Yarn monitoring method

A technology for yarn and yarn quality, applied in the field of yarn extraction units, can solve the problems of time-consuming, defects, and yarn quality that does not meet the requirements, and achieve the effect of simplifying the selection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

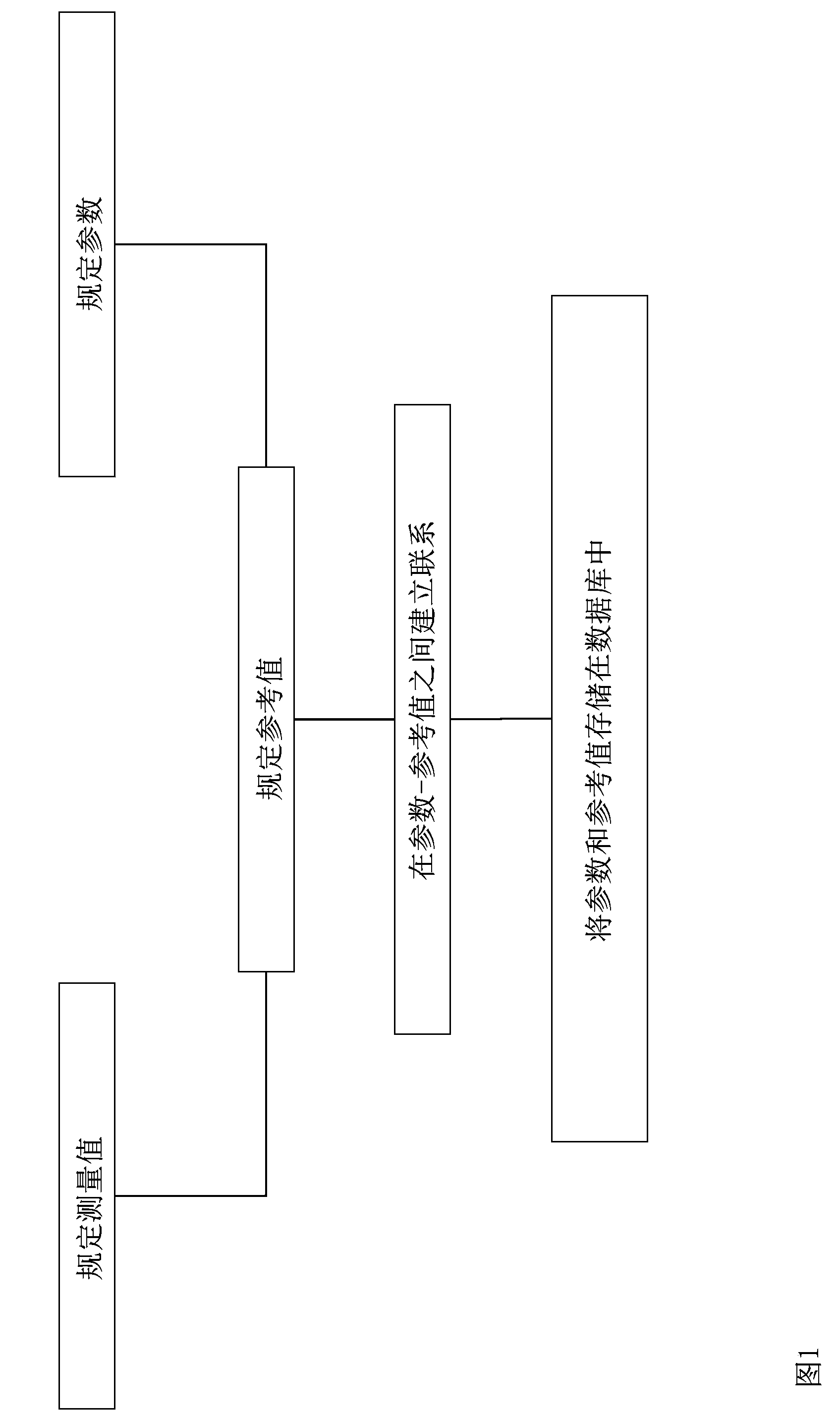

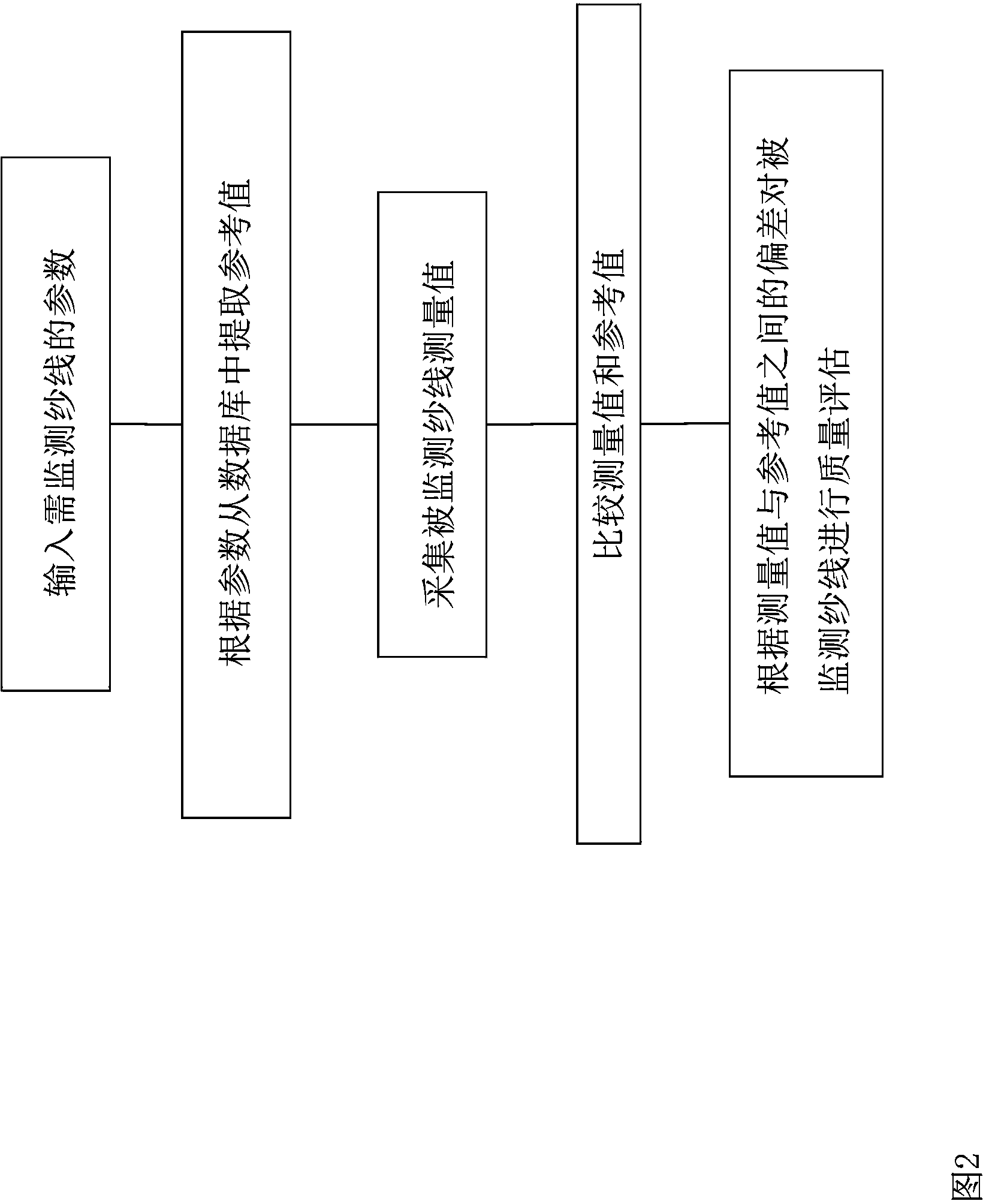

[0030] figure 1 The process of obtaining the required reference value according to the method of the present invention and storing it in the database is described in the form of a chart.

[0031] First, the measured value is defined, which is later collected and used as the basis for quality assessment when monitoring the yarn quality on the textile machine. For example, a current signal generated by a camera can be used as the measured value, and the camera can determine the geometry, in particular the width, of the projection produced by the yarn when it is illuminated by light. In this case the value of the measured value depends on the yarn thickness (=spatial extent perpendicular to the longitudinal axis of the yarn), ie the yarn thickness is monitored.

