Protofilament dryer of roller type structure

A dryer and raw silk technology, applied in dryers, progressive dryers, drying, etc., can solve the problems of long time, high cost, complex structure, etc., and achieve simple structure, low cost, and control production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

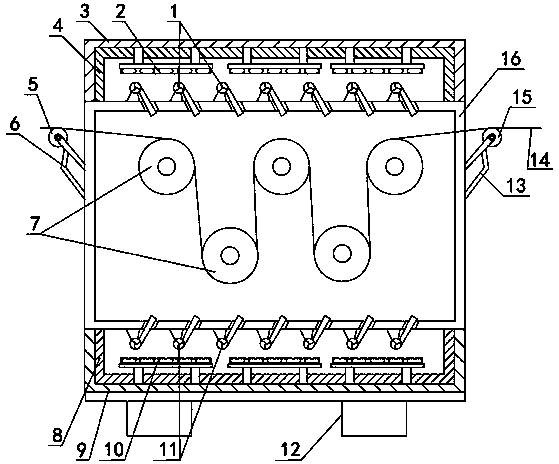

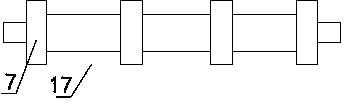

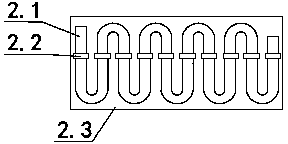

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the raw silk dryer with a roller structure includes a work panel 16 with a frame structure. The middle part of the work panel 16 is equipped with a winding roller 7 for winding the raw silk 14 up and down, left and right, and the bottom of the work panel 16 is provided with four supports. The legs 12 are respectively provided with a wire inlet and a wire outlet on the left and right sides of the work panel 16, and a feed roller 5 is provided corresponding to the ratio inlet, and the feed roller 5 is installed on the left side wall of the work panel 16 through the feed bracket 6 , the corresponding wire outlet is provided with a discharge roller 15, the discharge roller 15 is installed on the right side wall of the work panel 16 through the discharge bracket 13, and several upper fans 1 in an array of equal intervals are installed on the top of the work panel 16. The air outlet o...

Embodiment 2

[0028] This embodiment is changed on the basis of Embodiment 1, and the distance between the adjacent upper fans 1 is changed to 1000 mm; the distance between the adjacent lower fans 11 is changed to 800 mm. Others are the same as embodiment one.

Embodiment 3

[0030] This embodiment is changed on the basis of Embodiment 1, and the distance between the adjacent upper fans 1 is changed to 1200mm; the distance between the adjacent lower fans 11 is changed to 1100mm. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com