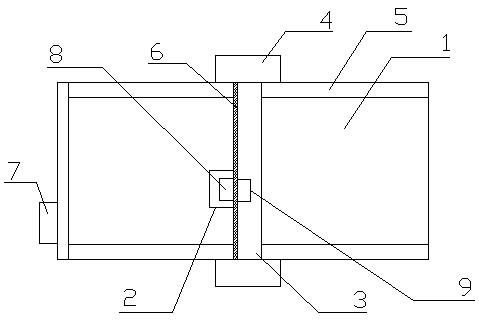

[0010] Such as figure 1 It is a schematic diagram of the structure of an induction flat cutting machine. An induction flat cutting machine includes a workbench 1, a moving block 2, a beam 3, a driving device 4, a transverse guide rail 5, a moving guide rail 6 and a control panel 7, and the workbench 1 There are horizontal guide rails 5 on both sides, and the driving device 4 is movably connected with the workbench 1 through the horizontal guide rails 5. A beam 3 is fixed in the middle of the driving device 4, and a moving guide rail 6 is arranged on the beam. The moving block 2 moves with the beam 3 through the moving guide rail 6. Connection, the side of the workbench 1 is also fixed with a control panel 7, the front end of the moving block 2 is provided with an inductor 8, the beam 3 is provided with an alarm 9, and the sensor 8 is connected to the alarm 9.

[0011] When the cutting machine starts to work, the driving device 4 is started to drive the beam 3 to move back and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com