Mobile safety net hanging method for plant roof installation

A technology for installation of safety nets, which is applied to hoisting devices, clockwork mechanisms, buildings, etc., can solve the problems of labor-intensive installation of safety nets, affect the efficiency of roof construction, and the safety net cannot be moved, etc., so as to achieve fast deployment , simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, the present invention is further described:

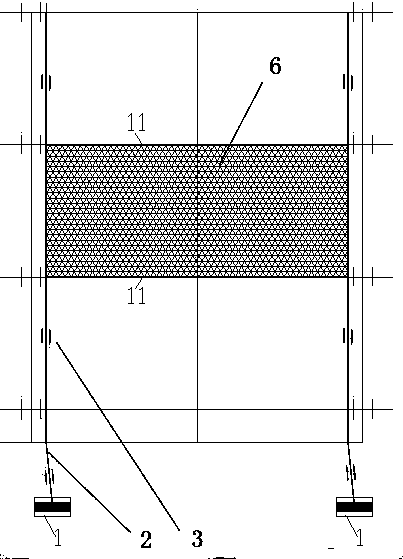

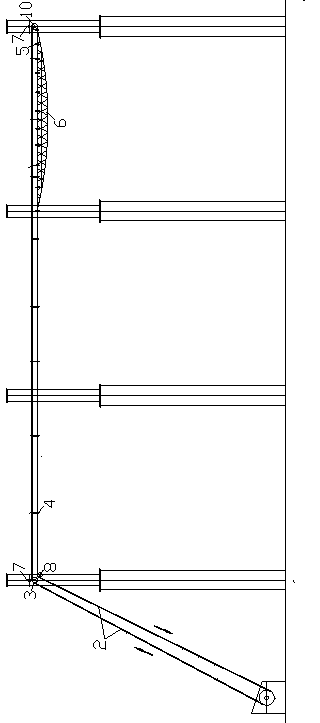

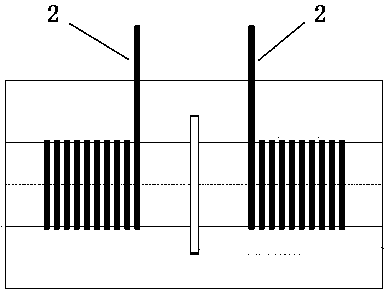

[0022] Such as Figure 1 to Figure 3 The shown method for hanging the mobile safety net on the roof of the factory building includes the following steps:

[0023] First of all, the hoist 1 is transformed, and the ordinary hoist is transformed into a double-purpose hoist 1: the hoist drum is divided into two halves with a steel plate, and the hoist wire rope 2 of a loop is wound on both sides, and the back and forth wire rope is formed when the hoist 1 rotates. a loop.

[0024] Outside the factory building area where the safety net needs to be hung, two winches are installed on the ground of the two opposite column feet (near the final installation area) in the same span; the two winches are connected by a linkage switch to play a role of synchronous control.

[0025] Set two pulleys on the two roof beams on the same axis in the factory building area where the safety net needs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com