Six-axis jig

A jig and six-axis technology, applied in the jig field, can solve the problems of low degree of freedom of the jig, unable to meet production requirements, low motion accuracy, etc., and achieve the effect of wide application range, reasonable and reliable structure, and high motion accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

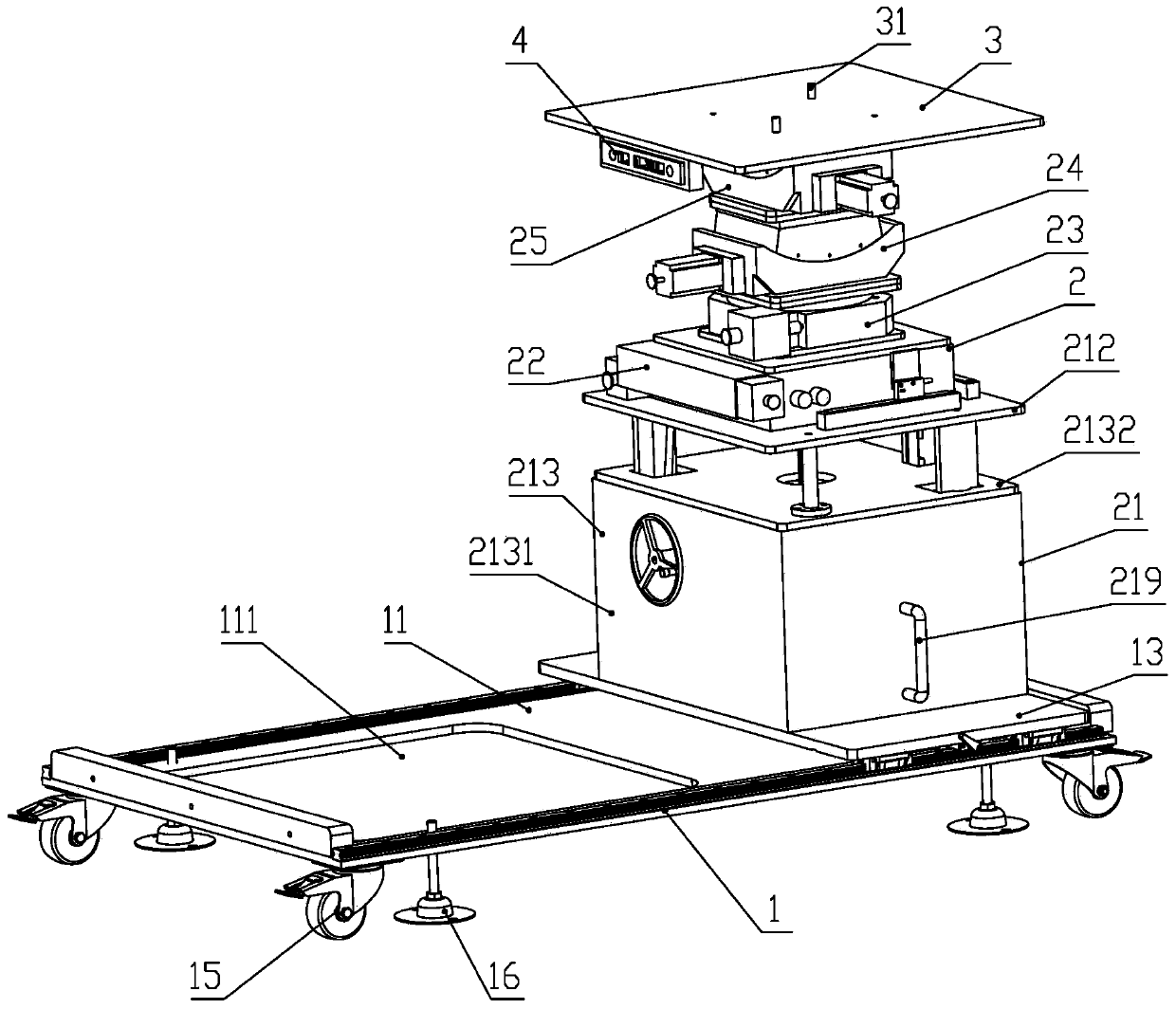

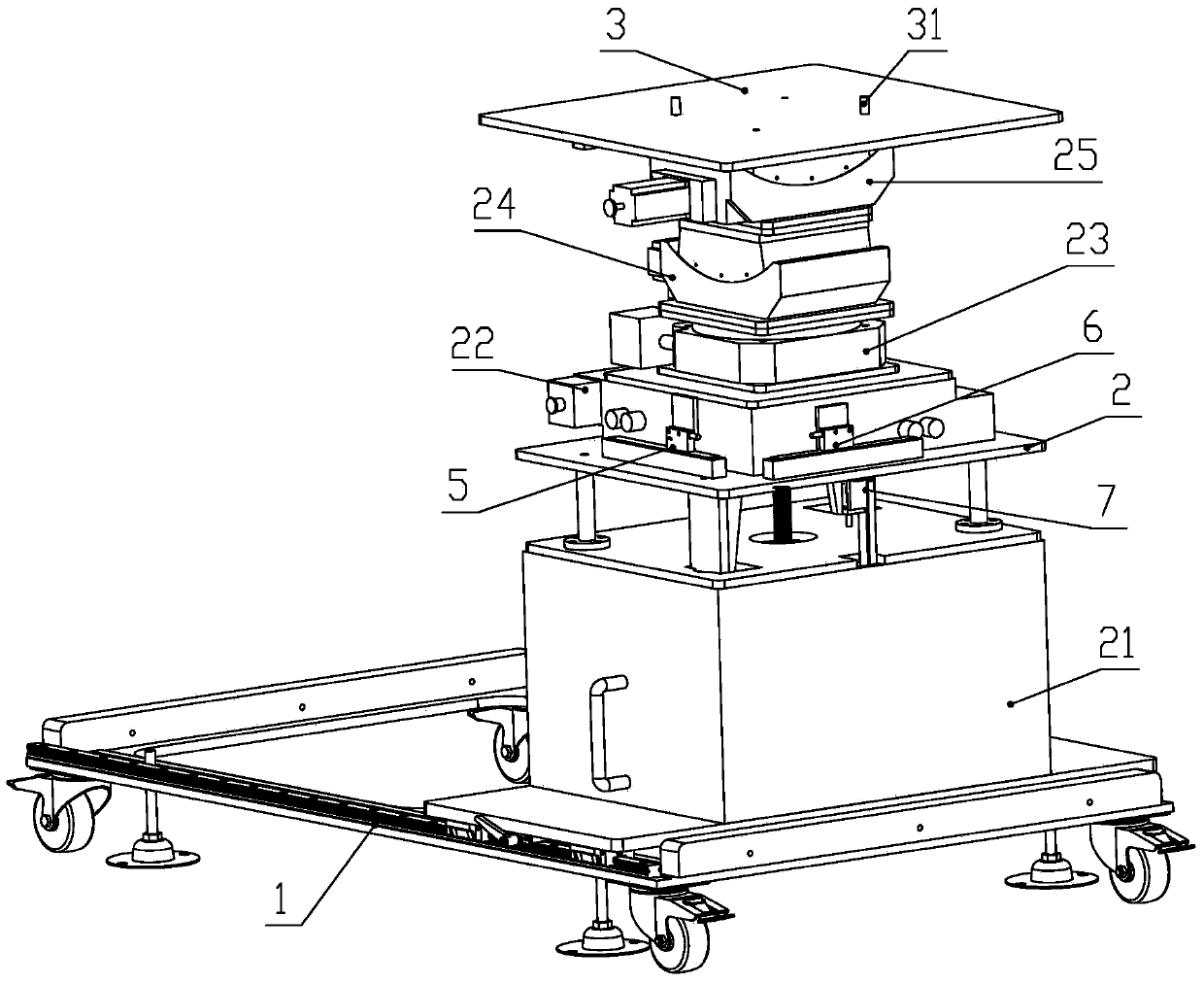

[0033] This embodiment provides a six-axis fixture, such as figure 1 and figure 2 As shown, the six-axis jig includes a base 1 , a six-axis driving device 2 arranged on the base 1 , and a module carrying platform 3 arranged on the six-axis driving device 2 .

[0034] The module carrying platform 3 has two cylindrical mounting positioning columns 31 arranged diagonally for quick module replacement.

