A device for remote operation and replacement of double-strand insulators for double-split lines

A double-split, insulator technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as inability to perform operations and inaccessibility of equipotential workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

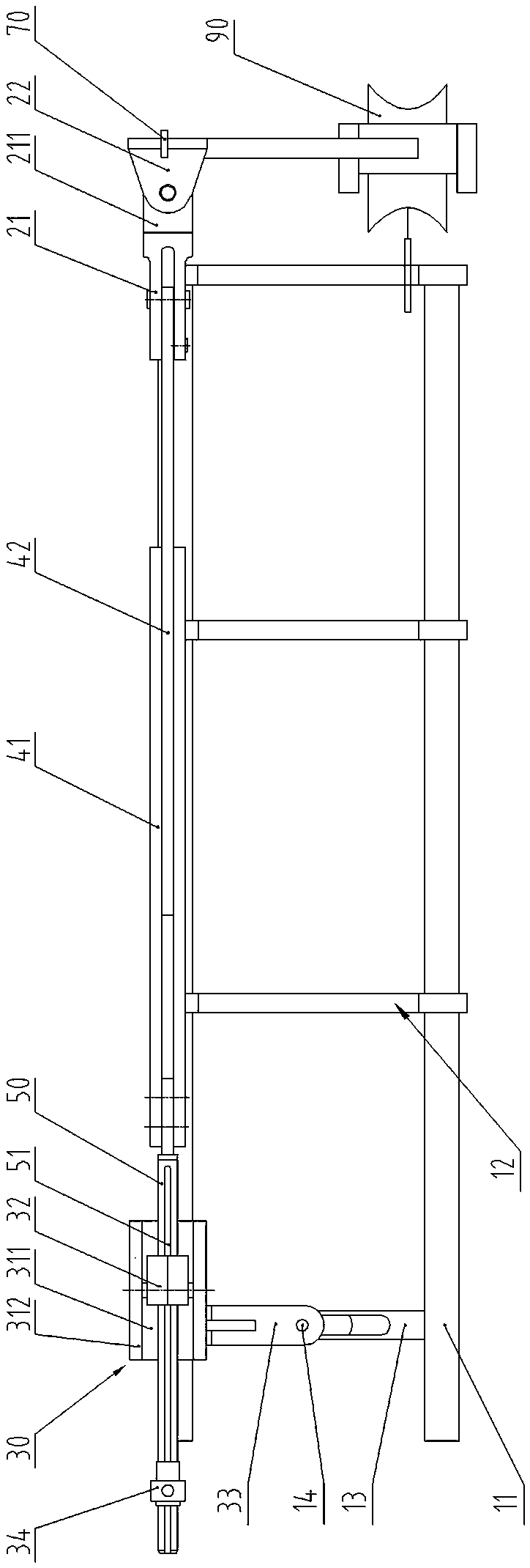

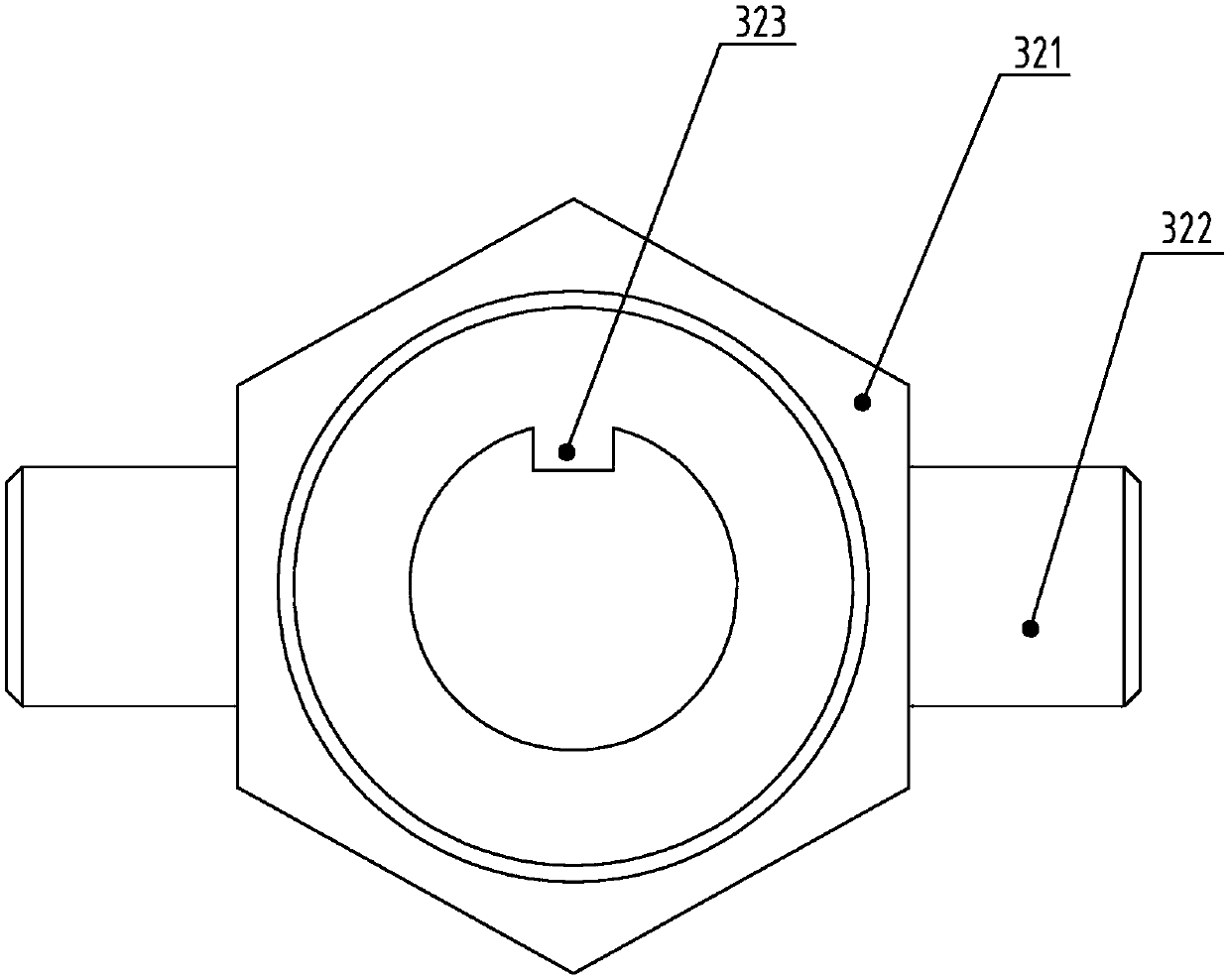

[0034] Such as Figure 1 to Figure 8 As shown, the present invention discloses a device for remote operation and replacement of double-strand double-string insulators of double-split lines, including a bottle holder 10, a wire end clamp 20, a cross-arm end clamp 30, a pull plate 40 and an adjusting screw 50 . One end of the pull plate 40 is