A-class fireproof insulation decoration integrated hanging board for building exterior wall

A technology for fire prevention and heat preservation and building exterior wall, which is applied in the fields of heat preservation, building exterior wall fire prevention, and decoration, can solve the problems of large overall skeleton, unsatisfactory fire prevention effect, and many steel structure raw materials, etc., and achieves simple and fast installation and simple construction. , No peeling layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

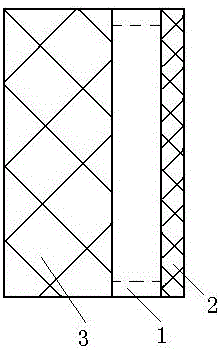

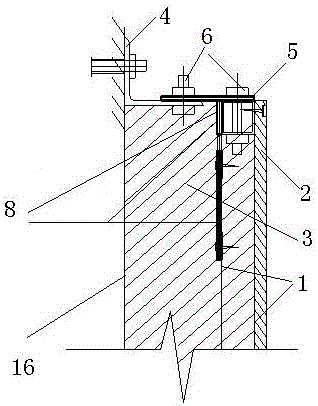

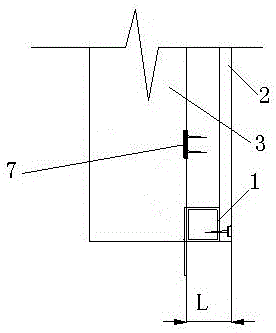

[0096] 1. First of all, according to the facade size and specific requirements of the building, carry out the plate design. Then according to the specific specifications and technical requirements of the product, use the tire mold made of special steel structure parts to carry out blanking, welding, and filling of insulation materials and anti-rust treatment on the light steel frame 1 of the hanging plate, so as to ensure uniform specifications and small errors ,reliable quality.

[0097] 2. According to the specific specifications of the product and according to the technical requirements, the panel 2 (cement panel, granite panel, marble panel, ceramic tile and other surface materials) is blanked and processed by special equipment. Ensure uniform specifications, small errors, and reliable quality.

[0098] 3. Install the light steel frame 1 and the cement panel 2 in the special installation mould. Ensure uniform specifications, small errors, and reliable quality.

[0099] ...

Embodiment 1

[0104] 1. The product specification is 600mm×1200mm.

[0105] 2. The light steel frame 1 is made of 25mm×25mm×1.5mm square steel pipe, and the inner filling density is 24kg / m³ rock wool board side strips. According to the installation requirements, the steel frame 1 is drilled, slotted, rust-removed and anti-rust and other processes deal with.

[0106] 3. Panel 2 is made of δ=10mm thick high-density cement pressure plate, connected and fixed with light steel frame 1 with self-tapping screws, and the nail holes are smoothed with cement glue (the top of the nail is not visible from the outside).

[0107] 4. The insulation material of insulation layer 3 adopts special glass wool for curtain wall insulation with a bulk density of 12~24kg / m³, a thermal conductivity of 0.034~0.036W / m².K, a thickness of 10mm (practical 90mm), and a combustion performance of the insulation material. plate. Use self-adhesive to stick firmly to the back of panel 2 cement board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com