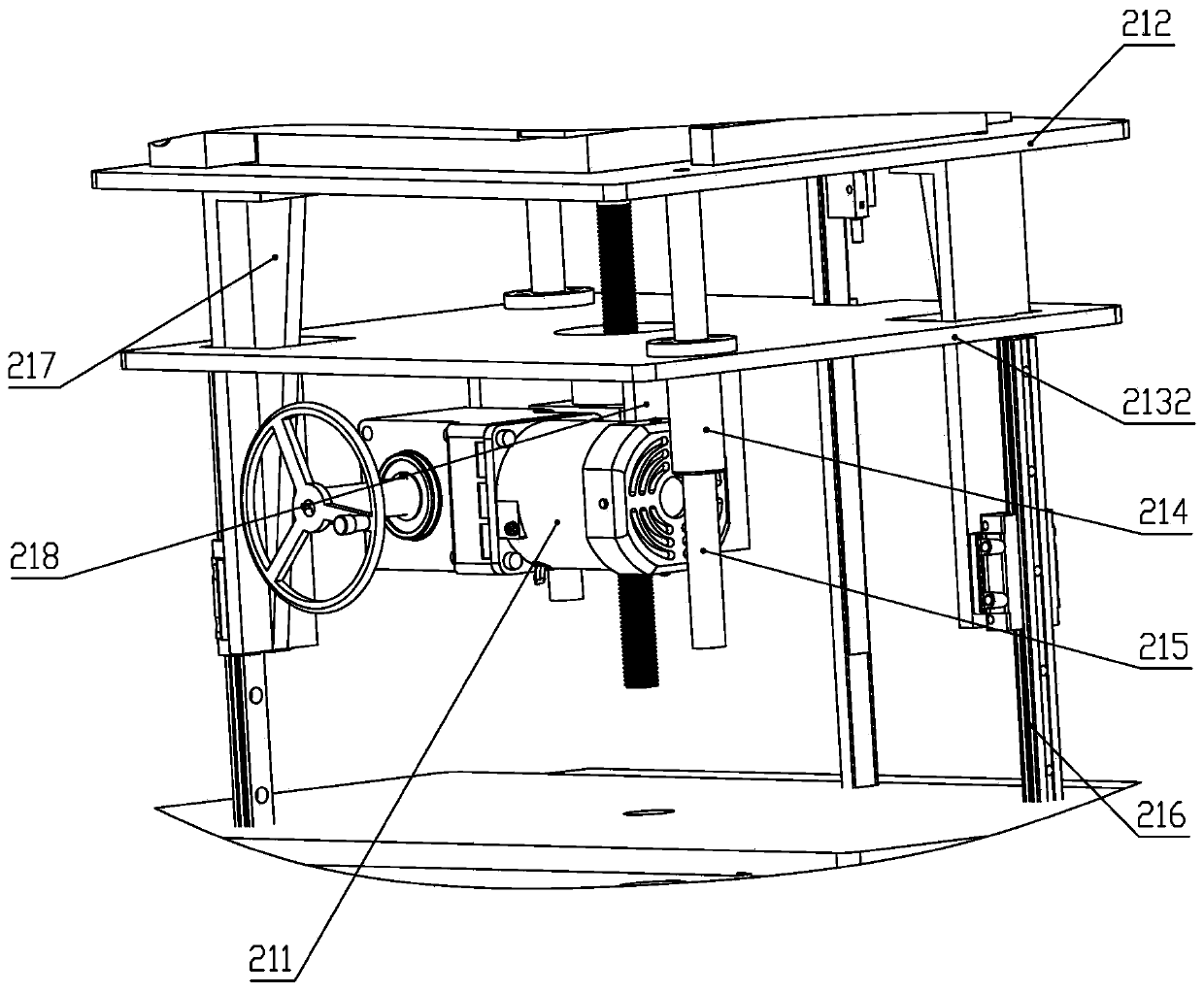

[0035] The six-axis driving device 2 sequentially includes a lifting device 21, an XY-axis moving platform 22, and 360 from bottom to top ° Rotary platform 23 , first angle platform 24 and second angle platform 25 . The lifting device 21 is used to drive the module carrying platform 3 to move up and down. The XY-axis moving platform 22 is used to drive the module carrying platform 3 to move along the first direction and / or the second direction perpendicular to the first direction within the plane where it is located. The 360° rotating platform 23 is used to drive the module ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com