connected to the cross-arm end clamp 30 through the adjusting screw 50, the other end is connected to the wire end clamp 20, and the bottle holder 0 is connected to the lower side of the insulator string.

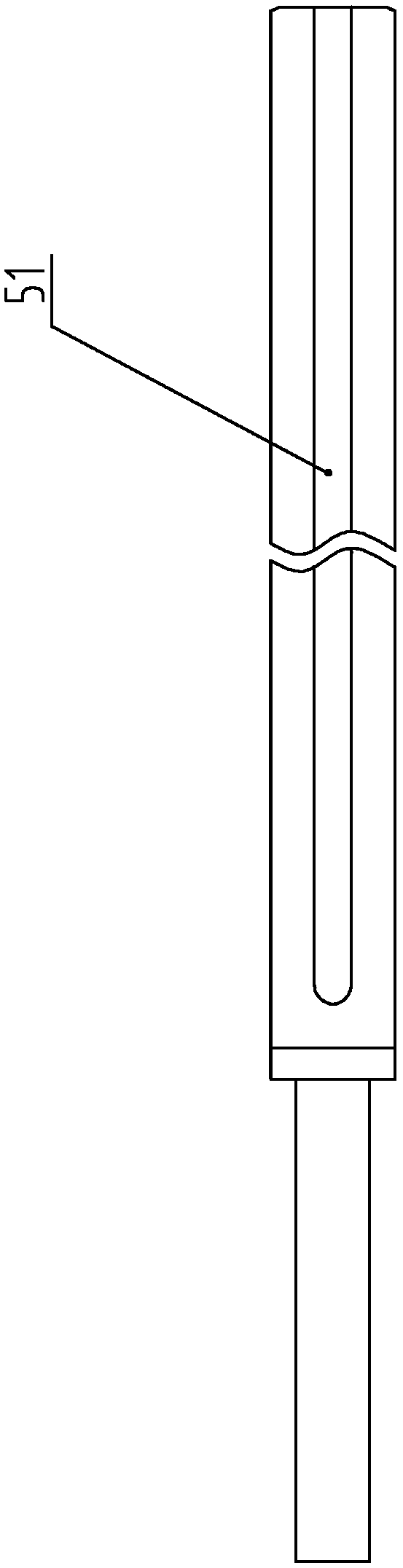

[0035] The pull plate 40 includes two opposite splints 41 and an adjustment plate 42 sandwiched between the opposite splints 41 . On the clamping plate 41 and the adjusting plate 42, connecting holes are arranged along the length direction, and one end of the adjusting plate 42 stretches between the clamping plate 41 and is fastened with it through the bolt passing through the connecting hole, and the other end of the clamping plate 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com