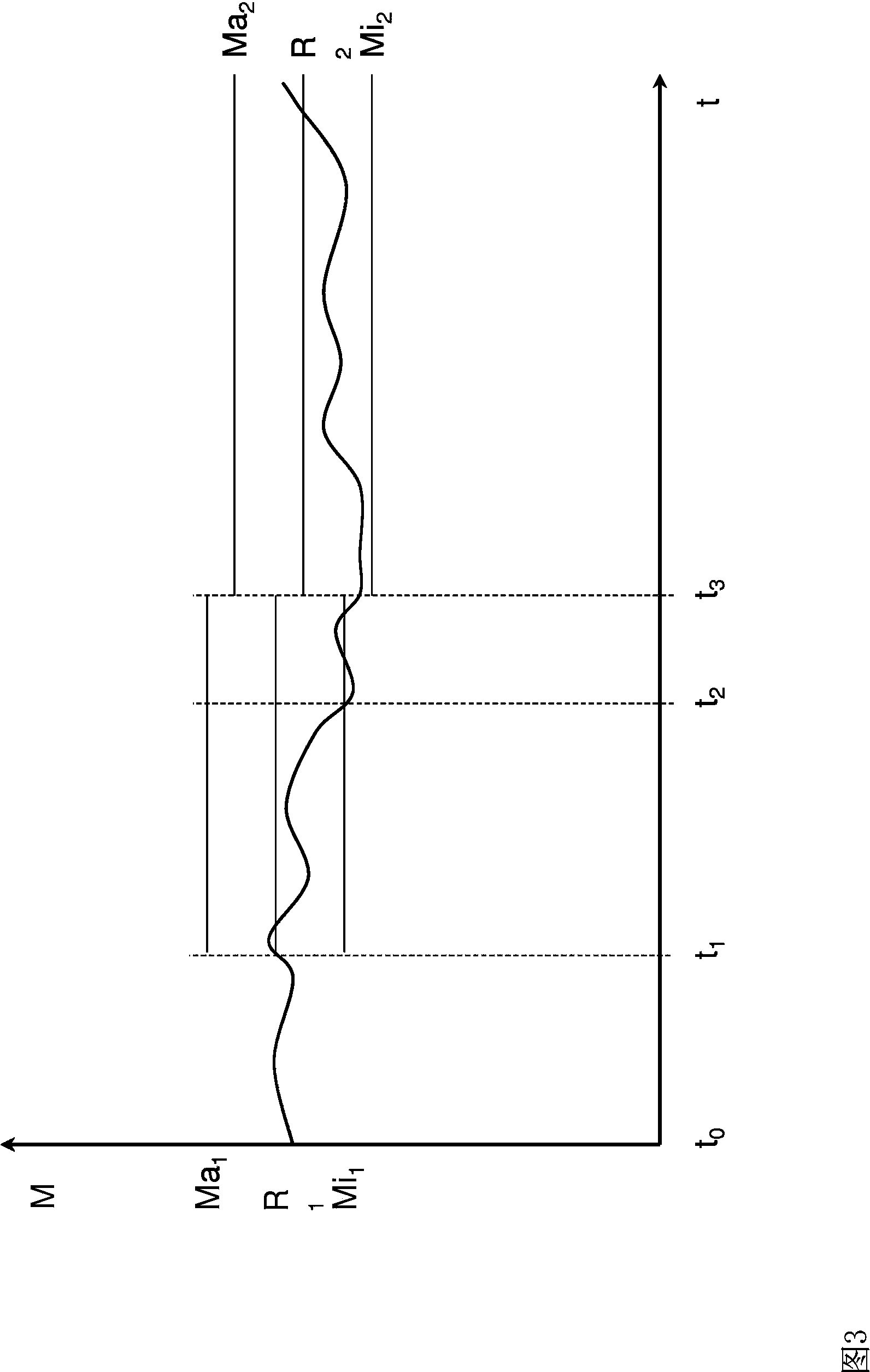

[0032] After specifying the measured value, a reference value is defined for the measured value. The reference value is the value that the measured value should have when the yarn quality is intact. Of course, as a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com