Double-roller printer

A technology for printers and boxes, applied in printing devices, printing and other directions, can solve the problems of shortening the service life of the printer, high maintenance costs, waste of paper, etc., and achieve the effect of prolonging the service life, saving paper resources, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

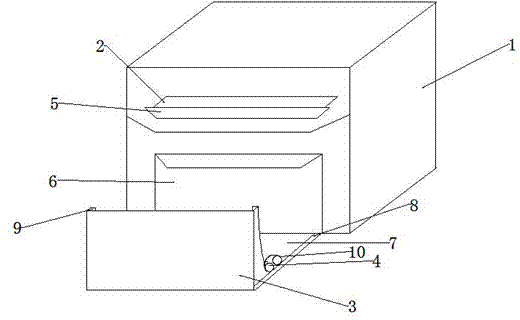

[0015] Example 1, see figure 1 , Fig. 3, a kind of double-roller printer, described printer comprises machine box body body 1, paper input device 6, paper output device 2, paper output tray 5, and described paper input device 6 is positioned at described machine box body 1 bottom , the opening of the paper feeding device 6 is rectangular, the paper feeding device 6 communicates with the inside of the machine box body 1, and the paper output device 2 is located at the top of the machine box body 1 and communicates with the inside of the machine box body 1, so The paper output tray 5 is located below the paper input device 6 , and the printer also includes a double-roller locking device, and the double-roller locking device is arranged outside the machine box body 1 .

[0016] The double-stick locking device mainly completes the process of transferring paper. In the process of transferring paper, the double-stick locking device ensures the smooth process of paper, thereby avoidi...

Embodiment 2

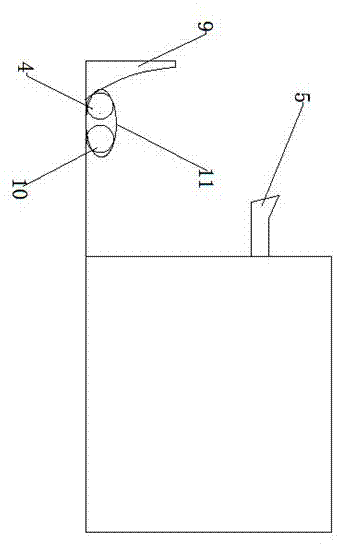

[0017] Example 2, see figure 1 , figure 2 , as an improvement of the present invention, the double-roller locking device includes a paper feeding roller 4 and a paper receiving roller 10 , and a conveying belt 11 is provided outside the paper feeding roller 4 and the paper receiving roller 10 .

[0018] The paper feeding roller transfers the paper to the paper receiving roller. Since the transmission is through the conveyor belt, the transmission in the middle is relatively stable, and the paper is not easy to be tilted, distorted, etc. during the transmission process.

[0019] The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0020] Example 3, see figure 1 , figure 2 , as an improvement of the present invention, the printer also includes a paper support board, the paper support board is composed of a vertical board 3 and a horizontal board 7, and the vertical board 3 and the horizontal board 7 are connected in an "L" shape, close to the vertical board The paper feed roller is installed at the position, and a motor is housed in the paper feed roller, and the motor drives the paper feed roller and then drives the paper receiving roller to move.

[0021] The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com