Integral electric spindle support for viscose spinning machine

A viscose fiber and electromechanical ingot technology, applied in textiles and papermaking, etc., can solve problems such as heavy installation, use and maintenance workload, troublesome installation and maintenance, complicated level adjustment, etc., to achieve fast use and maintenance, easy installation and maintenance Convenience, the effect of stable and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

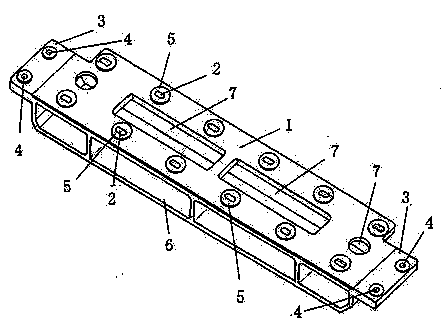

[0014] figure 1 Shown: The electric spindle support used for installing the viscose fiber spinning machine is a long strip-shaped integral support body 1, and several circular through holes for installing electric spindles are distributed in two rows on the support body 1 2. There are several base connection holes 4 at both ends of the support body 1 . Several circular through holes 2 distributed in two rows are located in the middle of the respectively provided bosses 5 . Several base connection holes 4 are provided on the ear plates 3 at both ends of the support body 1 . A supporting bottom plate 6 is connected below the support body 1 . The bracket body 1 and the supporting bottom plate 6 below are provided with several corresponding communication holes 7 for weight reduction and heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com